Manufacturing method of inclusion standard sample synthesized by fused silica capillary

A technology of fused silica and capillary, which is applied in the field of preparation of fluid inclusion standard samples, to achieve the effects of operation difficulty and equipment cost reduction, regular products and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation method of pure liquid fused silica capillary inclusion

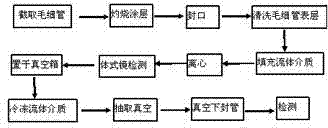

[0028] combine figure 1 As shown, it is a method of making a pure liquid fused silica capillary inclusion standard sample, that is, a pure liquid is wrapped with quartz to form a fluid inclusion standard sample. Taking water as the fluid as an example, the steps are as follows:

[0029] (1) Intercept capillary: intercept each section of quartz capillary with a length of about 50 mm, and select fused silica capillary for gas chromatography column; the intercepted capillary is in pairs, and the two lengths of each pair of capillary should be equal; for the convenience of centrifugation The centrifuge does not deflect;

[0030] (2) Burning coating: the coating on the outer surface of the capillary about 35mm away from one end of the fused silica capillary, burn the coating with the outer flame of the hydrogen flame gun to remove the coating and increase the transparency of the capillar...

Embodiment 2

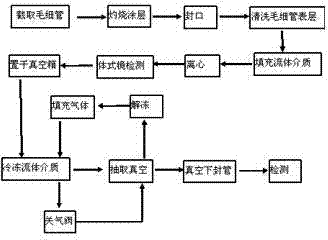

[0043] Such as figure 2 Shown is a preparation method of a liquid-gas fused silica capillary inclusion standard sample in which a gas-liquid two-phase fluid is encapsulated in a quartz capillary. The liquid is water and the gas is carbon dioxide as an example for illustration.

[0044] Among them, the steps ( 1)-(8) The operations of intercepting the capillary, burning the coating, sealing, cleaning the surface of the capillary, filling the fluid medium, centrifuging, stereoscopic mirror detection and vacuum extraction are the same as those in Example 1, the only difference is that the gas filling operation is added , the operation is as follows:

[0045] (9) Freezing fluid medium: cooling the liquid water in the capillary to condense into solid ice;

[0046](10) Vacuuming again: control the vacuum valve to vacuumize again, and keep it until the end of sealing;

[0047] (11) Thawing: close the vacuum valve, lower the lifting table, and let the sealed end of the fused silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com