Manual grasping device for large-diameter tunnel segments

A tunnel segment and gripping device technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of large-diameter segment reversing, large working space requirements, and difficult maintenance, so as to reduce operation difficulty and labor Strength, the effect of improving the efficiency of bad luck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

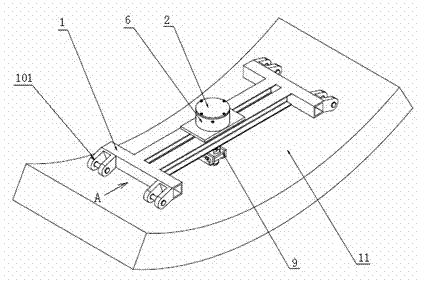

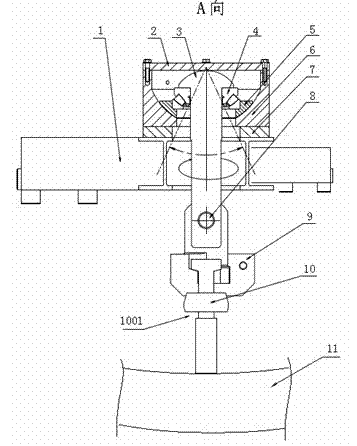

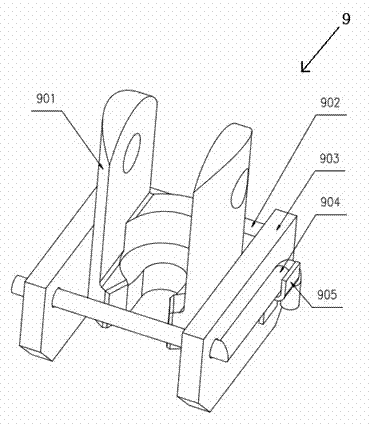

[0013] Such as figure 1 with figure 2 As shown, the large-diameter tunnel segment manual gripping device includes a bracket 1, a cover 2, a rotating shaft 3, a thrust self-aligning bearing 4, a spherical seat 5, a spherical support 6, a backing plate 7, a pin shaft 8, and a grabbing head 9 and the gripping bolt 10; the bracket 1 is an upper arched weldment, with four hook points 101 arranged symmetrically, and the grabbing head 9 is located at the center of the bracket 1; the grabbing head 9 is connected to the rotating shaft 3 through the pin shaft 8, The rotating shaft 3 is positioned by the self-aligning bearing 4, the spherical seat 5, and the spherical support 6. The spherical surface of the shaft end of the rotating shaft 3 withstands the cover 2 fixed by bolts. Due to the existence of the spherical seat 5 and the thrust self-aligning bearing 4, the rotating shaft 3 can rotate around The axis is free to rotate and the spherical surface around the spherical support 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com