Tundish with molten steel sampling connector

A technology of tundish and sampling port, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems that molten steel is easily mixed into slag layer substances, and sampling is inconvenient, so as to achieve convenient operation and accurate detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

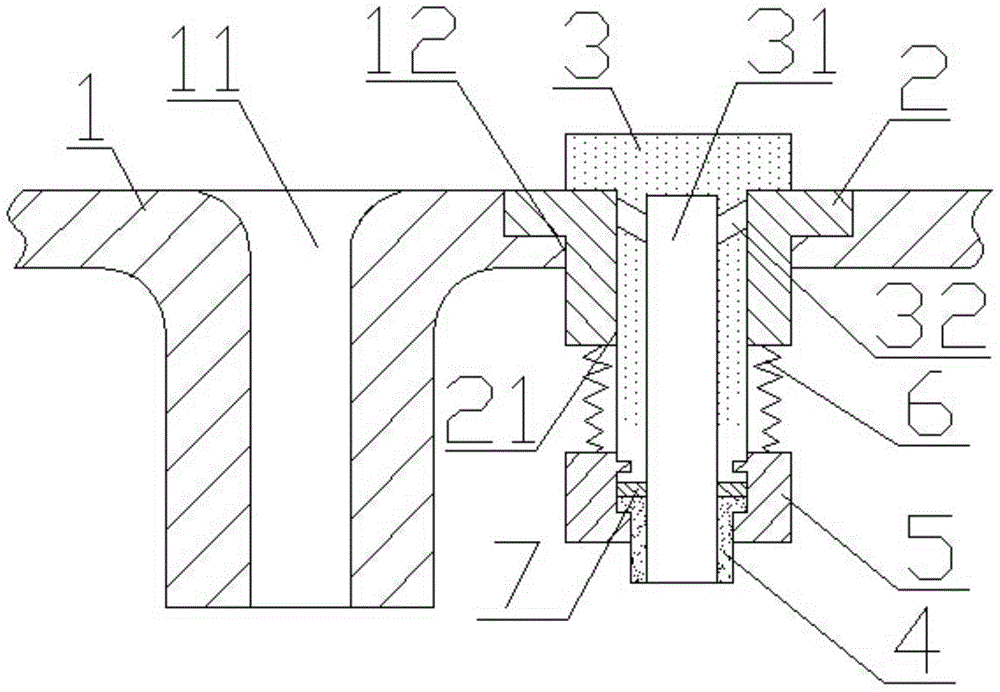

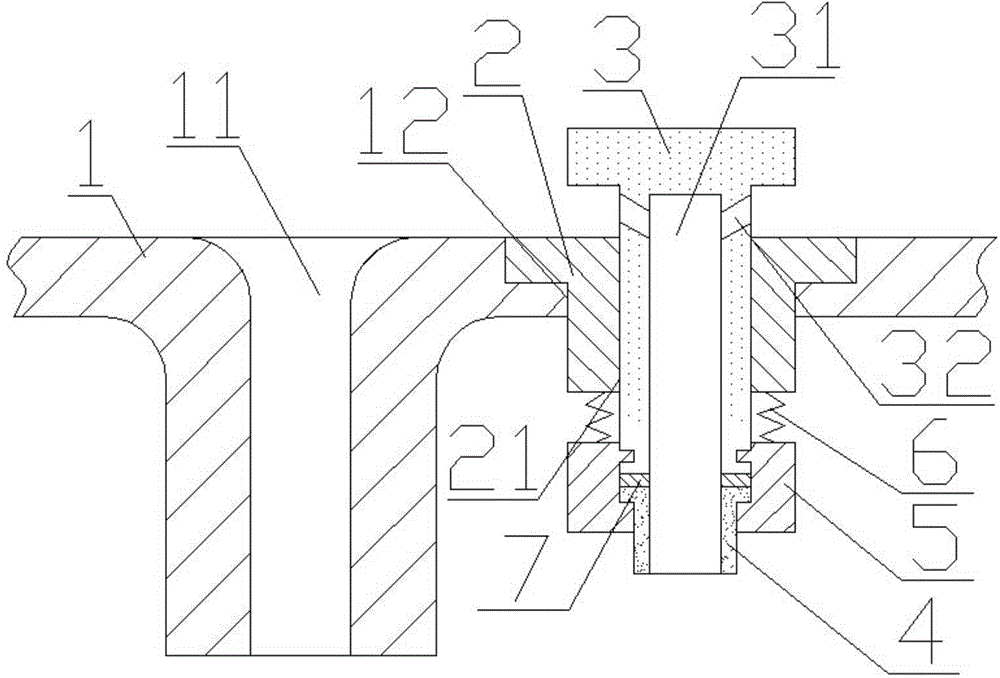

[0015] Such as figure 1 As shown, a tundish with a liquid steel sampling interface includes a nozzle 11 arranged on the bottom wall 1 of the tundish, and a mounting hole 12 with steps is also provided on the bottom wall 1, and the mounting hole 12 is arranged near the nozzle 11. The installation hole 12 is arranged near the nozzle 11, so that the molten steel sample obtained is the same as the composition of the molten steel at the outlet 11. The installation hole 12 is provided with a sampling port block 2 whose longitudinal section is a "T" shape. 2 There is a through hole 21 in the middle, and the through hole 21 is provided with a diversion plug 3 that can slide up and down along the through hole 21. The longitudinal section of the diversion plug 3 is "T" shape, and the diversion plug 3 is provided with a diversion Channel 31, diversion ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com