Original-position denitrification reactor in flowing water area

A reactor, denitrification technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution, short life, weak denitrification ability, etc. Achieve the effect of low maintenance cost, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

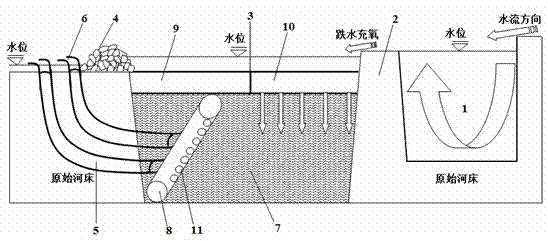

[0008] Further illustrate the present invention below in conjunction with accompanying drawing

[0009] refer to figure 1 The in-situ denitrification reactor for flowing waters of the present invention comprises a grit chamber 1, a drop dam 2, a reaction tank 3 and a water retaining wall 4 piled up with pebbles which are successively arranged on the river bed along the flow direction, and the lower layer of the reaction tank 3 is filled with Sawdust layer 7. A PVC pipe 8 for collecting denitrification tail water is laid at the bottom of the wood chip layer 7 near the cobblestone water retaining wall 4. The PVC pipe 8 has a plurality of tail water collection holes 11 with gauze, and the PVC pipe 8 The water outlet is connected to the soft underground drainage pipe 5, which passes through the bottom of the river bed below the cobblestone water retaining wall 4, and its water outlet is exposed on the surface of the river bed downstream of the cobblestone water retaining wall 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com