Liquid-to-metal corrosion testing device

A corrosion test and test device technology, applied in the direction of removing certain components and weighing, can solve the problem of no metal corrosion test test device, etc., and achieve the effect of stable operation and accurate control of temperature and liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

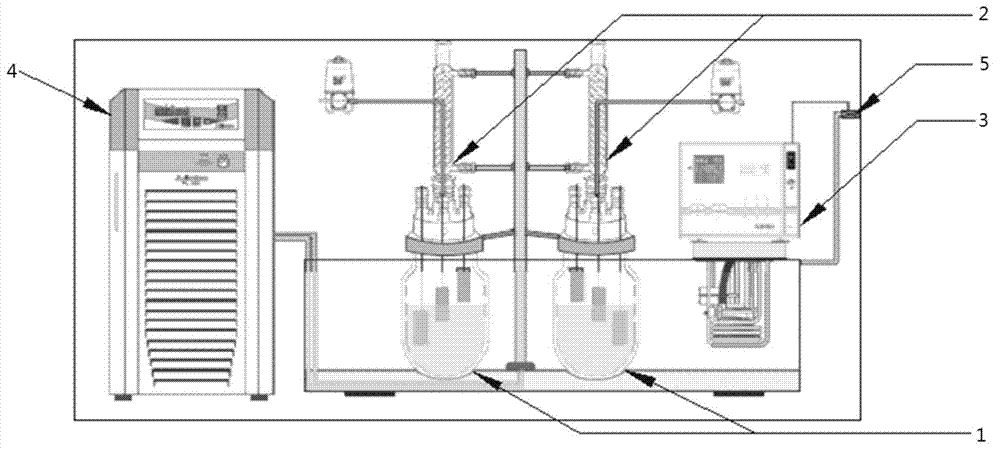

[0014] Such as figure 1 As shown, the metal corrosion test device of the present invention includes two fully transparent scaled corrosion container kettles 1, two sets of serpentine condenser tubes 2, a constant temperature water bath 3, a circulating cooling water bath 4, and fully automatic liquid level control The device, analytical balance and iron stand, can carry out two sets of tests at the same time. Among them, the fully transparent scale corrosion container kettle, the serpentine condenser are custom-made, the constant temperature water bath, the circulating cooling water bath, the automatic liquid level control device, and the analytical balance is outsourced.

[0015] Two fully transparent scale corrosion container kettles 1 are placed in the constant temperature water bath 3 and fixed on the iron stand, and the two serpentine condenser tubes 2 are also fixed on the iron stand and connected to the two container kettles 1 respectively. The water inlet and outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com