Safety structure of a power battery pack

A power battery pack and safety structure technology, applied to battery pack parts, structural parts, circuits, etc., can solve problems such as temperature rise of faulty batteries, explosion of faulty batteries, hidden dangers of normal operation of battery packs, etc., to ensure anti-vibration capability , preventing proliferation and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

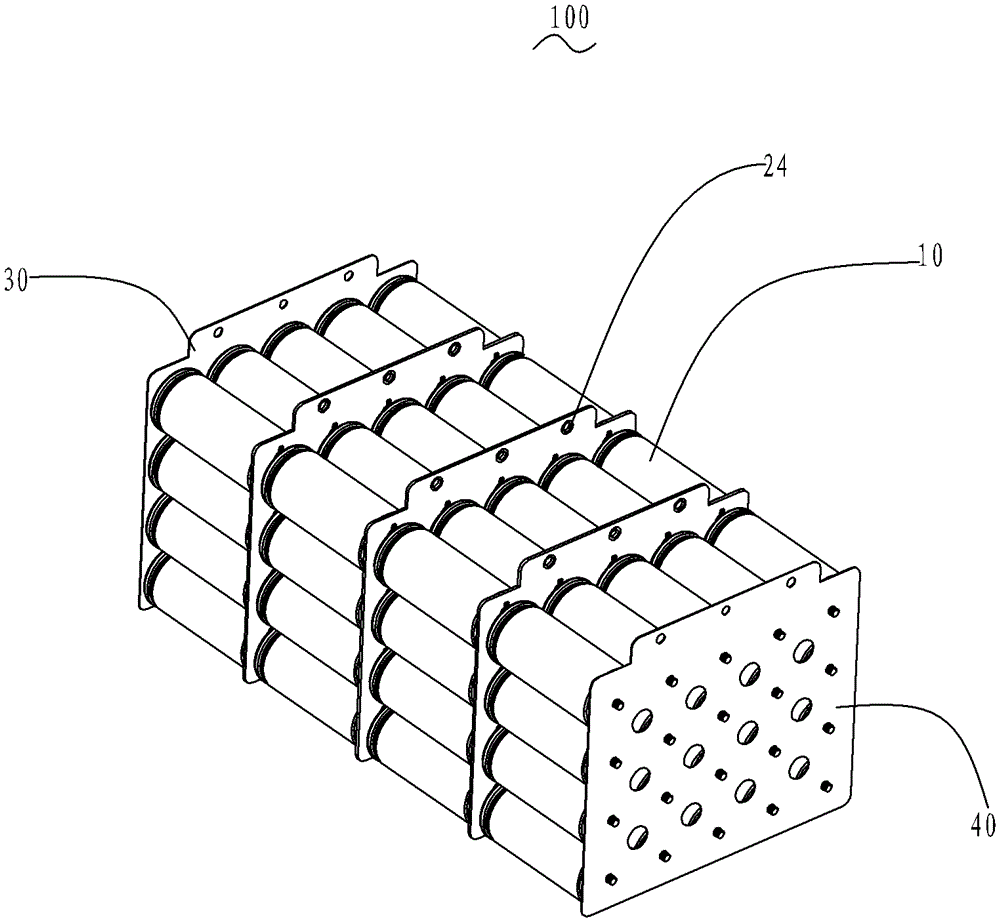

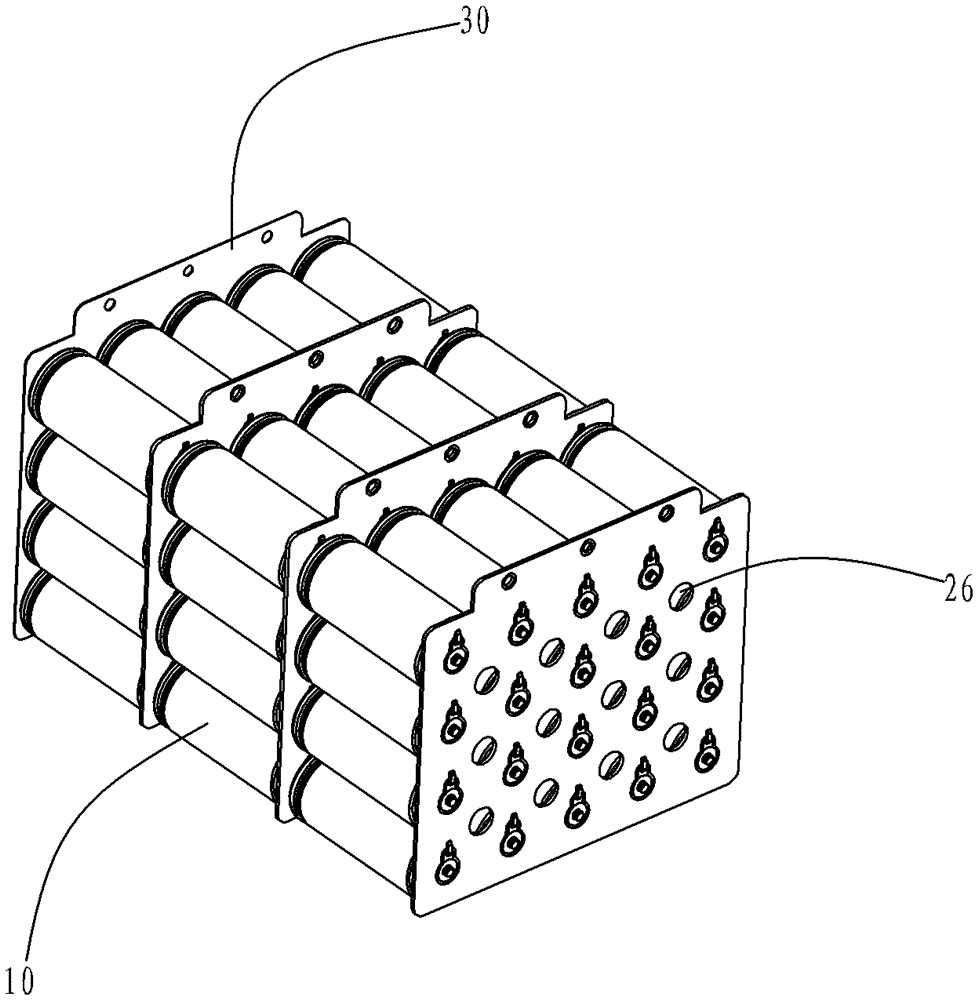

[0023] Please refer to Figure 1 to Figure 4 As shown, the present invention is a safety structure of a power battery pack. The battery pack 100 includes M layers of single cells 10 arranged in an N×P matrix, and each adjacent two layers of single cells 10 are correspondingly connected