Cutting torch lifting mechanism of cutting machine

A cutting machine and cutting torch technology, applied in the field of industrial cutting equipment, can solve the problems of no anti-collision device, high cost, affecting the quality of cutting, etc., and achieve the effect of reducing design cost and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope expressed by the specific embodiments.

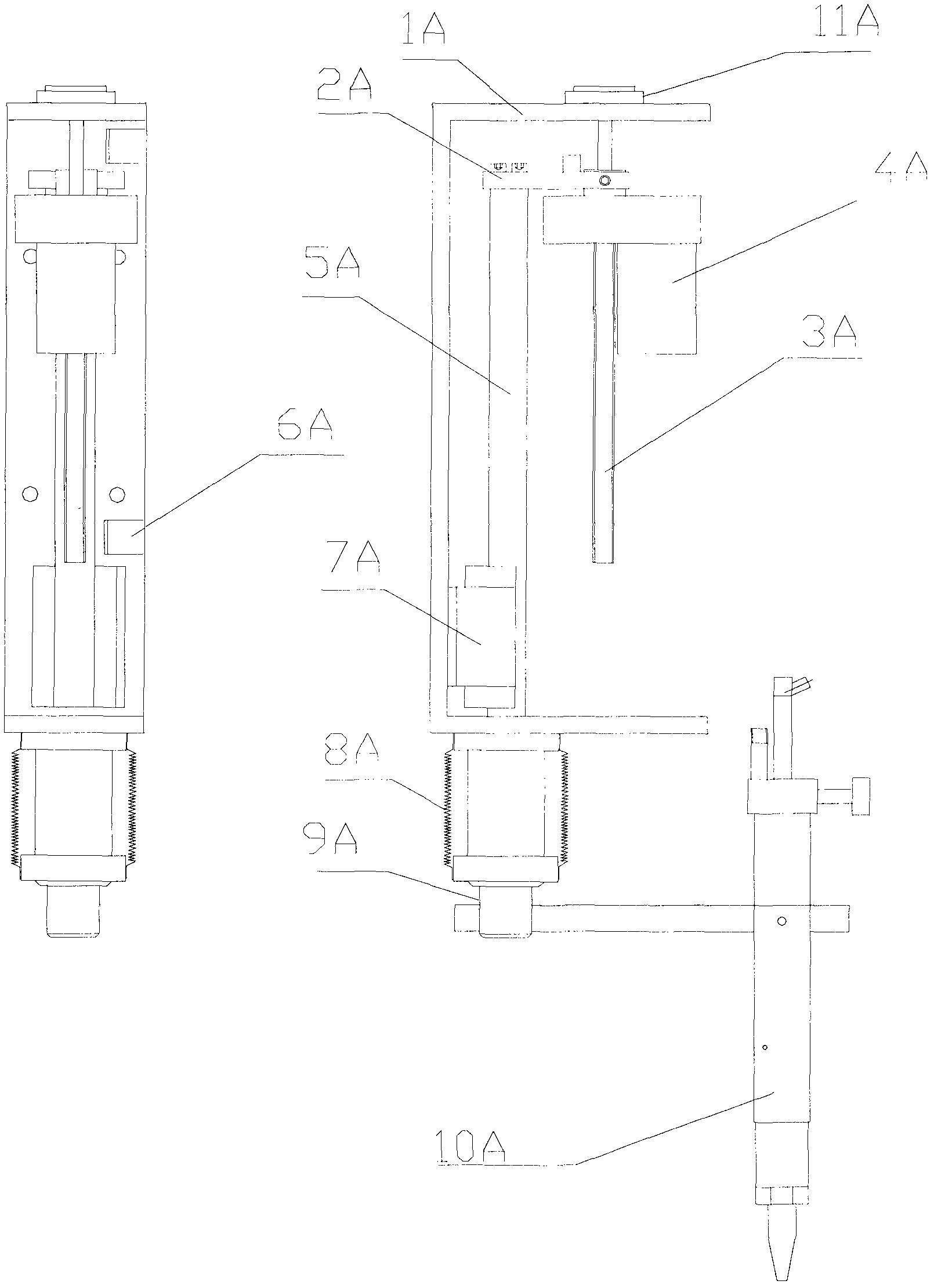

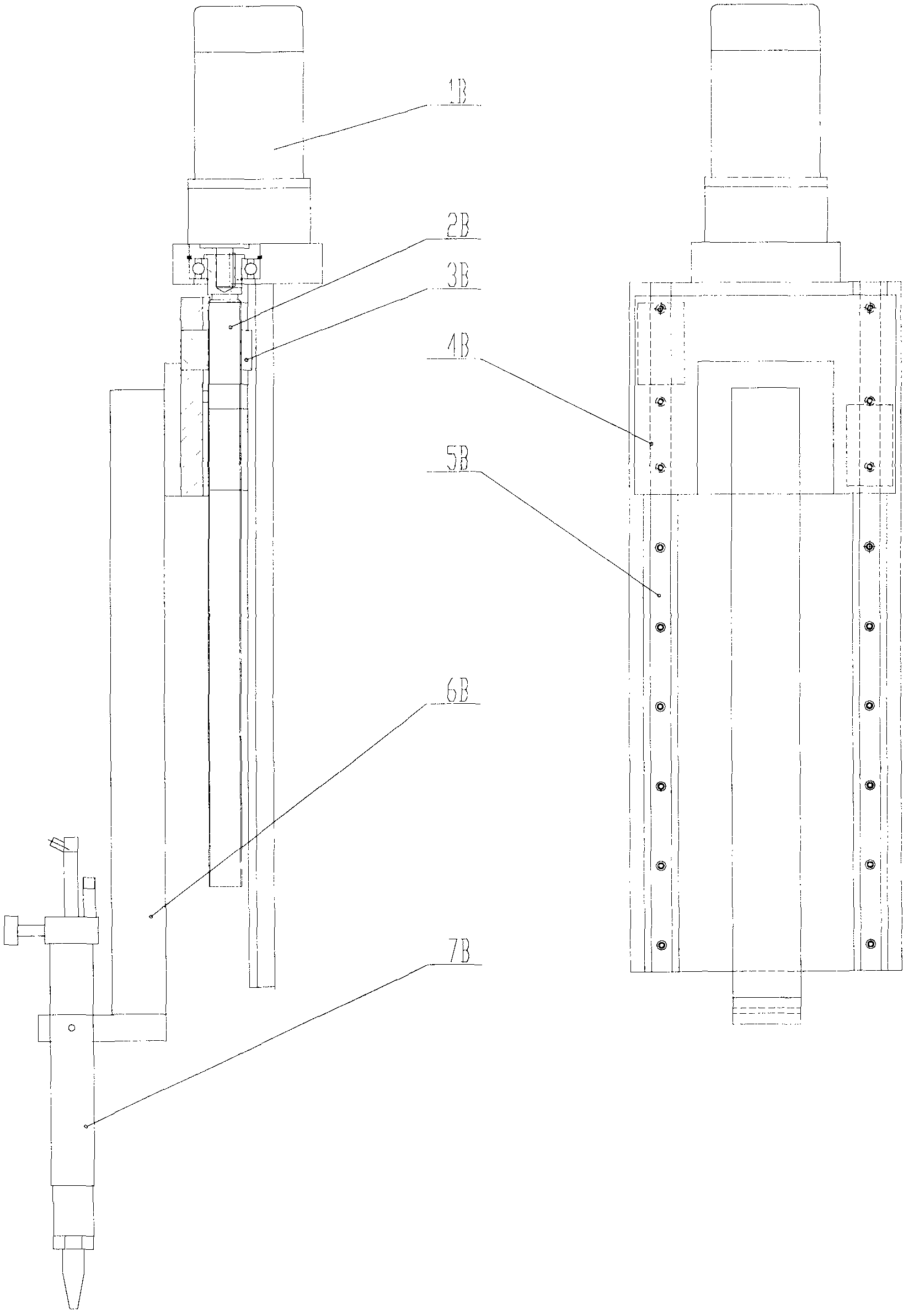

[0027] Cutting machine torch lifting mechanism, including frame 1A, connecting plate 2A, screw rod 3A, driving device 4A, linear guide rail 5A, guide rail slider 7A, telescopic dust cover 8A, transition rod 9A and cutting torch 10A.

[0028] Among them, the connection plate 2A, the screw rod 3A, the driving device 4A, the linear guide rail 5A, the telescopic dust cover 8A, the transition rod 9A and the cutting torch 10A are not connected with the frame 1A;

[0029] The screw mandrel 3A passes through the driving device 4A, the connecting plate 2A and the frame 1A sequentially from bottom to top, and the end of the screw mandrel 3A with an elastic washer 11A is suspended on the frame 1A; the driving device 4A and the The connecting plate 2A is connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com