Metallography detection method for bonding interface having honeycomb sandwich structure

A honeycomb interlayer and metallographic detection technology, applied in the field of measurement, can solve the problems of complex structure and shape, inability to determine the factors affecting the bonding quality, and inability to detect weak adhesion and virtual adhesion of the honeycomb structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

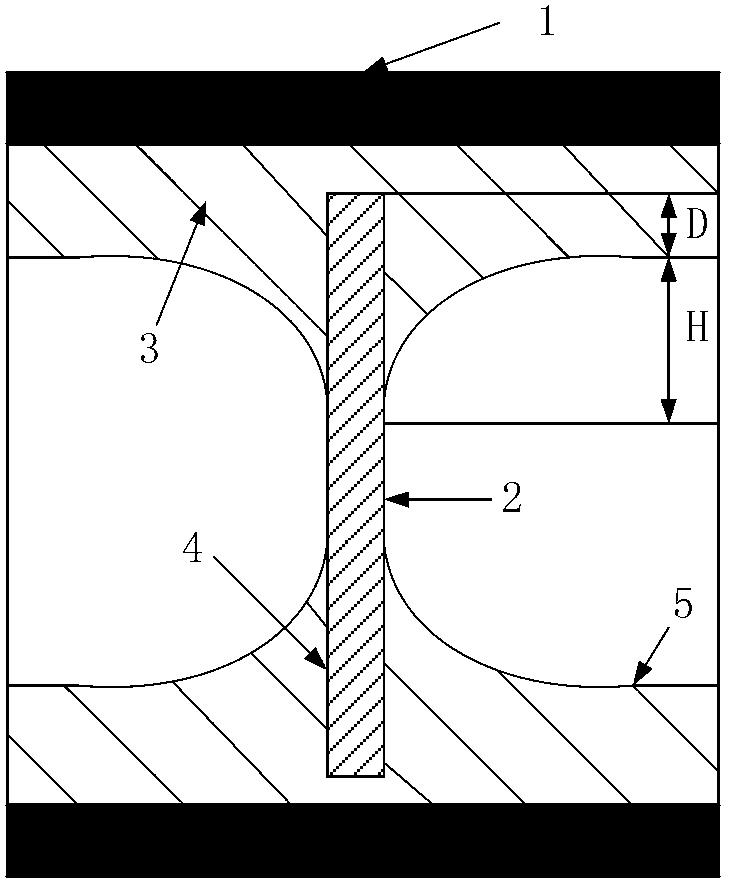

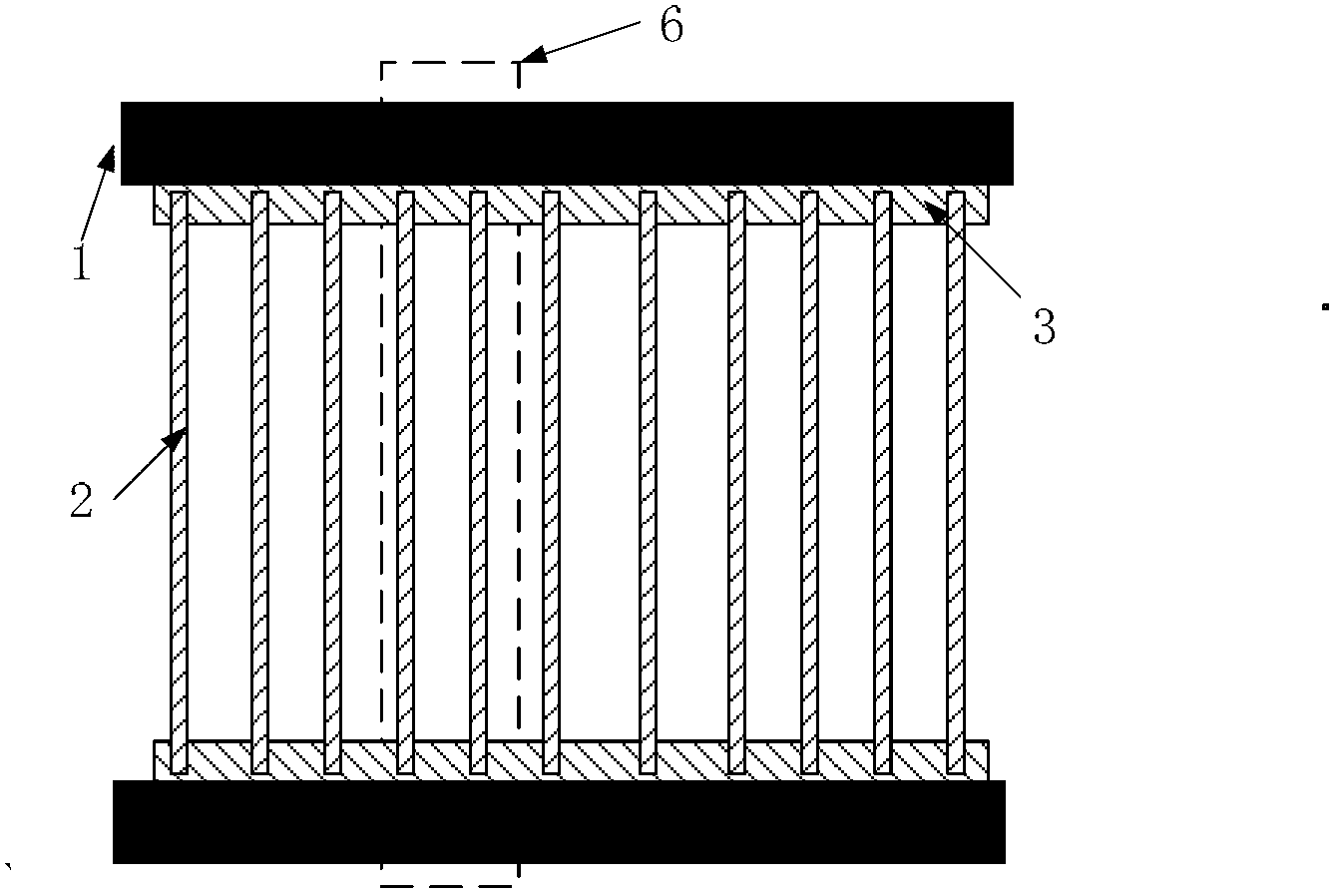

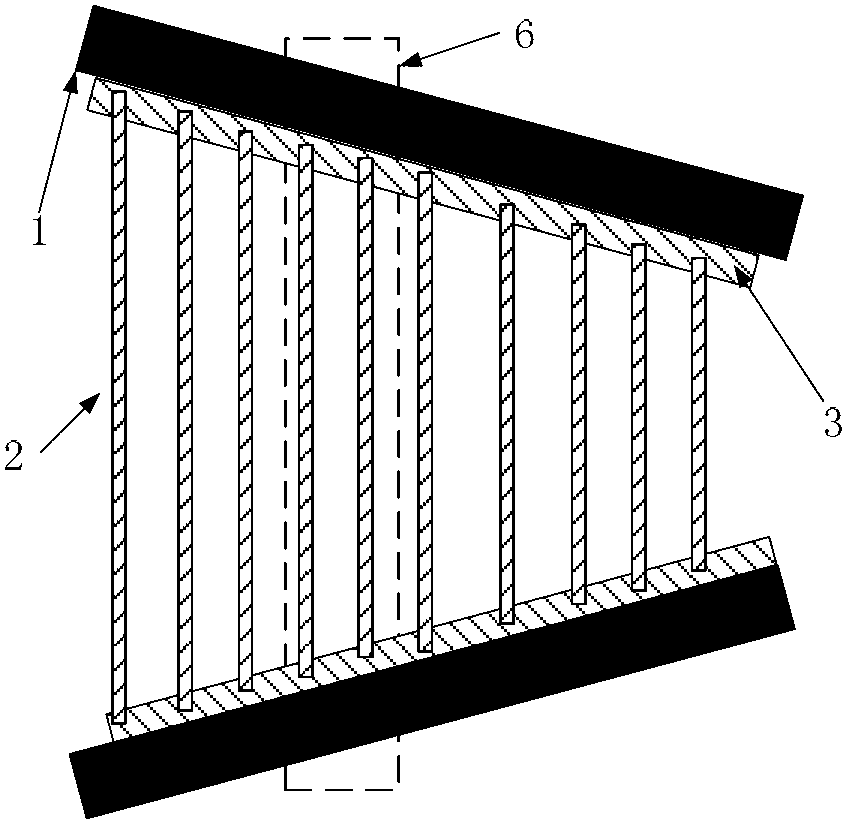

[0029] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0030] See attached Figure 1~6 Shown, the metallographic detection method of the bonding interface of a kind of honeycomb sandwich structure is characterized in that: the step of this method is:

[0031] (1) Cut sample 6 on the honeycomb sandwich structure. Sample 6 is cut in a direction perpendicular to skin 1, that is, parallel to honeycomb wall 2. The position and quantity of sample 6 should meet the following conditions:

[0032] 1.1 For a flat honeycomb sandwich structure with no change in thickness and dimension, at least two samples 6 shall be cut from the middle and the edge respectively;

[0033] 1.2 For the honeycomb sandwich structure with varying thickness and dimension, cut at least two samples 6 at the maximum and minimum places of the thickness test;

[0034] 1.3 For the honeycomb sandwich structure with var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com