in series. A reinforced circuit board 20 is connected between every two adjacent layers of single cells 10 , and the electrodes of the topmost and bottommost single cells of the battery pack 100 are respectively connected to the general positive plate 30 and the general negative plate 40 .

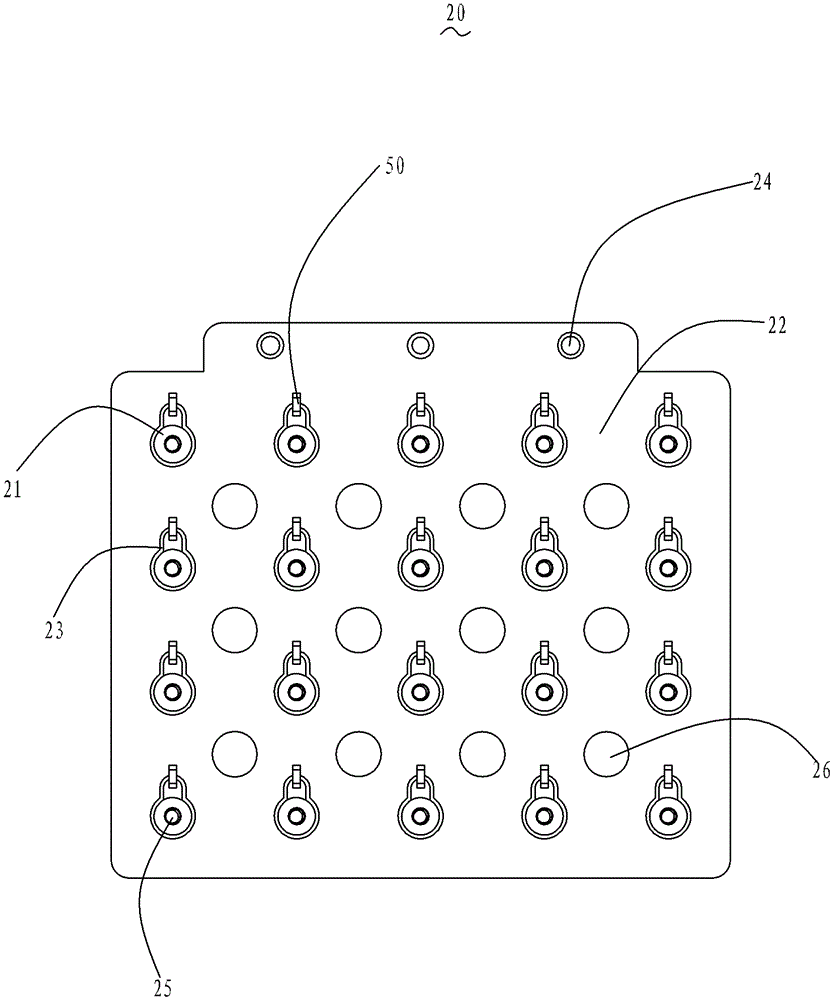

[0024] The reinforced circuit board 20 is roughly rectangular, and includes N×P electrode connection pieces 21 for connecting the polarity of the single battery 10 (the polarity can be divided into positive and negative), and a conductive main board 22 for insulating and isolating the electrodes. The connecting sheet 21 and the insulator 23 of the conductive main board 22 . The tops of the reinforced circui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com