Magnetron drive power supply for industrial microwave equipment

An industrial microwave and drive power technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of reducing heat dissipation effect, electrical safety hazards, electrical accidents, etc., achieve good heat dissipation effect, easy safety requirements, and meet safety regulations required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

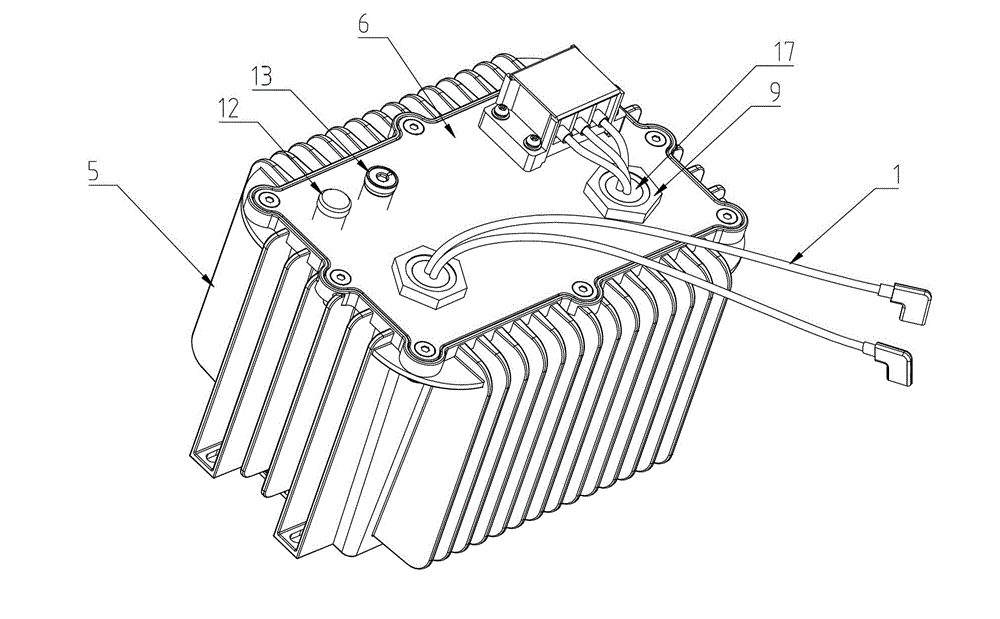

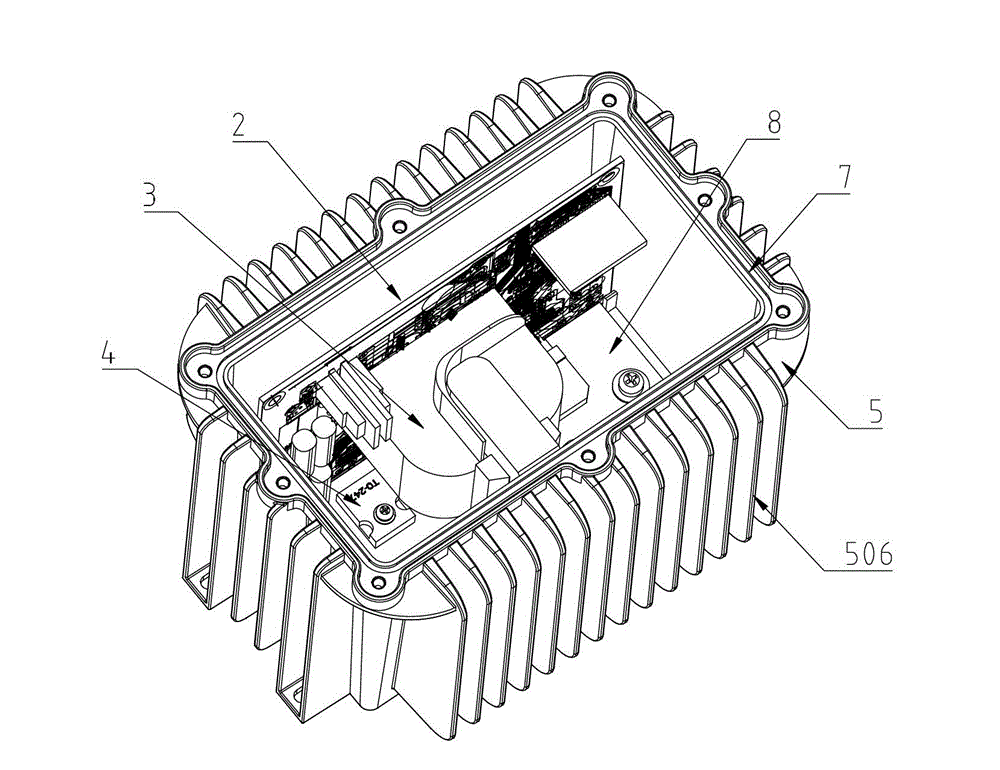

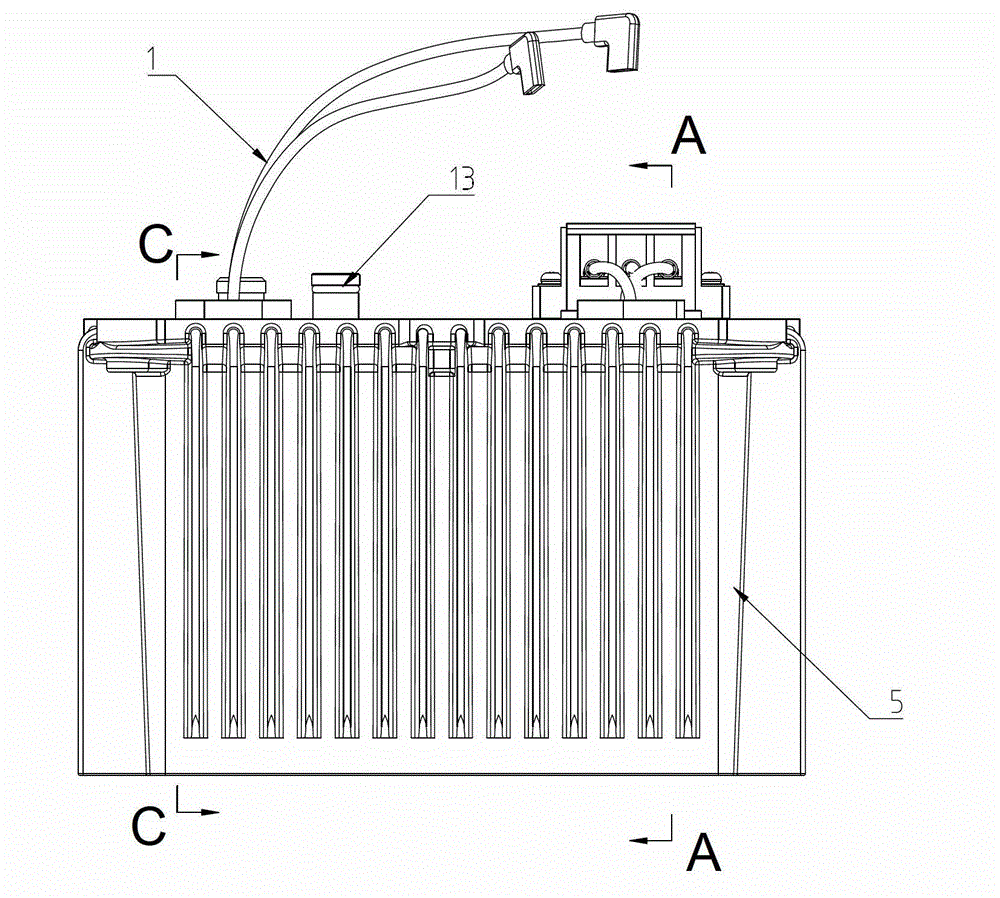

[0032] Such as Figure 1 to Figure 15 As shown, the magnetron drive power supply for industrial microwave equipment includes input and output cables 1, a circuit board 2, a heat conducting plate 8, electrical components and an oil tank.

[0033] The cable 1 is welded to the circuit board 2, and the components include a transformer 3 and power components 4 (IGBT, rectifier).

[0034] The oil tank includes a box body 5 and a cover plate 6, and the cover plate 6 is fixed on the opening at the upper end of the box body 5 by screws. Cooling oil is filled in the oil tank, and the circuit board 2 and components are all immersed in the oil in the oil tank. The rubber ring 7 is used to seal the case body 5 and the cover plate 6 .

[0035] The circuit board 2 is vertically arranged in the fuel tank, and the projected area in the Z-axis direction is small, so that the area occupied by the power supply can be reduced.

[0036] The box body 5 is a die casting, and the outside of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com