Raw coal sample making method

A production method and technology of coal samples, applied in the field of production of coal samples used in indoor experiments, can solve the problems of sampling failure, uneven force on coal blocks, easy eccentricity, etc., and achieve the effect of increasing stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

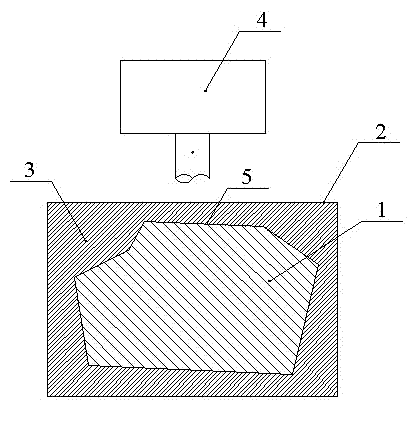

[0012] Depend on figure 1 The raw coal coal sample production method shown is characterized in that it includes the following steps: (1) first seal the raw coal block 1 taken back from the coal mine site with a packaging film 5, and then place it in a box body 2 of an appropriate size. The body 2 is a wooden box, and the packaging film 5 is a plastic film. It should be ensured that there are no air bubbles in the packaging film 5, and then the fine aggregate concrete 3 is poured to make the concrete 3 fill all the gaps between the packaging film 5 and the box body 2, so that , the concrete 3 is densely wrapped on the top, bottom and circumference of the packaging film 5, and the original coal block 1 is wrapped in the packaging film 5, that is, the concrete 3 fills all the gaps between the original coal block 1 and the box body 2, (2) curing After 1 to 2 days, after the concrete 3 is completely hardened, the box body 2 can be placed on the coring platform of the drilling sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com