Bonding apparatus and method for controlling same

A bonding device and a technology of controlling the amount, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of reduced visibility of the display surface, etc., and achieve high-speed and efficient bonding, efficient positioning and bonding, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Below, embodiments of the present invention (hereinafter referred to as embodiments) will be specifically described with reference to the drawings.

[0087] [A. Composition]

[0088] [1. Overall composition]

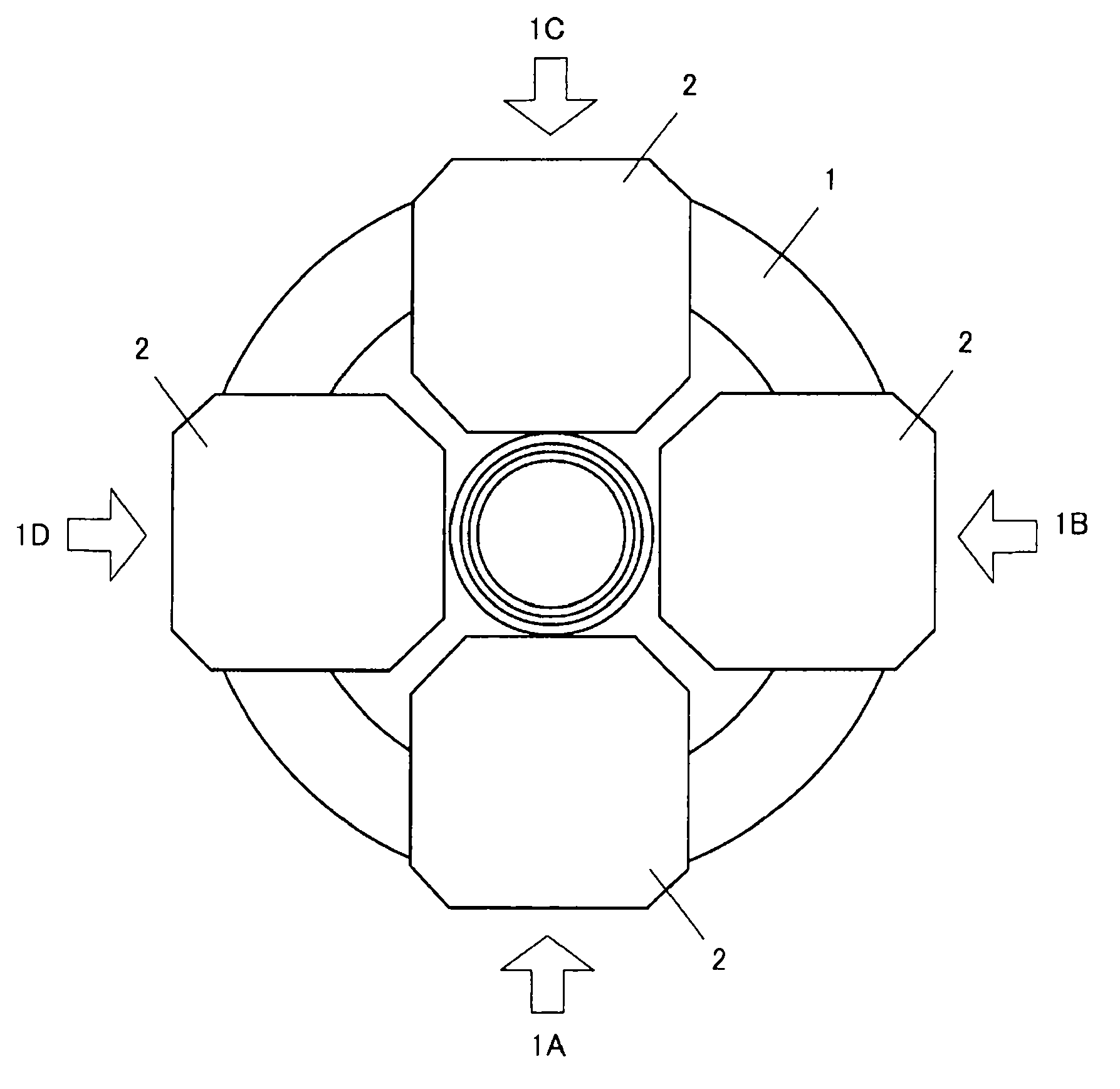

[0089] First, the whole structure of the bonding apparatus (henceforth this apparatus) of this embodiment is demonstrated. Such as figure 1 As shown, this device is a device in which four holding devices 2 are mounted on a rotary table 1 . The rotary table 1 is configured to be intermittently rotated by the index mechanism 11 corresponding to the loading and unloading position 1A, the sticking material preparation position 1B, the positioning position 1C, and the vacuum bonding position 1D.

