Molybdenum-wire three-guide-wheel tensioning system

A technology of tensioning system and guide wheel, which is applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems affecting the tension sensitivity of molybdenum wire, the trouble of winding wire, the rough processing of fast wire cutting, etc., and achieve the replacement of molybdenum Convenient silk, high processing quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

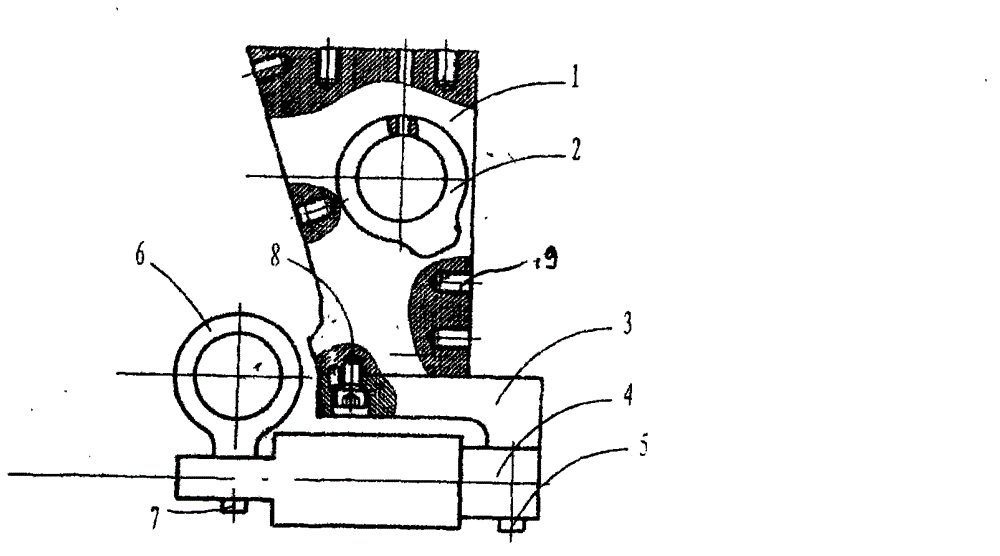

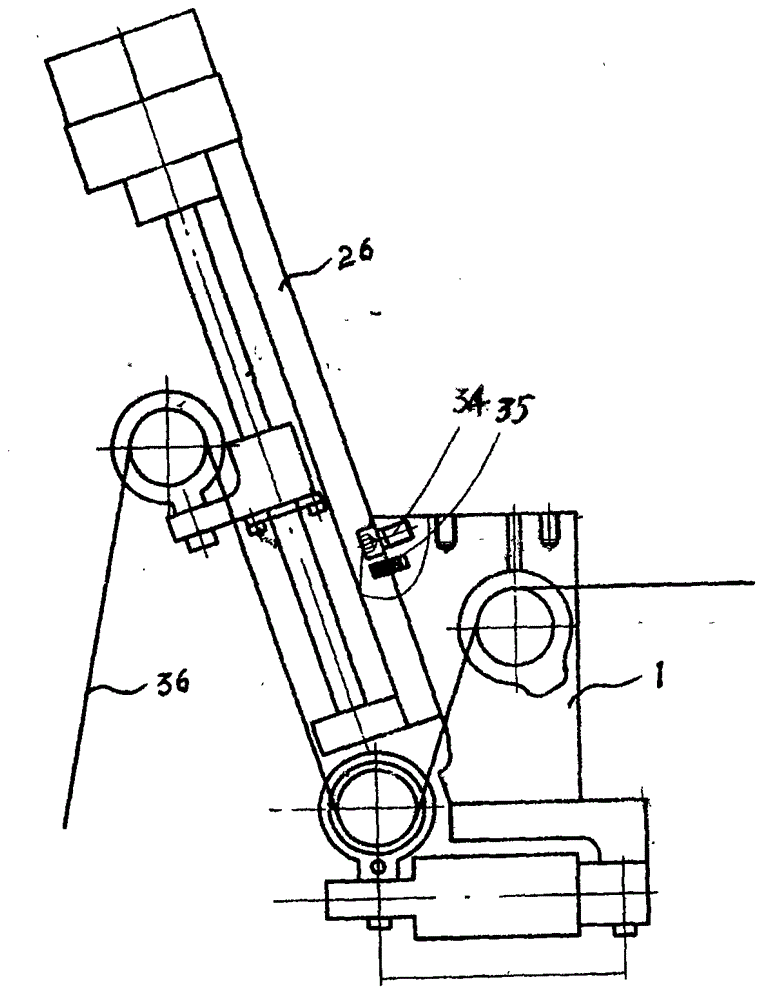

[0017] exist figure 1 Among them, the force measuring part is composed of base 1, guide wheel A 2, guide wheel B 6, transition plate 3, load cell 4, and screws 5, 7, 8, and the front side of the base 1 is set as an outwardly inclined The inclined plane, the base is fixed on the