Drum type rotary filter

A technology of rotary filter and filter, which is applied in the direction of mobile filter element filter, filter separation, chemical instrument and method, etc. It can solve the problems of high cost of removing filter residue, inconspicuous filtering effect, incomplete particle removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

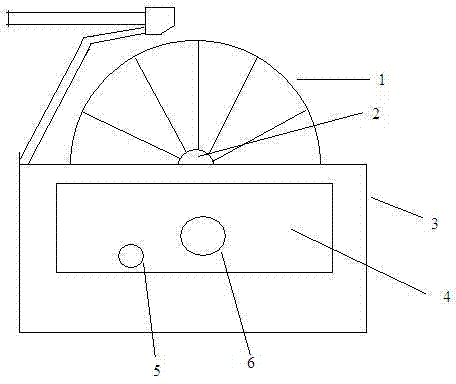

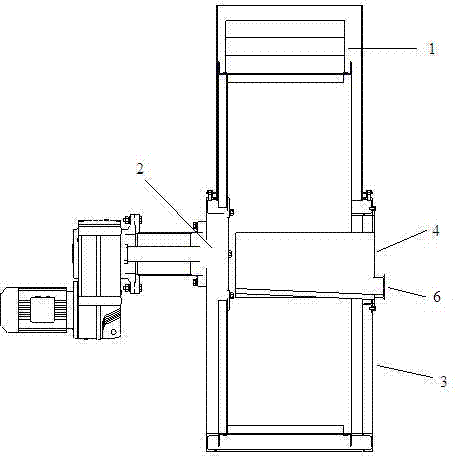

[0016] Such as figure 1 As shown, the drum-type rotary filter includes a drum 1 covered with a filter screen, and sprays the liquid to be filtered on the drum from above the drum, such as figure 1 As shown in the spray nozzle (not marked with the icon), because there is an impulse when spraying, the filtrate will pass through the filter and fall into the sink 4 installed on the frame 3 in an instant. The drum 1 is fixedly connected with the rotating shaft 2. The rotating shaft 2 is connected to a motor, and the motor is used to provide a power source for the filter. The rotating shaft 2 is installed and supported on the frame 3 and drives the drum 1 to rotate through the rotating shaft 2. The edge of the drum 1 has a peripheral edge extending outward, and the liquid to be filtered sprayed from above falls into a groove composed of the peripheral edge and the filter screen to form a containing space, so that the liquid will not spill to both sides. At the same time, the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com