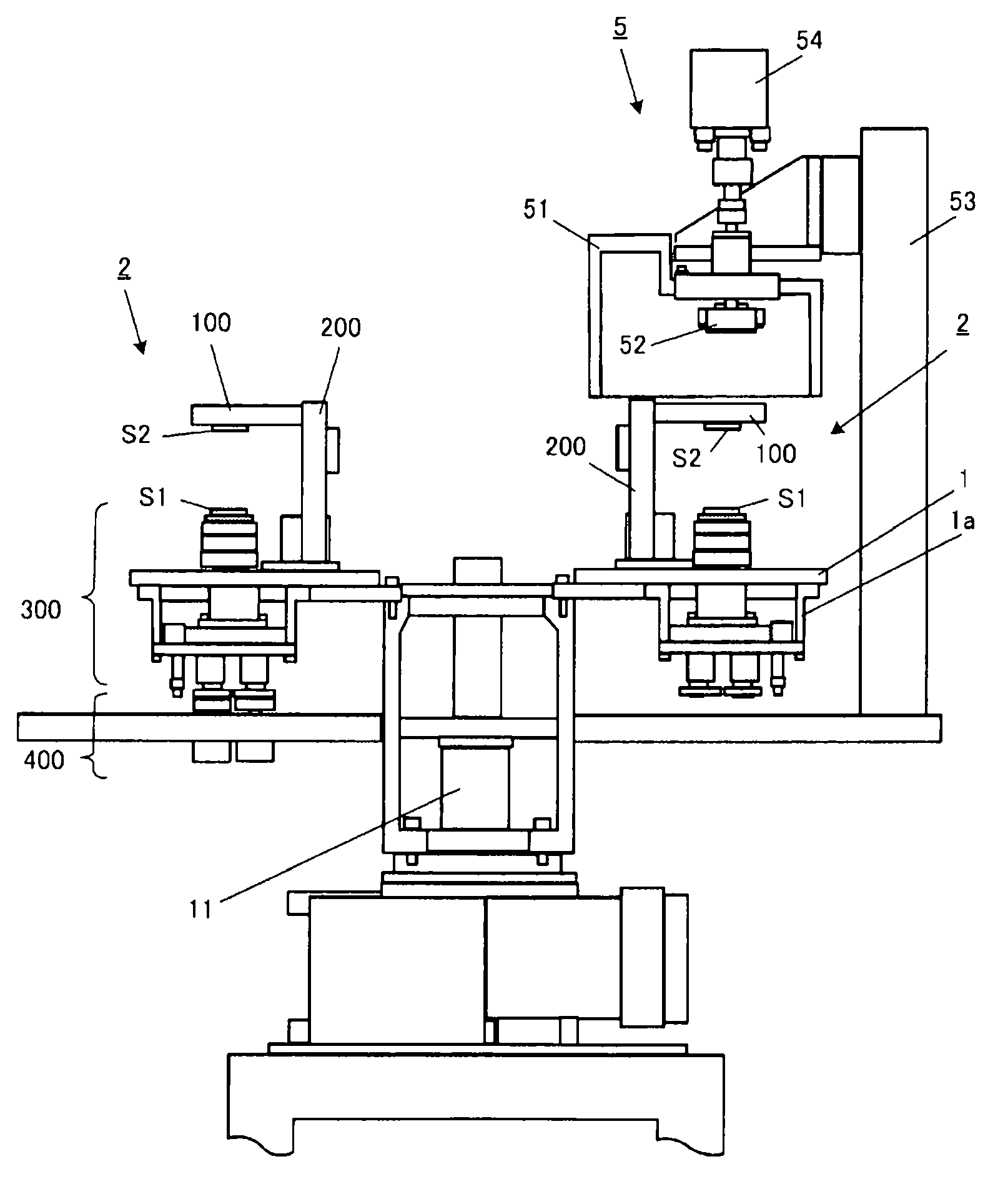

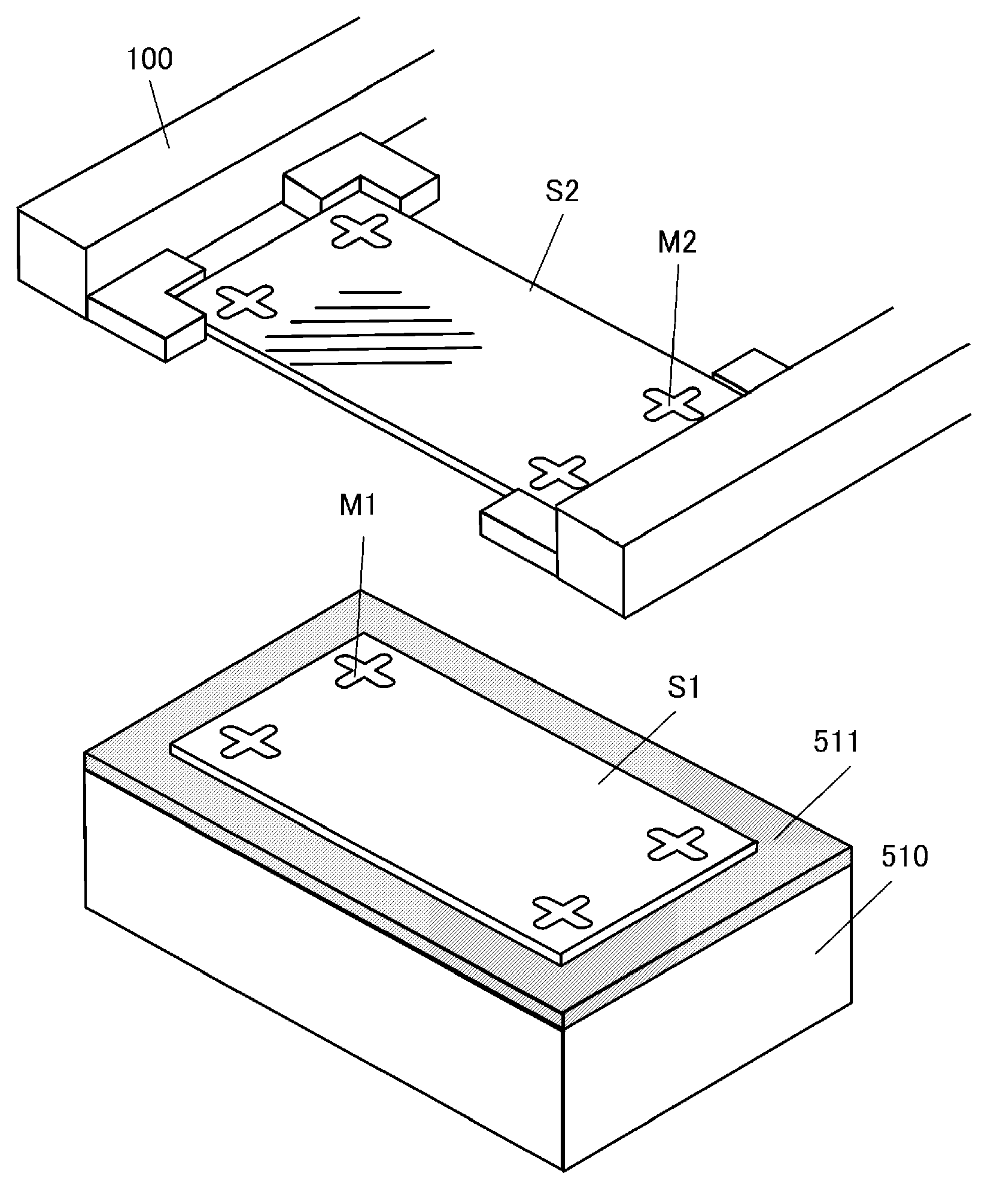

[0090] Such as figure 2 as well as image 3 As shown, the holding device 2 is a device for holding the workpiece S1 and the workpiece S2 facing up and down. In this embodiment, rectangular-shaped board|substrates, such as a liquid crystal module and a cover panel, are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com