Installation device and method for arc-second-level three-dimensional optical deformation measurement device

A technology of three-dimensional optics and measuring devices, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of the decrease of deformation measurement accuracy, the difficulty of achieving temperature stability and structural stability, and the lack of special precision installation devices and methods for each component, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

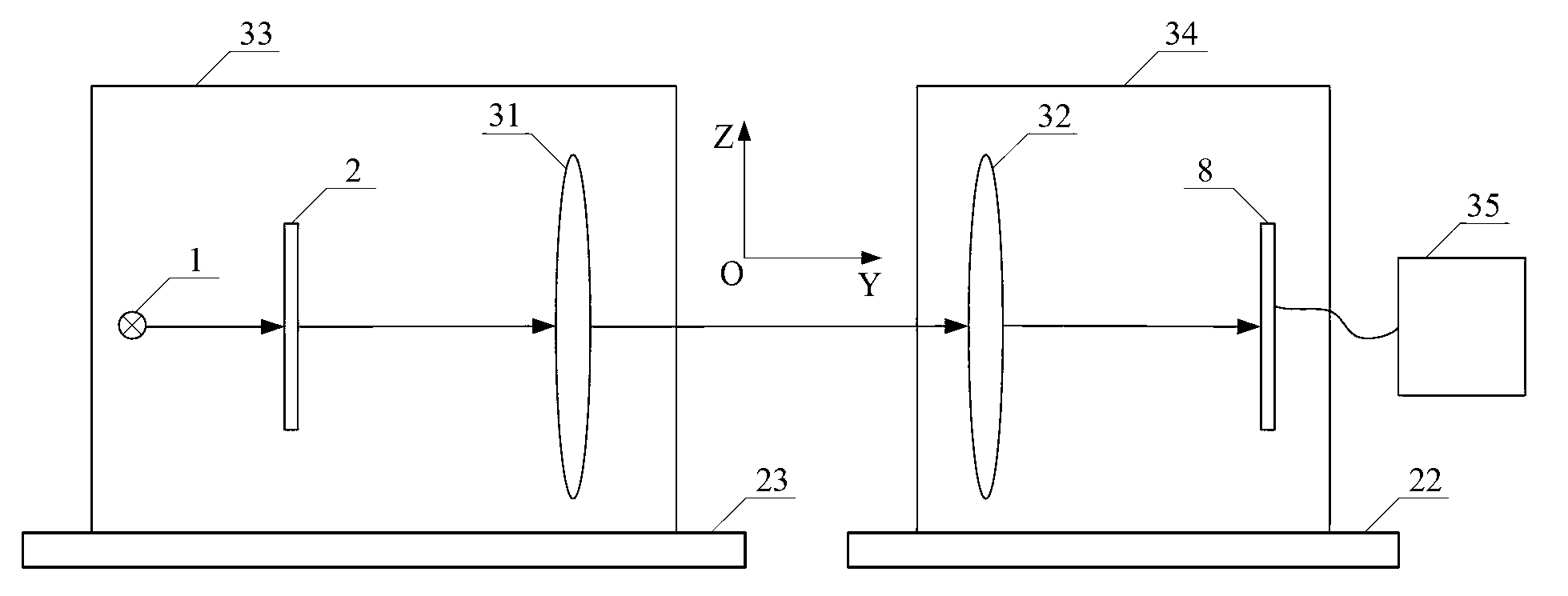

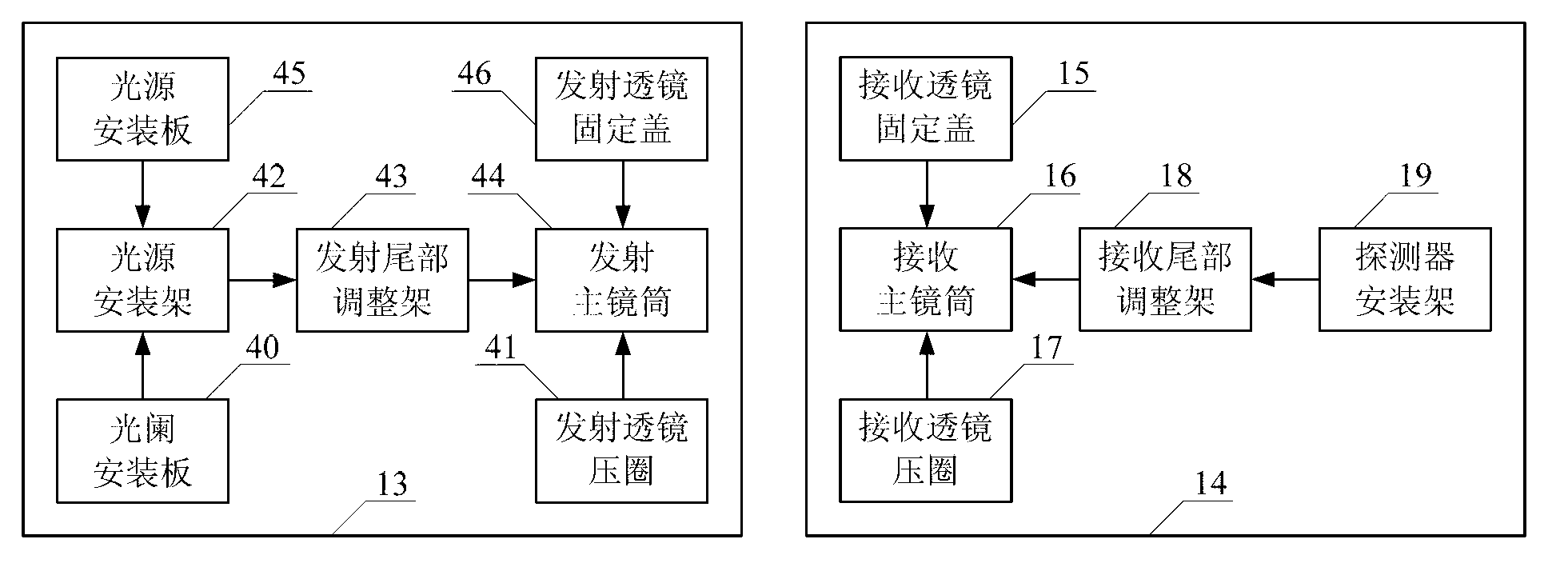

[0082] figure 2 It is the overall structure diagram of the installation device of the present invention. The mounting device proposed by the present invention is composed of a transmitting module mounting device 13 and a receiving module mounting device 14 . The light source 1, diaphragm 2 and emission optical system 31 of the three-dimensional optical deformation measuring device are installed inside the transmitting module installation device 13, and the receiving optical system 32 and the area array detector 8 of the three-dimensional optical deformation measuring device are installed inside the receiving module installation device 14 .

[0083] The transmitting module installation device 13 is composed of the transmitting main lens barrel 44 , the transmitting lens pressure ring 41 , the transmitting lens fixing cover 46 , the transmitting tail adjusting frame 43 , the light source mounting frame 42 , the light source mounting plate 45 and the aperture mounting plate 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com