Method for producing a piezo actuator and piezo actuator

A technology of piezoelectric actuators and piezoelectric stacking, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive device manufacturing/assembly, circuits, etc., can solve time-consuming and high-cost problems problems to achieve high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

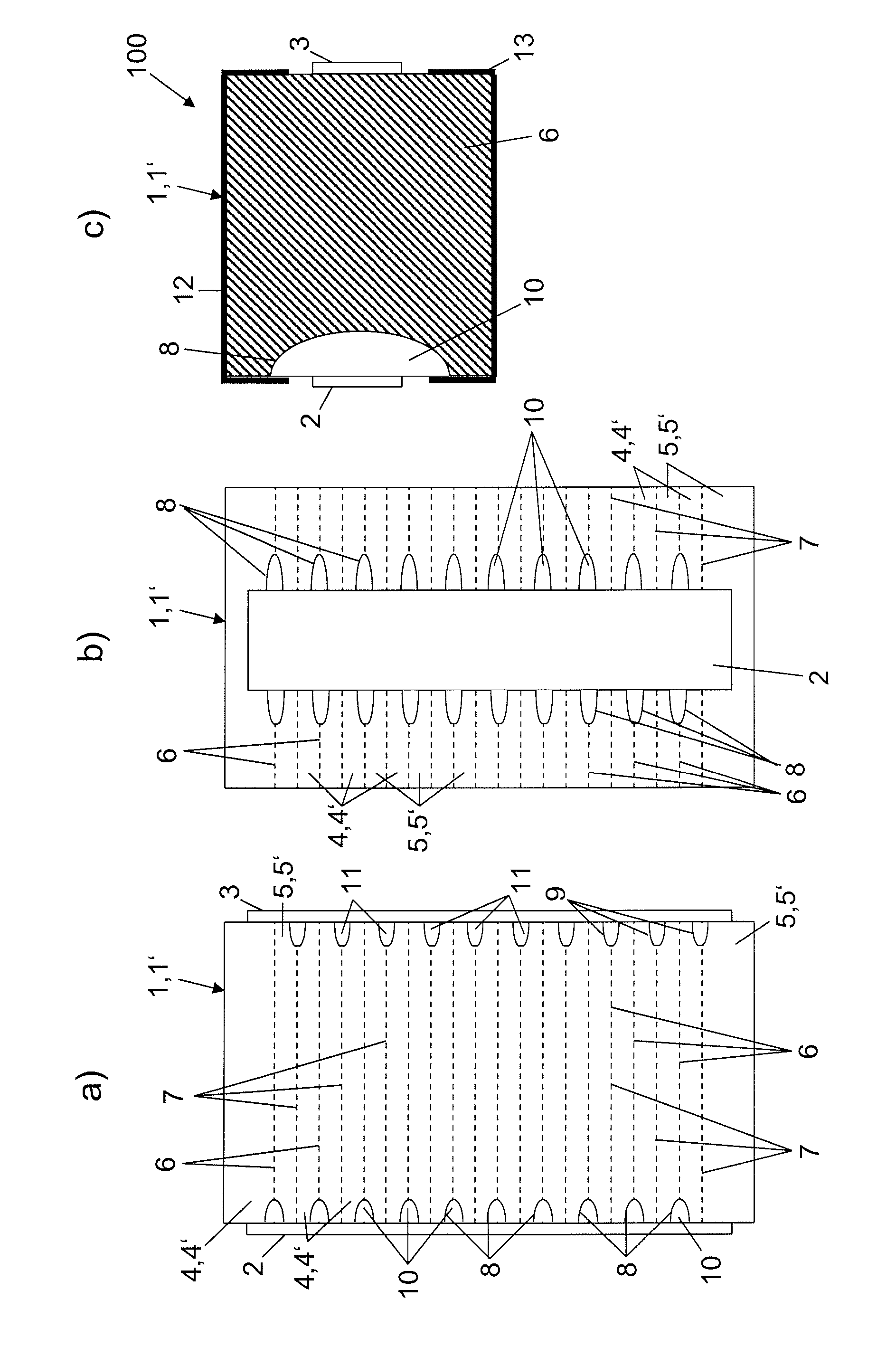

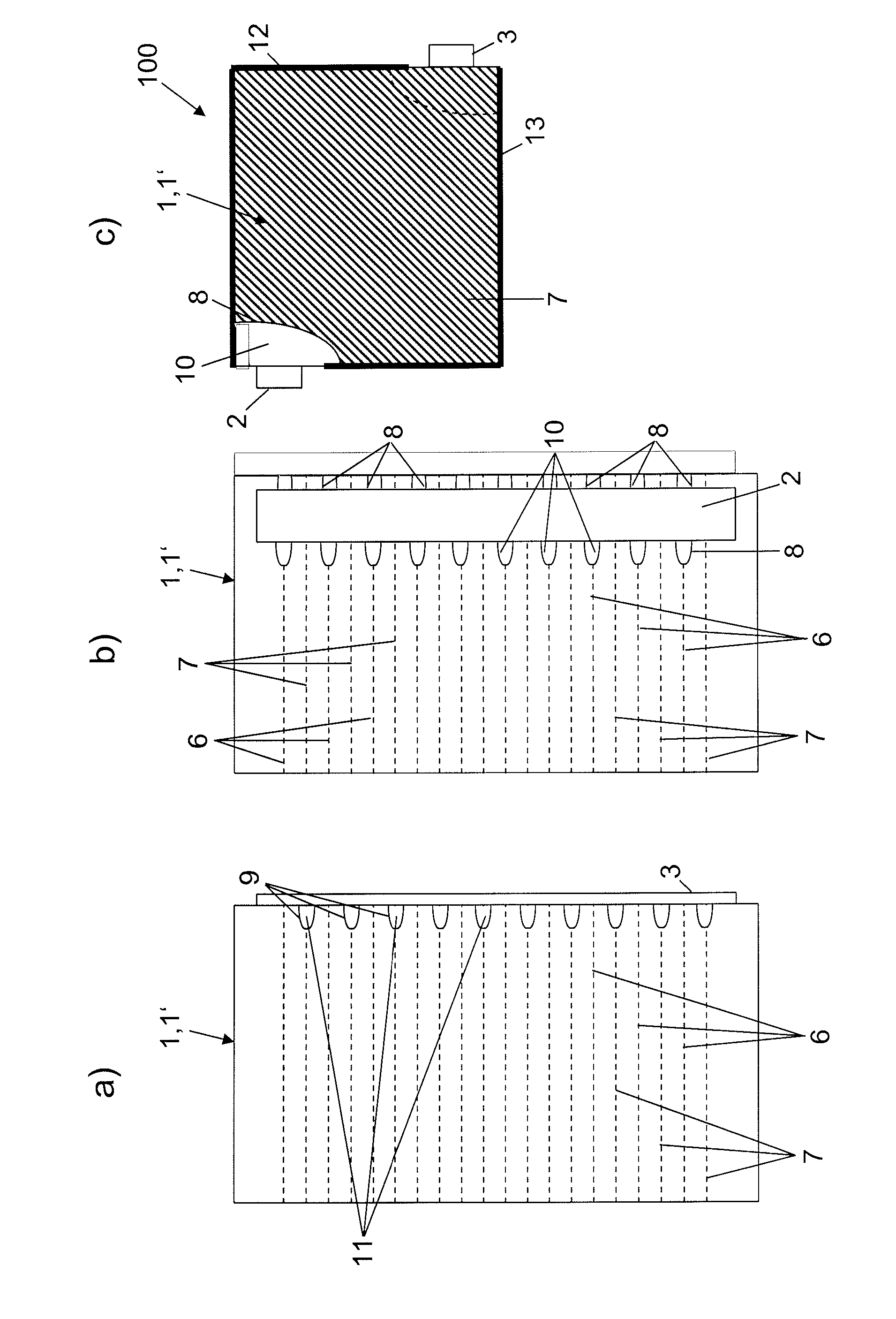

[0033] In the case of the current example, in figure 1 with 2 The starting point of the piezo actuator 100 shown in is a fully active green stack 1 ′, each embodied as a square in top view, with a plurality of green films 4 ′, 5 ′ and an internal electrode layer 6 arranged in between , 7 (see figure 1 c) and 2c)). The green stack 1' is produced in a generally known manner by an alternating stack of internal electrode layers and green films. The green films 4', 5' comprise piezoelectric ceramic materials, such as lead zirconate titanate. The internal electrode layers 6 , 7 are, for example, electrically conductive metal layers which pass continuously through the green stack 1 ′, ie are formed continuously up to the outside of the green stack 1 ′, so that the green stack 1 ′ initially has no Inactive regions, but only active regions. The inner electrode layers 6 , 7 are provided for electrical connection alternately with the two outer electrodes 2 , 3 arranged on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com