Lifting electrical motor for electrical forklift

An electric forklift and electric motor technology, which is applied to asynchronous induction motors, electric components, electrical components, etc., can solve the problems of easy damage to the commutation device, poor reliability of the motor, difficult after-sales maintenance, etc., and achieves low noise, good heat dissipation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

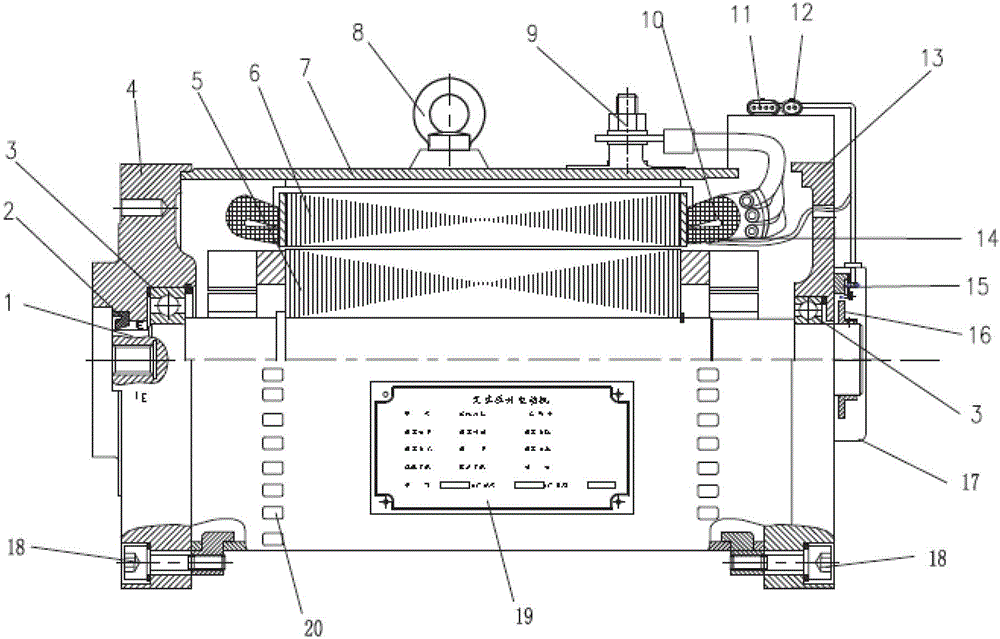

[0032] see figure 1 , The lifting motor for electric forklift in this embodiment includes an inner spline shaft 1, an oil seal 2, a bearing 3, a front end cover 4, a cast aluminum rotor 5, a stator core 6, a frame 7, an eyebolt screw 8, and a three-phase power terminal 9. Winding 10, speed sensor connection terminal 11, temperature sensor connection terminal 12, rear end cover 13, temperature sensor 14, speed sensor stationary part 15, speed sensor rotating part 16, sensor cover 17, hexagon socket bolt 18, nameplate 19.

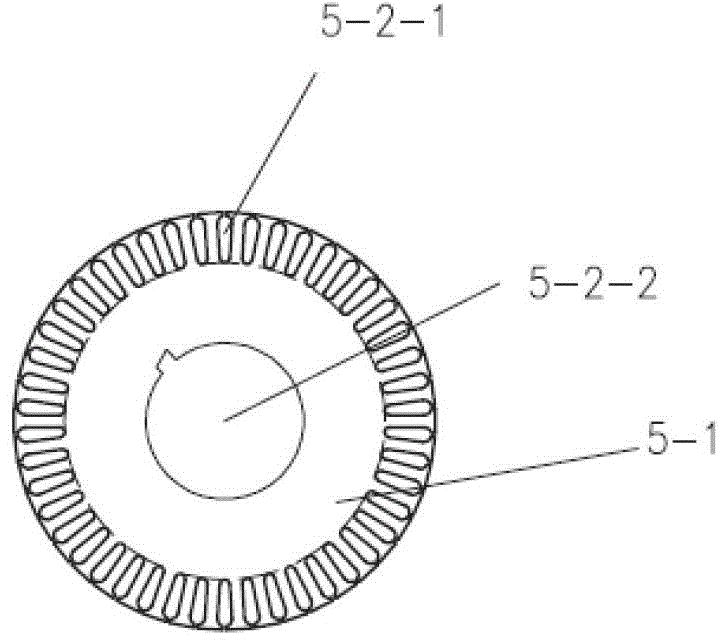

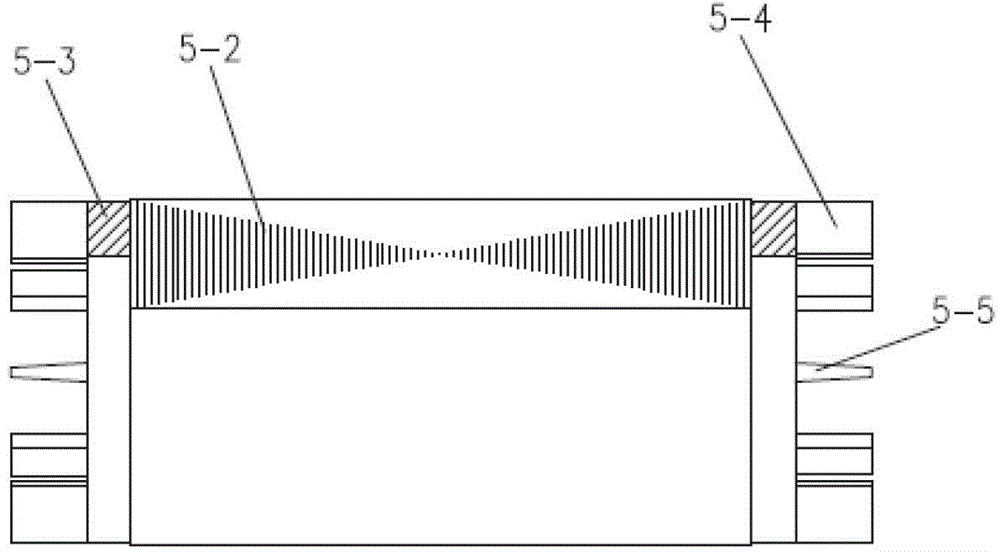

[0033] The cast aluminum rotor 5 is overlaid on the inner spline shaft 1 after being heated, and torque is transmitted between the two through interference fit. The cast aluminum rotor 5 and the inner spline shaft 1 constitute the rotor assembly of the motor. The front and rear ends of the inner spline shaft 1 are rotated and matched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com