Corn seed directional separation spacing seed-arrangement device and operation method thereof

A seeding device and directional separation technology, applied in the field of agricultural machinery, can solve the problems of corn seeds without pre-processing, corn kernel damage, and difficulty in direct sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

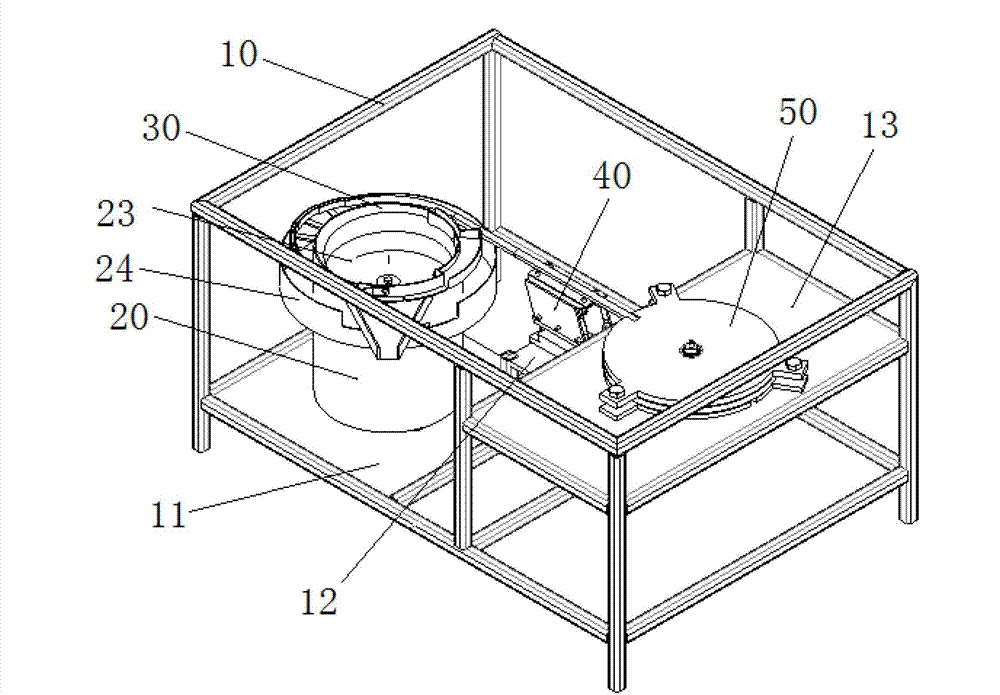

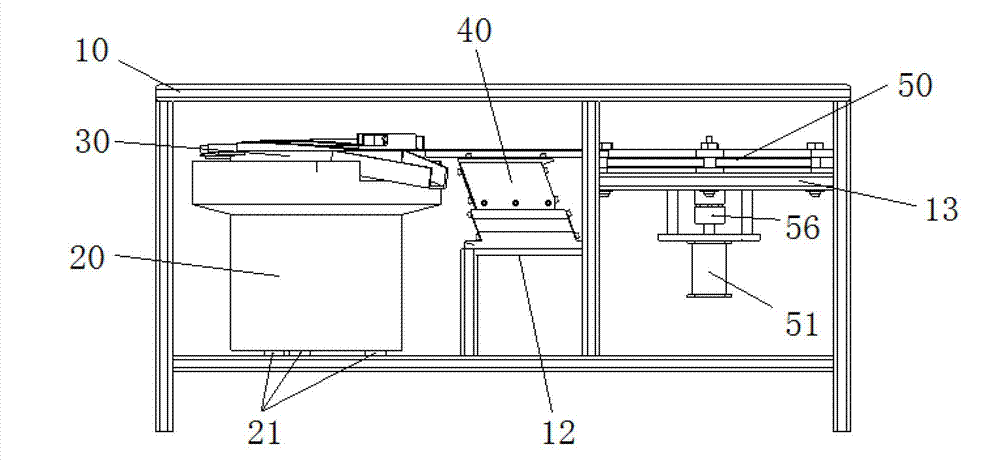

[0029] Such as figure 1 , figure 2 As shown, the present invention includes a support 10 , an electromagnetic vibrating device 20 , a directional seeding passage 30 , a straight line conveying passage 40 and a separation distance device 50 .

[0030] One side of the bracket 10 of the present invention is provided with a bottom plate 11 , the middle part is provided with a support frame 12 , and the upper part of the other side is provided with a support base 13 .

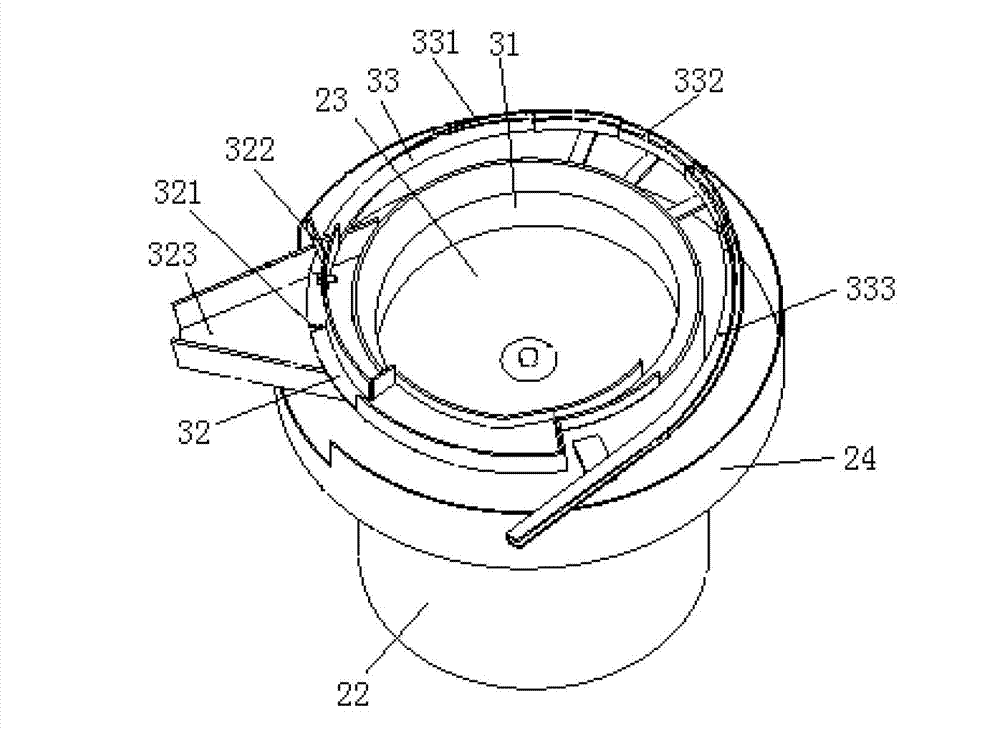

[0031] The electromagnetic vibrating device 20 of the present invention comprises a vibration-damping support 21 fixed on the base plate 11, a prior art electromagnetic vibration source 22 is arranged on the vibration-damping support 21, and a convex plate 23 is arranged on the top of the electromagnetic vibration source 22 , The outer edge of the chassis of the convex plate 23 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap