Dispensing nozzle for automatic analyzer, automatic analyzer equipped with the nozzle, and method for producing dispensing nozzle for automatic analyzer

An automatic analysis device and dispensing nozzle technology, applied in the direction of analysis materials, instruments, etc., can solve problems such as increased environmental load, large amount of waste, and difficulty in forming fine structures, so as to reduce operating costs, achieve microquantification, and improve cleaning. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0048] (device configuration)

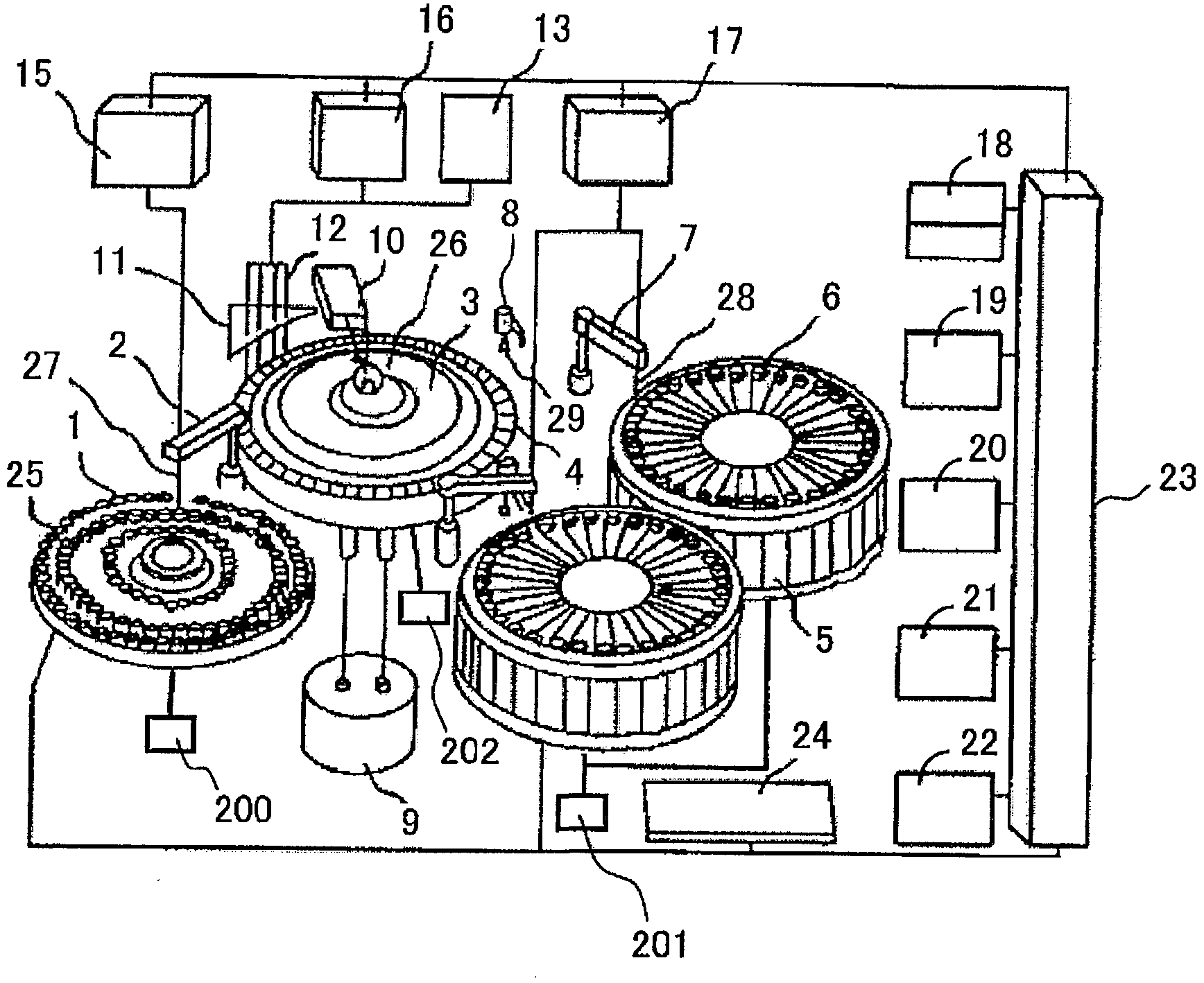

[0049] figure 1 A configuration example of the automatic analyzer according to the present invention is shown. The sample storage unit mechanism 1 is arranged in the automatic analyzer. One or more sample containers 25 are arranged in the sample storage unit mechanism 1 . figure 1 The illustrated sample storage unit mechanism 1 is an example of a so-called sample tray mechanism in which a sample container 25 is detachably mounted on a tray-shaped main body. In fact, other mechanisms such as sample racks or sample holders that are generally used in automatic analyzers may be used in the sample storage unit mechanism 1 .

