A clamping method for transformer iron core iron yoke

A clamping method and transformer technology, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor magnetic cores, electrical components, etc., can solve problems such as excessive noise, fastening of bolts in place, and chip shifting, etc., to reduce noise and Loss, increased clamping force, and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

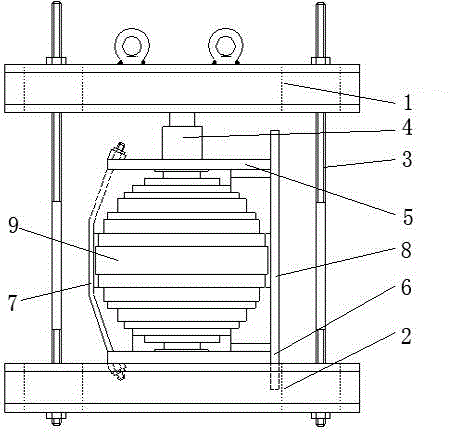

[0011] A special tooling for clamping iron core yokes of transformers, including an upper clamping beam 1, a lower clamping beam 2, and a clamping screw 3, and the four corners of the upper clamping beam and the lower clamping beam are set to match each other. The four clamping screws respectively penetrate into the holes at the four corners, and are fastened by bolts to form a frame structure. The holes of the upper clamping beam and the lower clamping beam are oblong holes, which are used to adjust the gap between the clamping screws. The distance between the clamping screw and the end thread of the clamping screw is used to adjust the distance between the upper clamping beam and the lower clamping beam, which is suitable for iron cores of different diameters.

[0012] A method for clamping the iron core yoke of a transformer. The above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com