Double-plate swirling rectification anti-drag stabilizer of speed boat

An anti-rolling device and technology for speedboats, which are applied to ships, transportation and packaging, and equipment for reducing ship motion, etc., can solve the problems of adverse effects of speedboats' state and speed, increased forward resistance of speedboats, and unsatisfactory anti-rolling effects, etc. , to achieve the effect of improving the hydrodynamic performance defects of the boat bottom, compact structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

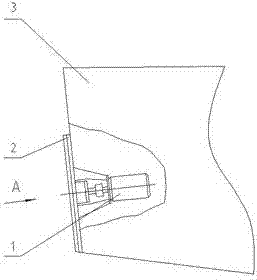

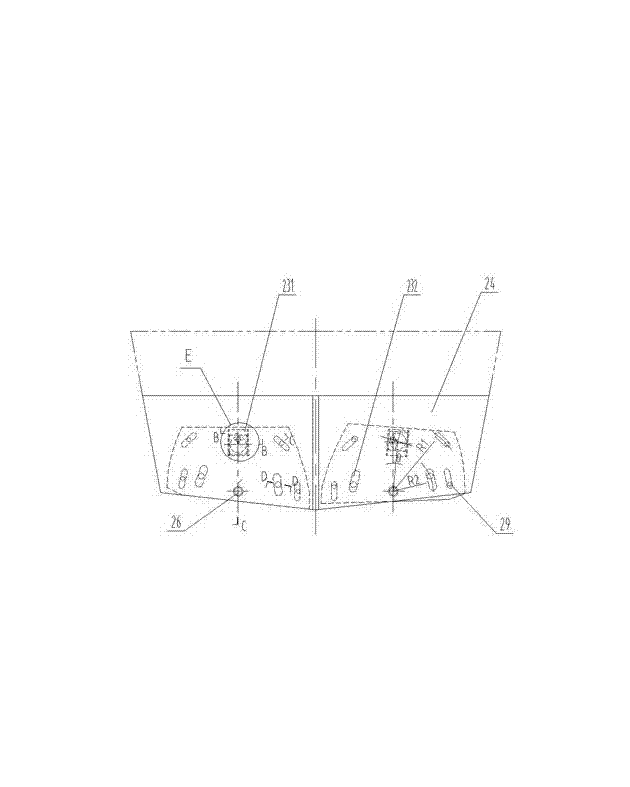

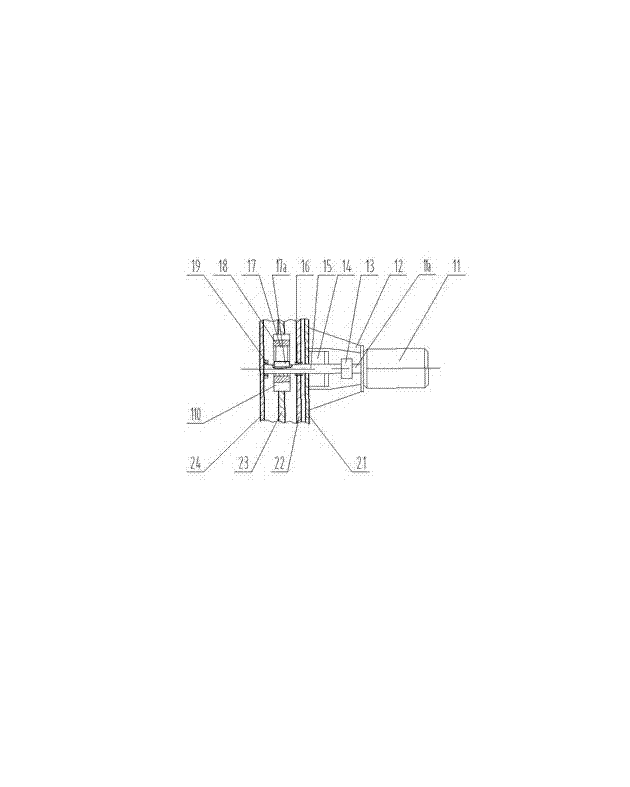

[0021] Such as Figure 1 to Figure 8 As shown, this embodiment includes two sets of drive mechanisms 1 and two sets of actuators 2, the drive mechanism 1 is symmetrically arranged on both sides of the speedboat stern 3, the actuator 2 is symmetrically arranged on the outer sides of the speedboat stern 3, and the actuator 1 Connect with drive mechanism 2. The driving mechanism 1 includes a stepping motor 11, a driving shaft 15, an eccentric wheel 17, a driving slider 18 and a pair of vertical slide rails 110, and the actuator 2 includes a base plate 22, a cover plate 24, a rectifying plate 23, a spindle bearing 25, Mandrel 26, several anti-warping pins 27, several pairs of vertical slide rails 211, several end surface sliders 27 and several pairs of smooth rails 28. The power source of the driving mechanism 1 is a stepper motor 11, and the stepper motor 11 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com