Measurement and control system with discriminative tracking for temperature of high-temperature resistance furnace and monitoring method thereof

A high-temperature resistance furnace, measurement and control system technology, applied in furnace control devices, furnaces, furnace components, etc., can solve the problem that the heating rate and power output in the middle and low temperature sections cannot be accurately controlled in real time, and affect the effective implementation of heat treatment production processes. Control system The problem of high hardware cost can eliminate sudden jumps and discontinuities, improve temperature control coordination and synchronization, and improve accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

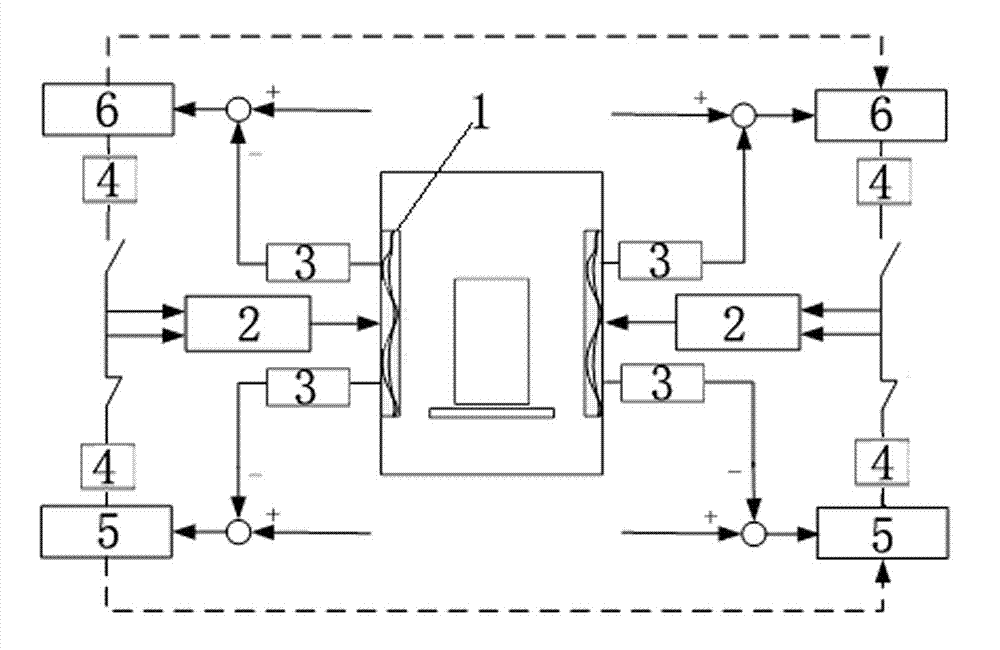

Embodiment 1

[0021] The invention includes dividing the high-temperature resistance furnace into two heating zones symmetrically and uniformly, each heating zone is provided with a resistance heating element 1, and each heating zone is provided with a heating power supply main circuit unit 2, a high and low temperature difference measurement variable Sending unit 3, high and low temperature control circuit unit 4; heating power supply main circuit unit 2 includes heating power supply, low-voltage switch protection electrical appliances, and power regulator, and the heating power supply is connected to the resistance heating body 1 in the heating zone through the power regulator; high and low temperature distinction The measurement transmission unit 3 includes a high temperature thermometer and a movable thermocouple, both of which are arranged in the heating zone, the high temperature thermometer is connected to the high temperature control instrument 6, and the movable thermocouple is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap