Small-size integrated parallel rotation ultrasonic motor

An ultrasonic motor, an integrated technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of unsatisfactory parallel connection efficiency of multiple linear ultrasonic motors, In-depth, insufficient system and other problems, to achieve the effect of compact structure, high output efficiency, and excellent parallel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

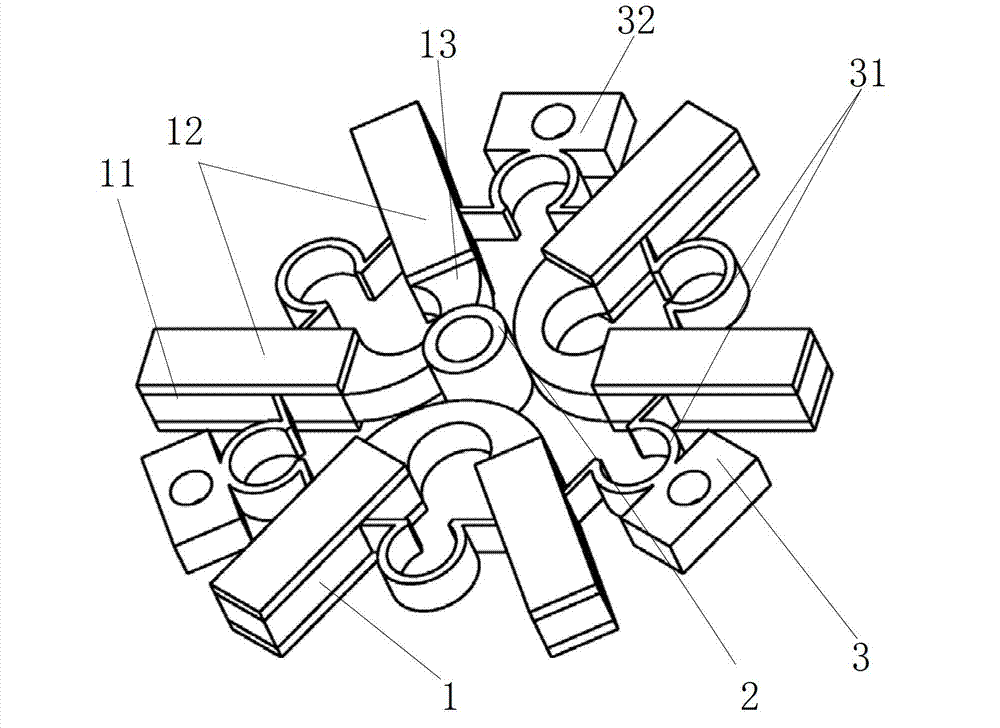

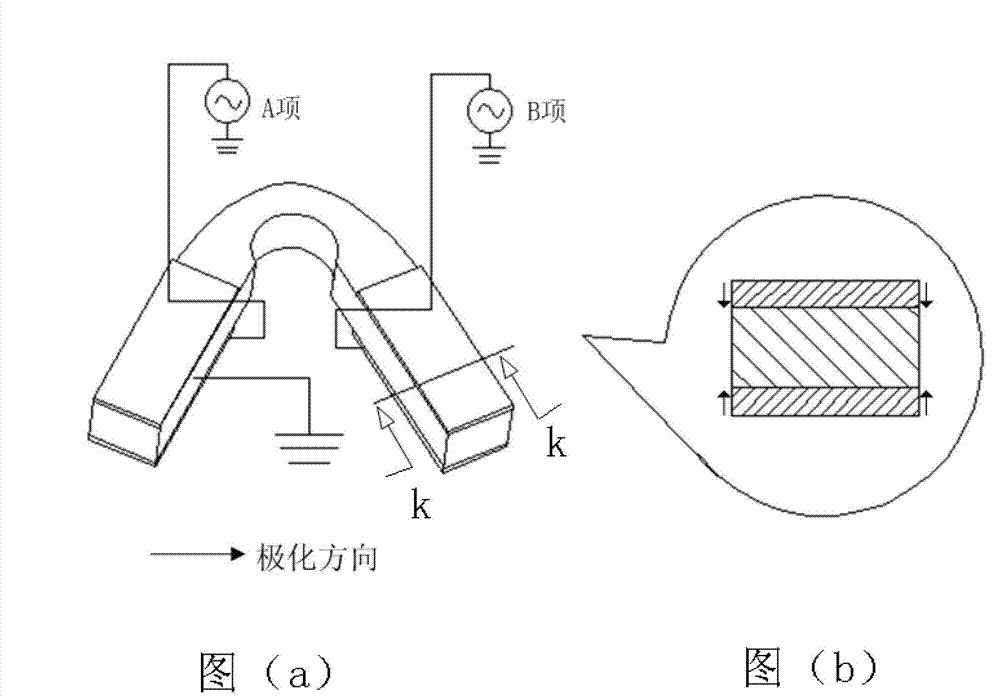

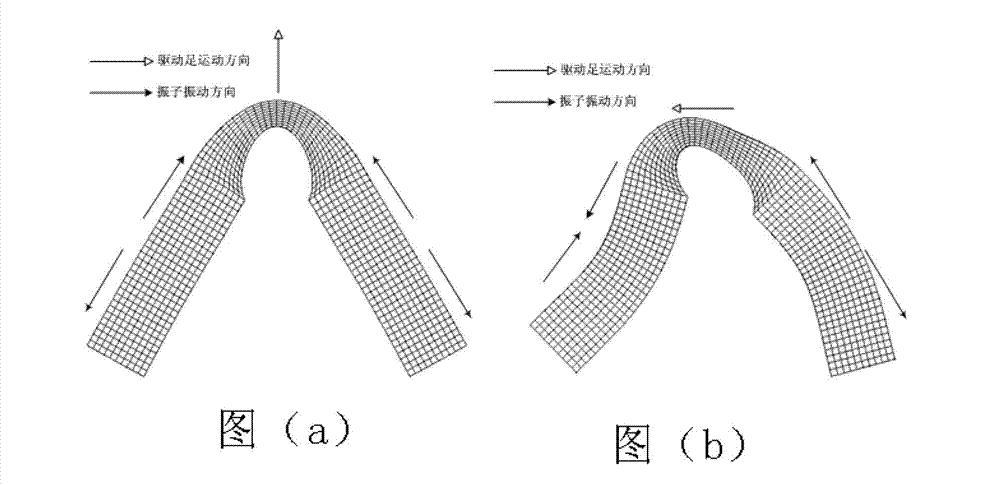

[0022] A small integrated parallel rotating ultrasonic motor of this embodiment is as Figure 1-3 As shown, it includes a stator 1 and a mover 2 as a bearing. The stator is composed of NN≥3 composite vibrators connected in parallel. The composite vibrators are connected through a flexible supporting element 3, and the composite vibrators are symmetrical around the mover 2 in the circumferential direction. place. Therefore, the force of the N composite vibrators on the mover is naturally balanced, and the entire stator can be processed in an integrated manner by wire cutting to ensure that the clamping of each composite vibrator is achieved without disturbing its vibration modal frequency, and the stator can also be made to move. The sub has a certain pre-pressure. Each composite vibrator is composed of two Langevin vibrators crossing each other at a certain angle, and the intersection angle of the two Langevin vibrators of each composite vibrator is between 0°-180°; The head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com