Self-loading operation mechanism of loading machine

An operating mechanism and self-loading and unloading technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient operation and poor stability, and achieve the effects of convenient operation, improved work efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

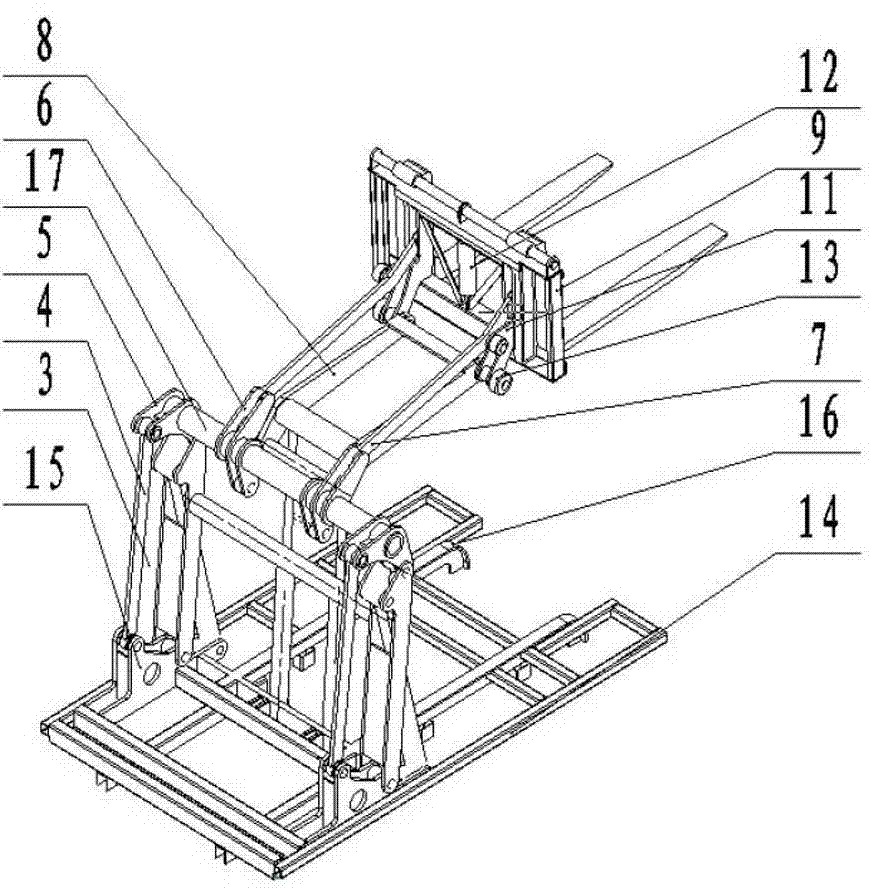

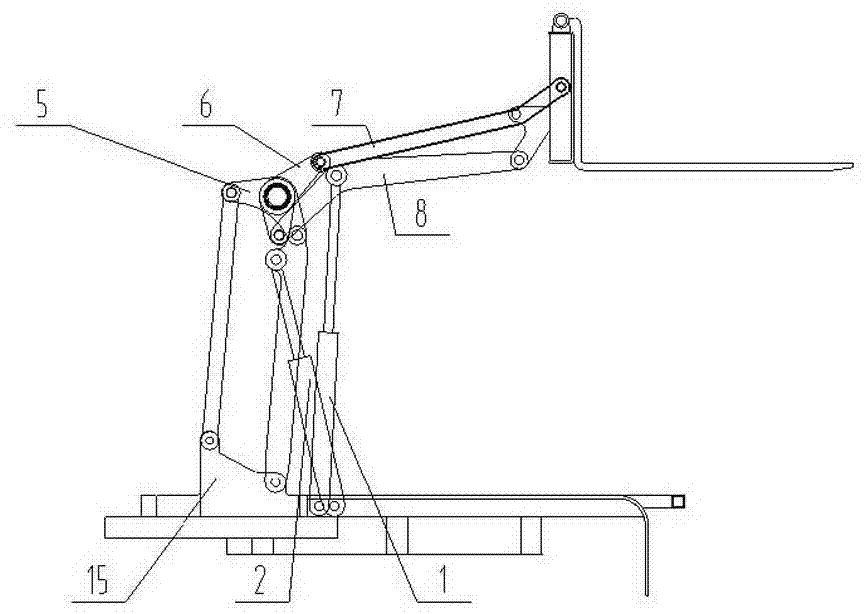

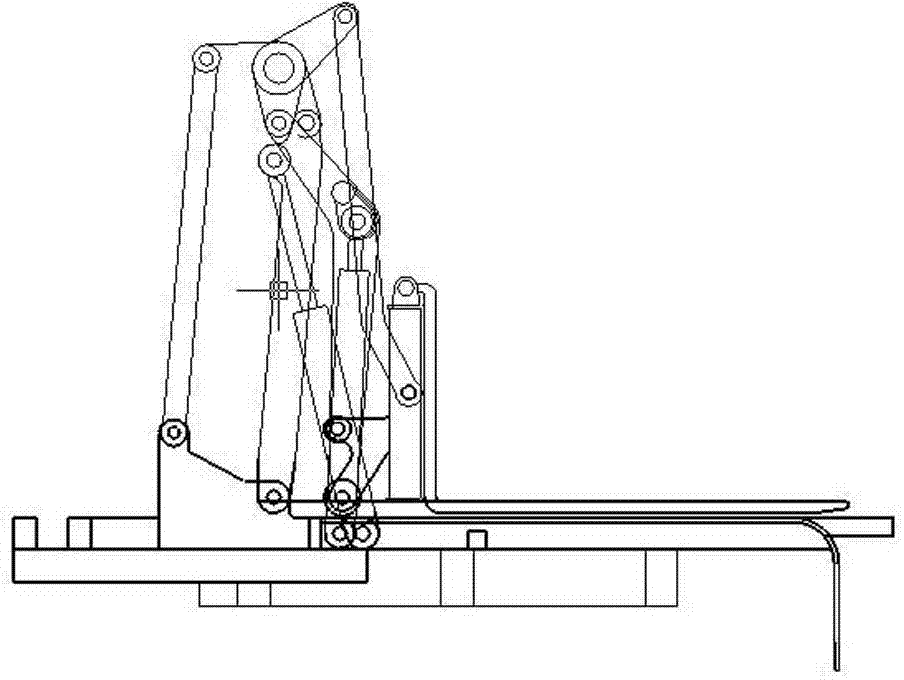

[0017] The invention comprises four components of an upper parallel four-bar mechanism, a lower parallel four-bar mechanism, a cargo fork mechanism and a vehicle frame.

[0018] Such as figure 1 , figure 2 As shown, the lower parallel four-bar mechanism includes two bases 15, two main arms 3, two main arm hydraulic cylinders 2, two lower rods 4, two outer torsion arms 5 and a connecting shaft 17 and other parts . Two bases 15 are respectively fixed on both sides of the vehicle frame 14, and a main arm 3, a pull down rod 4 and a main arm hydraulic cylinder 2 are respectively hinged on each base 15. An outer torsion arm 5 is respectively socketed and fixed at the two ends of the connecting shaft 17, one end of the outer torsion arm 5 is hinged with the upper end of the main arm 3 on the side, and the other end of the outer torsion arm 5 is connected to the pull-down rod 4 on the side. The upper end is hinged. The piston rod on each main arm hydraulic cylinder 2 is hinged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com