Gas turbine support system

A gas turbine and support system technology, which is applied to gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of reduced reliability and service life of the support system, cracks, etc., so as to avoid cracks in the support arm, work stably and reliably, and improve the service life. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

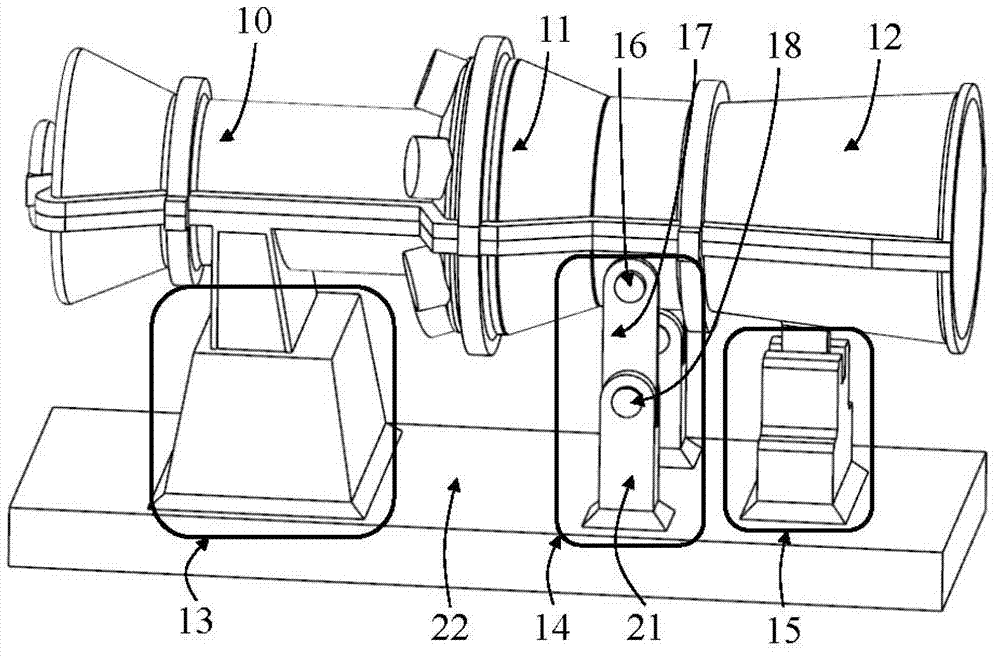

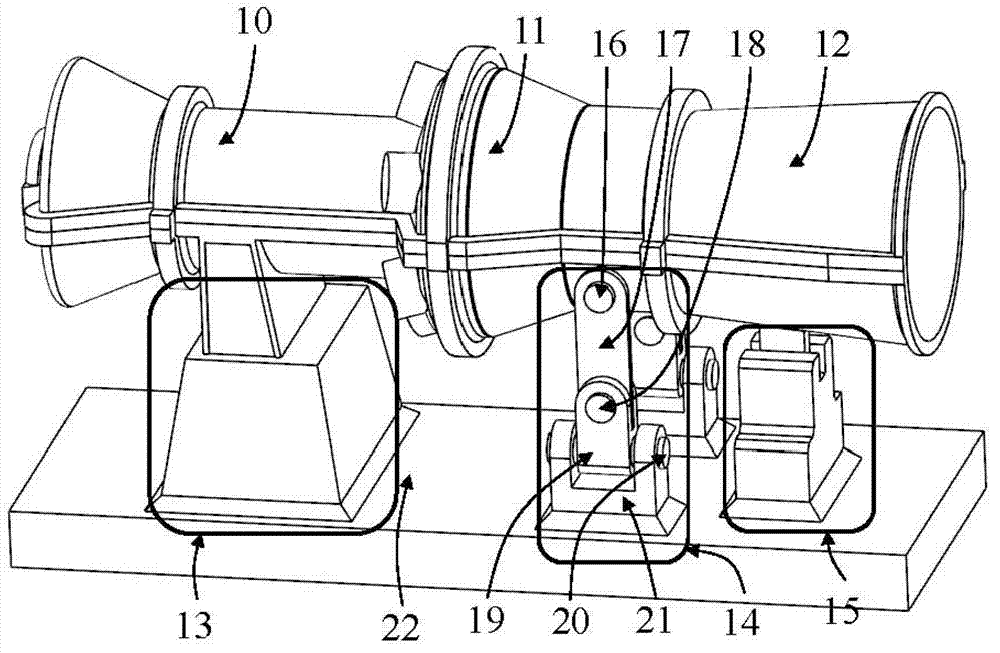

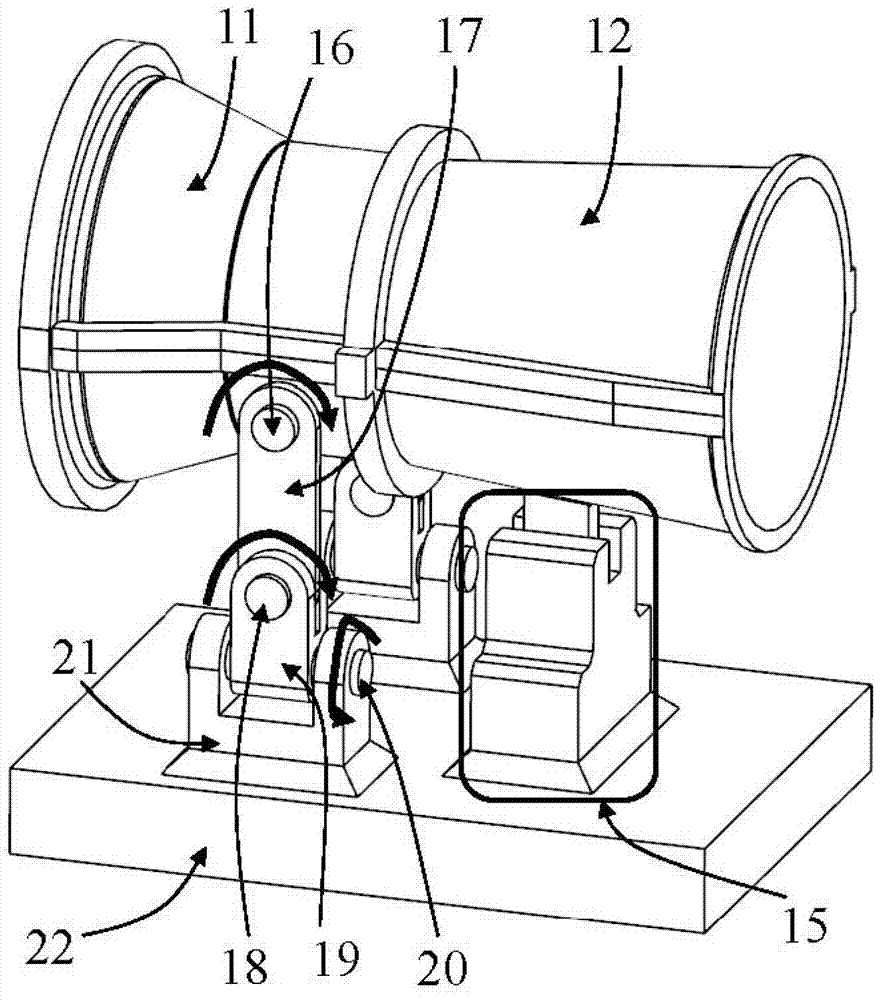

[0016] figure 1 It is a schematic diagram of the overall structure of an existing gas turbine, including two parts: the gas turbine body and the support system. The gas turbine body includes a compressor cylinder 10, a turbine cylinder 11, and an exhaust cylinder 12 from front to back; Cylinder support mechanism 14, exhaust cylinder guide rail mechanism 15 and base 22; compressor cylinder support mechanism 13 is connected with compressor cylinder 10 and base respectively, turbine cylinder support mechanism 14 is respectively connected with turbine cylinder 11 and base 22, exhaust cylinder guide rail mechanism 15 is connected with exhaust cylinder 12 and base respectively. The compressor cylinder support mechanism 13 is fixed on the base 22, which is the absolute dead point in the axial direction of the gas turbine. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com