Prediction method for complete machine performance decline trend of aeroengine

An aero-engine and trend forecasting technology, which is applied in engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of no aero-engine overall life prediction and evaluation, no performance data on aero-engine performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

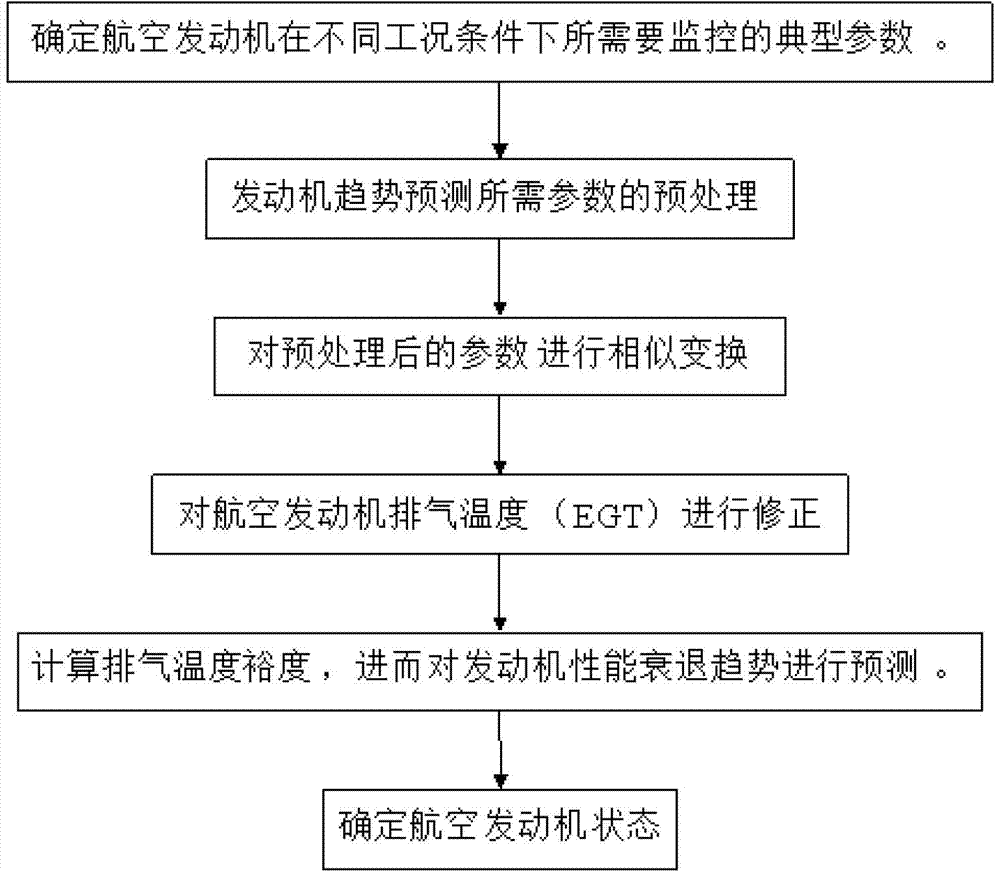

[0027] Such as figure 1 Shown, the present invention comprises the following steps:

[0028] Step 1 is to determine the typical parameters that need to be monitored by the aero-engine under different working conditions.

[0029] First of all, the parameters to be monitored should be selected. The monitored parameters should accurately reflect the health status of the engine performance, and the change trend of the monitored parameters can correspond to the relevant engine failure symptoms.

[0030] The main gas path monitoring parameters of aero-engine status monitoring are:

[0031] The fan speed N1 is the fan speed of the turbofan aeroengine. Most of the thrust of a high bypass ratio turbofan engine is generated by the bypass airflow, so the fan speed N1 is generally used to represent the thrust of the turbofan engine in engineering applications an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com