Container wharf operation and management method

A management method and container technology, applied in the field of operation management, can solve the problems affecting the scheduling of collection trucks, the reduction of work efficiency, and the difficulty of dispatching personnel at the terminal, so as to achieve the effect of improving service efficiency, increasing use efficiency, and improving service level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

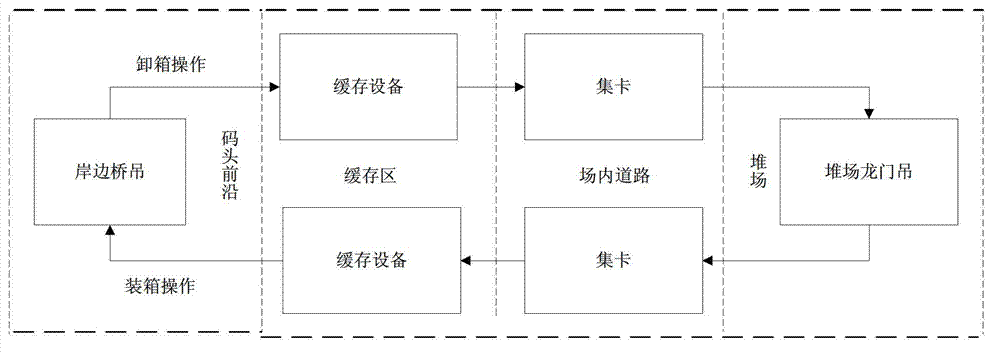

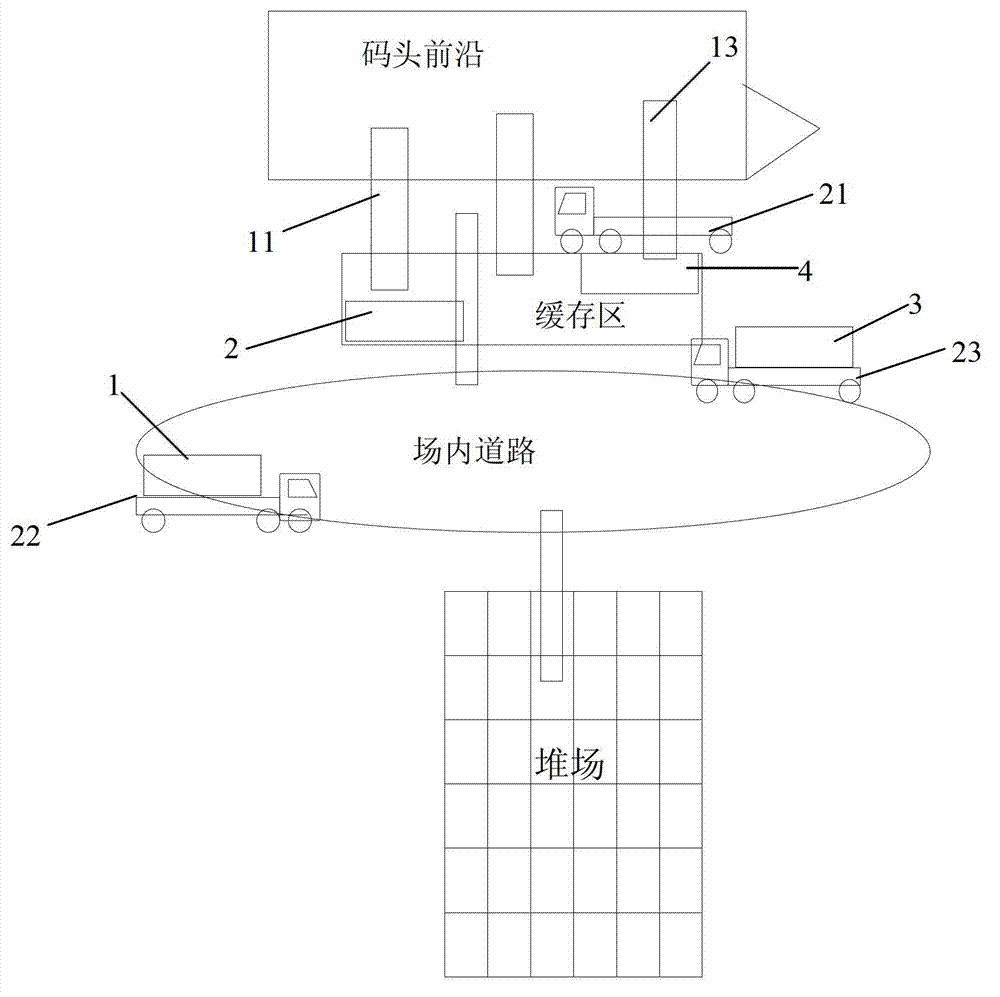

[0012] Such as figure 1 As shown, the site adopted by the container terminal operation and management method of the present invention includes the front of the terminal, the buffer area, the road in the site, and the storage yard. Collector trucks (container transport vehicles), and gantry cranes are installed in the yard. The horizontal lifting equipment can be a gantry crane or an empty container stacker for empty container operations. The horizontal lifting equipment can independently carry out the horizontal lifting operation of the container, or use the existing railway track at the front of the wharf to unload the container. Boxing and boxing operations, and can also meet the needs of railway transportation to realize water-iron (hot metal) combined transportation. Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com