Tension leg platform with improved hydrodynamic performance

A tension leg platform, horizontal technology, applied in the direction of fluid dynamics/hydrostatics characteristics, motor vehicles, floating buildings, etc., can solve high-risk, expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] US Patent No. 7,140,317, issued November 28, 2006 to Wybro et al., entitled "Central Pontoon Semisubmersible Floating Platform," is incorporated herein by reference in its entirety.

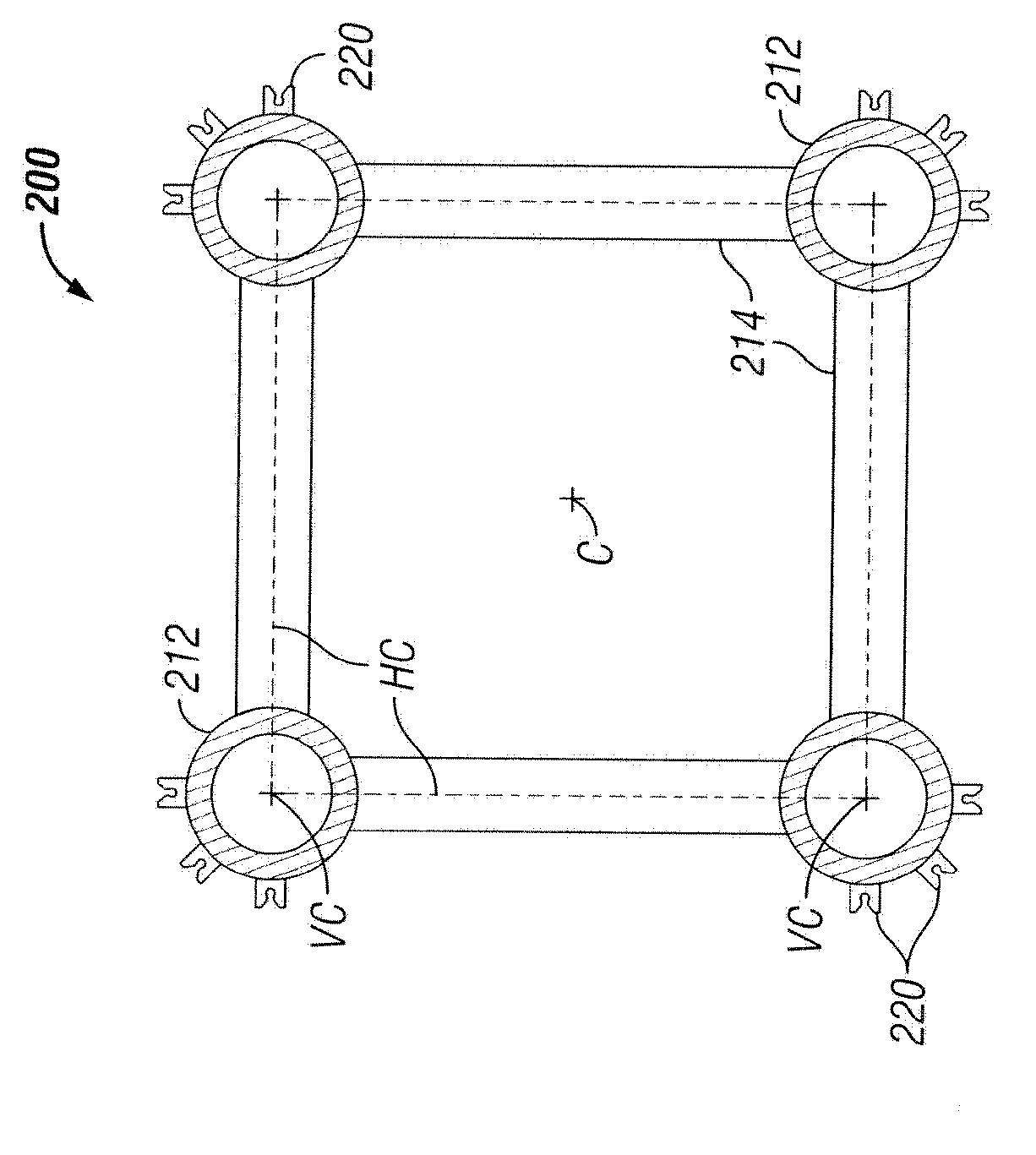

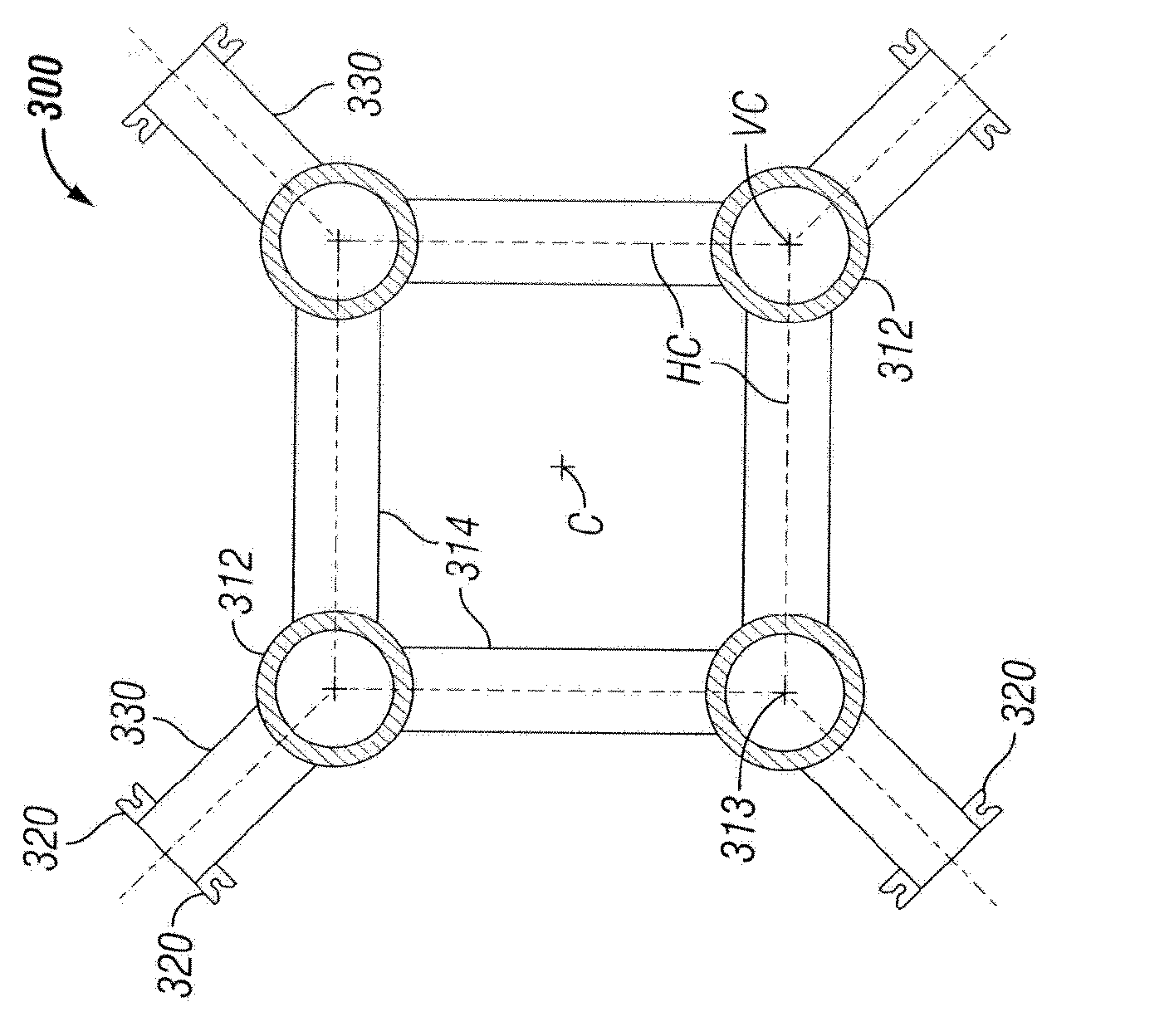

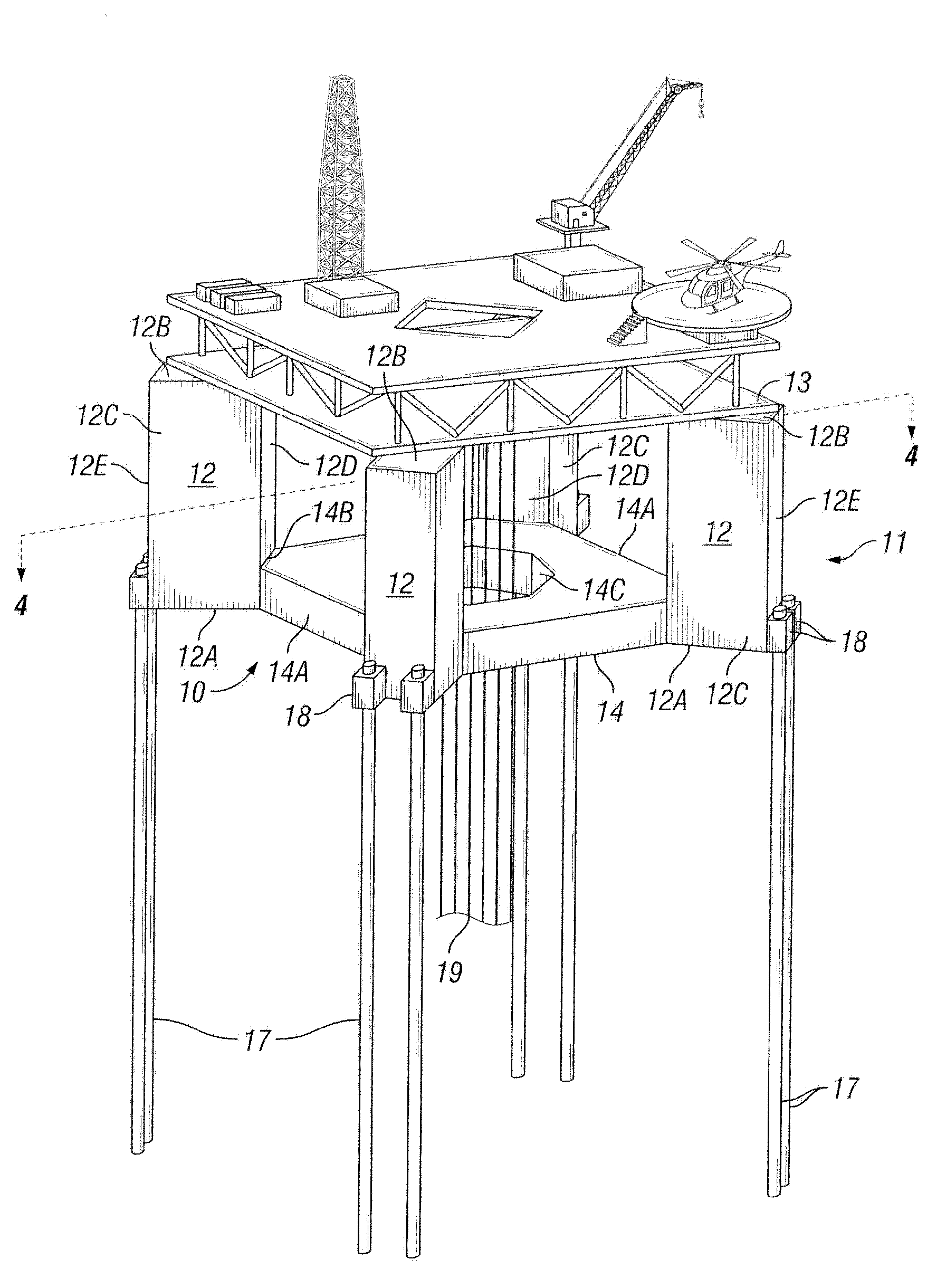

[0033] image 3 and Figure 4 A tension leg platform 10 for offshore applications such as offshore oil and gas drilling and production is shown according to a preferred embodiment of the present invention. The platform 10 has a hull 11 comprising a vertical support column 12 and a central pontoon structure 14 arranged inside the column at its lower end. The TLP 10 includes a deck structure 13 supported by the upper ends of columns 12 .

[0034] The interior of both the column 12 and the buoy structure 14 are preferably separated by a structural bulkhead (not shown) to strengthen the structure to provide an enclosed space for locating and storing various equipment (e.g., anchors, chains, propulsion mechanisms, etc.) , and in order to provide a plurality of individual tanks for ballasting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com