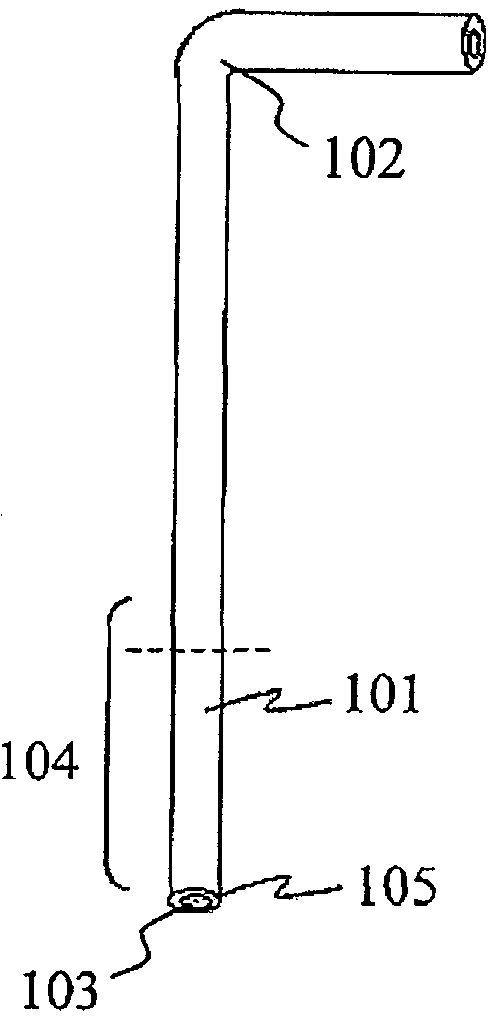

[0050] The sample referred to here refers to the test solution used for the reaction in the reaction container, and may be a collected sample stock solution, or may be a solution processed by dilution, pretreatment, etc. of the stock solution. The sample in the sample container 25 is extracted by the sample dispensing nozzle...

experiment example 1)

[0084] First, in order to improve the reliability of the analysis, the effect was verified using a flat substrate. The size of the substrate used was 30 mm x 30 mm x 0.5 mm, and the measurement surface used for effect verification was a surface of 30 mm x 30 mm.

[0085] Figure 5 Indicates the flow of the surface treatment process.

[0086] Process 1. Cleaning of stainless steel

[0087] The SUS304 substrate was ultrasonically cleaned with 0.1% NaOH aqueous solution and ethanol for 15 minutes, and washed with water. After that, the SUS304 substrate was dried by blowing nitrogen.

[0088] Step 2. Immersing in a solution of a phosphonic acid derivative

[0089] The SUS304 substrate cleaned in step 1 was immersed in the solution of the phosphonic acid derivative for 24 hours. Thereafter, it was taken out from the solution, and after washing with a solvent, it was washed with pure water. After that, the SUS304 substrate was dried by blowing nitrogen.

[0090] The validation ...

experiment example 2)

[0092] In the case of the aforementioned Experimental Example 1, the surface treatment was performed by a procedure of adsorbing a phosphonic acid derivative in a one-stage reaction. In the case of Experimental Example 2, a method of surface treatment by a multi-step reaction will be described.

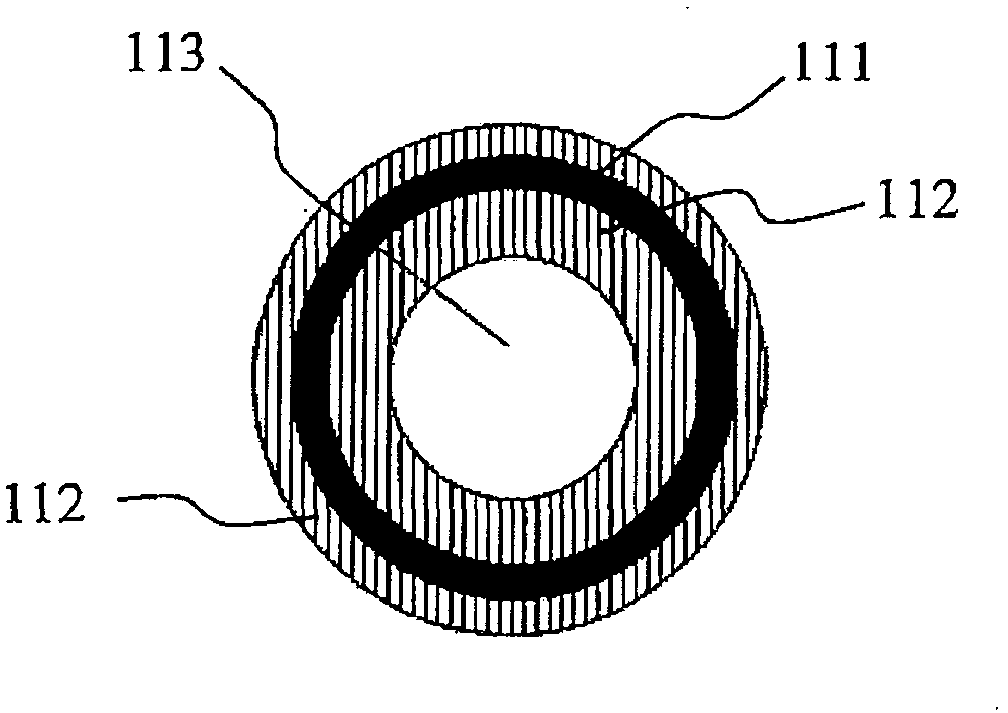

[0093] Figure 7 Indicates the flow of the surface treatment process. This surface treatment step is roughly composed of two treatment steps. The first is a step of coating the surface of stainless steel with a phosphonic acid derivative having a reactive functional group at the end, and the second is a step of immobilizing a molecule having a desired function to the reactive functional group.

[0094] In the case of this experimental example, first, a method of first immobilizing a phosphonic acid having a carboxyl group at the end on the nozzle surface, and then reacting and activating the carboxyl group will be described. In addition, polyethylene glycol (PEG) derivatives were u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com