Disc brake capable of detecting abrasion losses of break lining block

A technology of disc brakes and brake pads, which is applied in the direction of brake types, axial brakes, mechanical equipment, etc., can solve the problems of no indication of brake pad wear warning indicators and continuous wear sensors, etc., and achieve simple structure , easy to use, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

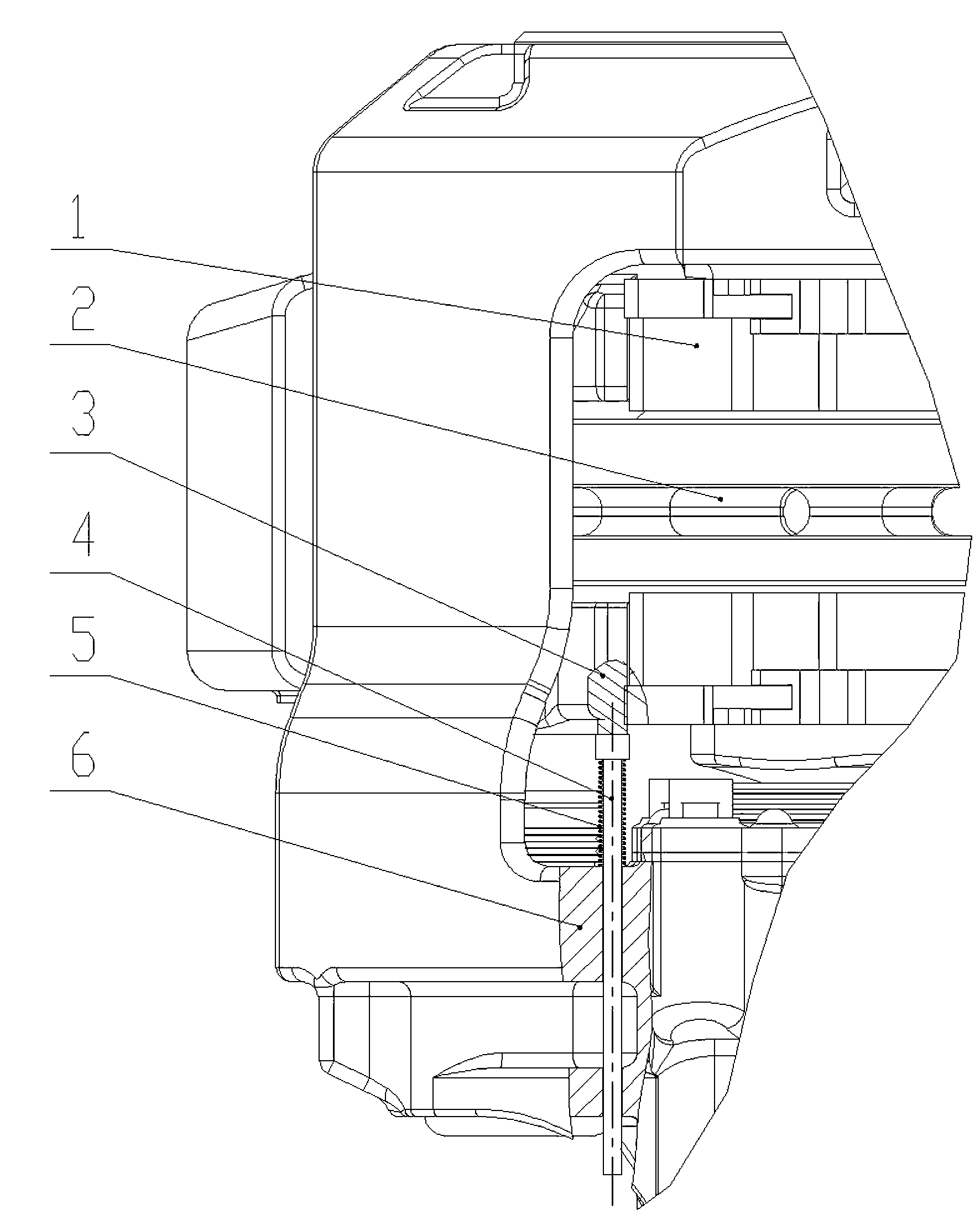

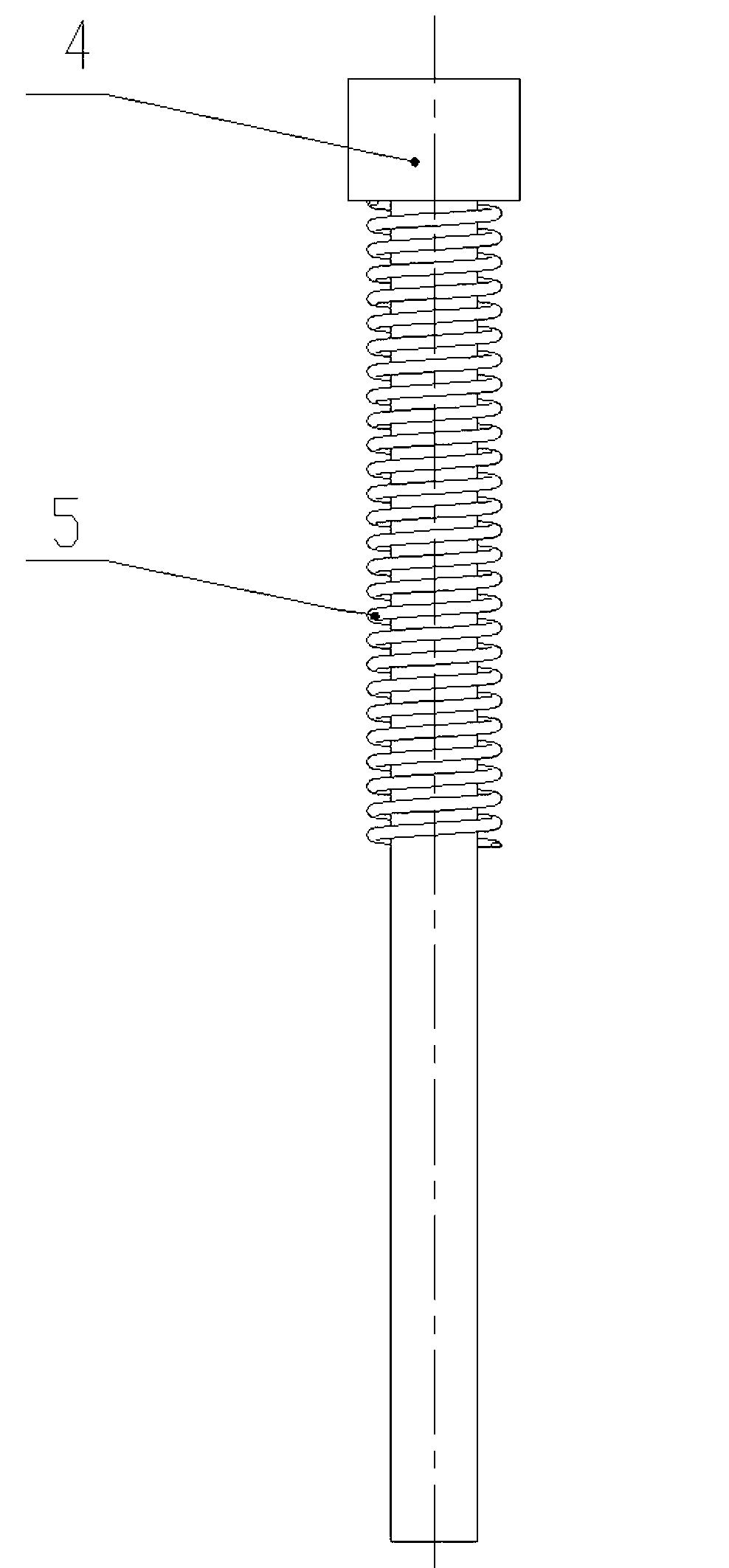

[0014] Such as figure 1 and figure 2 A specific embodiment is shown, which is an improvement of the existing disc brake. The existing disc brake includes a caliper body 6, a bracket 3, a brake disc 1 and a brake pad 2, and the caliper body 6 is slidably set On the bracket 3, a brake gap automatic adjustment mechanism is connected between the caliper body 6 and the bracket 3. When the brake pad 2 or the brake disc 1 starts to wear, the brake gap automatic adjustment mechanism makes the caliper body 6 relative to the bracket 3. Sliding, keeping the gap between the brake pad 2 and the brake disc 1 constant. This patent adds a detection body 4 on the basis of the aforementioned prior art. The length direction of the detection body 4 is in the same direction as the axial direction of the brake disc 1. One end of the detection body 4 is kept on the bracket 3, and the detection body 4 can be directly It is fixed on the support 3, and one end of the detection body 4 can also be kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com