Adjustable anchor device for fixing automobile production line equipment

An automobile production line, adjustable technology, applied in the direction of mechanical equipment, engine frame, supporting machine, etc., can solve the problem that the extension distance affects the standing position of the operator, it is difficult to ensure the accuracy of the equipment, and it does not conform to ergonomics. Remarkable application effect, compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided according to the present invention are described in detail as follows:

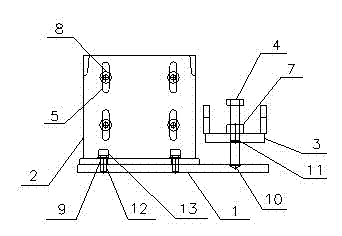

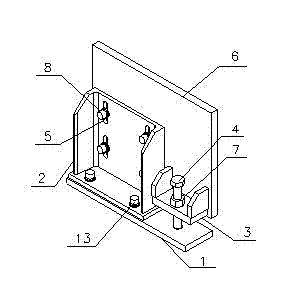

[0017] see figure 1 , figure 2 , an adjustable anchor device for fixing automobile production line equipment.

[0018] The anchor plate 1 is located at the bottom of the device, and the two sides of the upper surface of the anchor plate 1 are correspondingly provided with an anchor support seat 2 and an adjustment positioning bracket 3; the anchor support seat 2 includes a main body surface, a bottom surface and corresponding two sides, It forms a dustpan shape with an upward opening, and its bottom surface is connected with the threaded hole 12 provided on the anchor plate 1 through the through hole 9 provided on the anchor support seat 2 with screws 13, so that the relative positions of the two are fixed; The main body surface of the foot support seat 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com