Novel drip-proof liquid feeding nozzle

A technology of injection nozzle and liquid, which is applied in the field of new liquid anti-drip injection nozzle, can solve the problems of waste of resources, troublesome processing, dripping, etc., and achieve the effect of improving work efficiency, simple structure and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

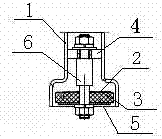

[0013] refer to figure 1 , a new type of anti-drip injection nozzle for liquid, comprising a feeding pipe 1, a fastening assembly, a gasket 2 and an edible sponge 3, the gasket is arranged on the upper surface of the edible sponge 3, and the edible sponge 3 is fastened The assembly is placed inside the fill tube. The fastening assembly includes a fixed plate 4, a supporting plate 5 and a bolt 6, the fixed plate 4 is fixed in the injection pipe 1, the supporting plate 5 is fixed on the discharge end of the injection pipe 1, and the bolt 6 One end runs through the fixing plate 4, and the other end is fixedly connected with the supporting plate 5, and the edible sponge 3 is placed on the supporting plate 5 horizontally. The diameter of the discharge section of the injection pipe 1 is larger than the diameter of the injection section. The fixing plate 4 and the supporting plate 5 are hollow mesh structures.

[0014] With the above technical solution, under the action of the fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com