machine frame with screws through screw holes 9. Guide wheel armor 2 is fixed on one side of base by guide wheel seat. The transition plate 3 is made into a right angle, and is connected with the lower end of the base with a screw 8, and one end of the load cell 4 is fixed with the other right-angle side of the transition plate with a screw 5, and the other end of the load cell 4 is passed through a screw 7 Fix guide wheel B 6.

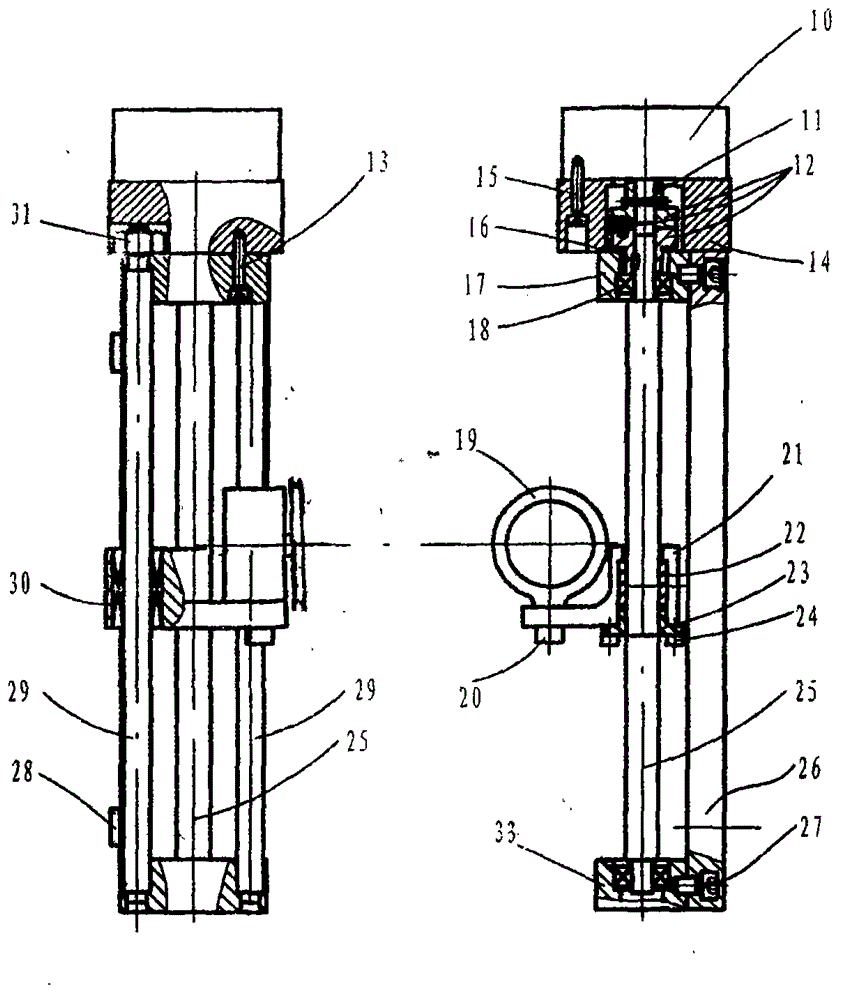

[0018] exist figure 2 Among them, the transmission part consists of base plate 26, stepping motor 10, coupling 12, coupling seat 14, guide post 29, screw rod 25, linear bearing 30, thread block 22, movable seat 21, guide wheel C 19, limit switch 28 , bearings 18, screws an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com