Lining type device with ultrasonic flowmeter or ultrasonic thermal energy meter

An ultrasonic and flowmeter technology, applied in the field of flow measurement, can solve the problems of complicated installation, difficult installation, large volume, etc., and achieve the effect of low transportation cost, no economic loss, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

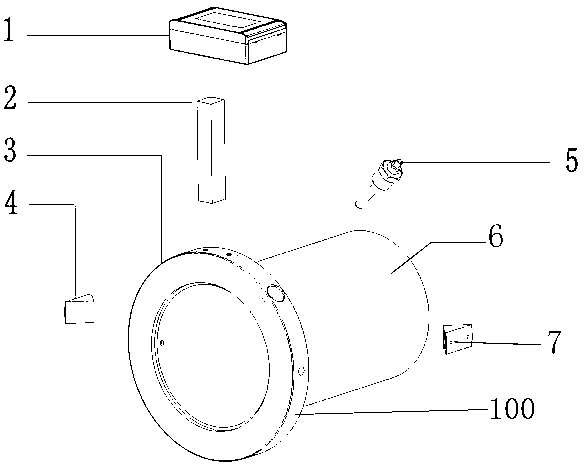

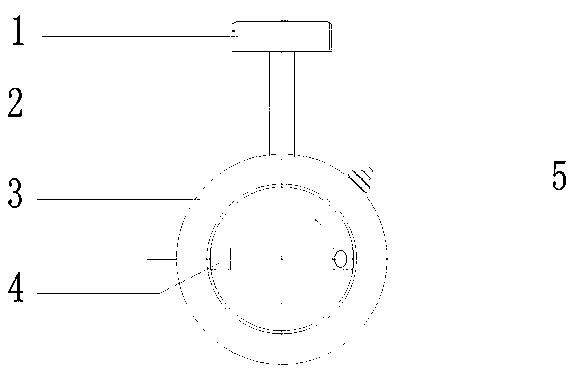

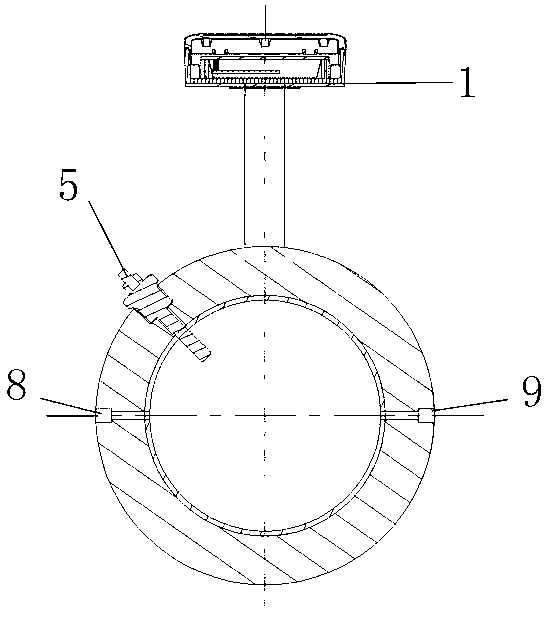

[0023] Numbers in the figure indicate: 1. Host; 2. Connection block; 3. Plywood; 4. First probe; 5. Probe; 6. Plywood support; 7. Second probe; 8. First stud; 9. The second stud; 10, the annular sealing groove of the flange; 11, the splint support of the strip structure; 20, the second pipeline; 30, the flange of the second pipeline; 40, the flange of the first pipeline; 50, The first pipeline; 60, the first waterproof gasket; 70, the second waterproof gasket; 100, the bushing type pipe section.

[0024] like figure 1 , figure 2 , image 3 , Figure 5 As shown, the present invention provides a bushing device with an ultrasonic flowmeter or an ultrasonic heat meter, the bushing device includes a bushing pipe section 100, and the bushing pipe section 100 is inserted into a pipeline for measuring liquid in a bushing manner The bushing pipe s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com