Buffer for storing energy and assisting power for electric automobile

A technology for electric vehicles and buffers, applied to vehicle components, auxiliary drive devices, control devices, etc., can solve problems such as damage to electrical components, and achieve the effects of increasing mileage, increasing output power, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

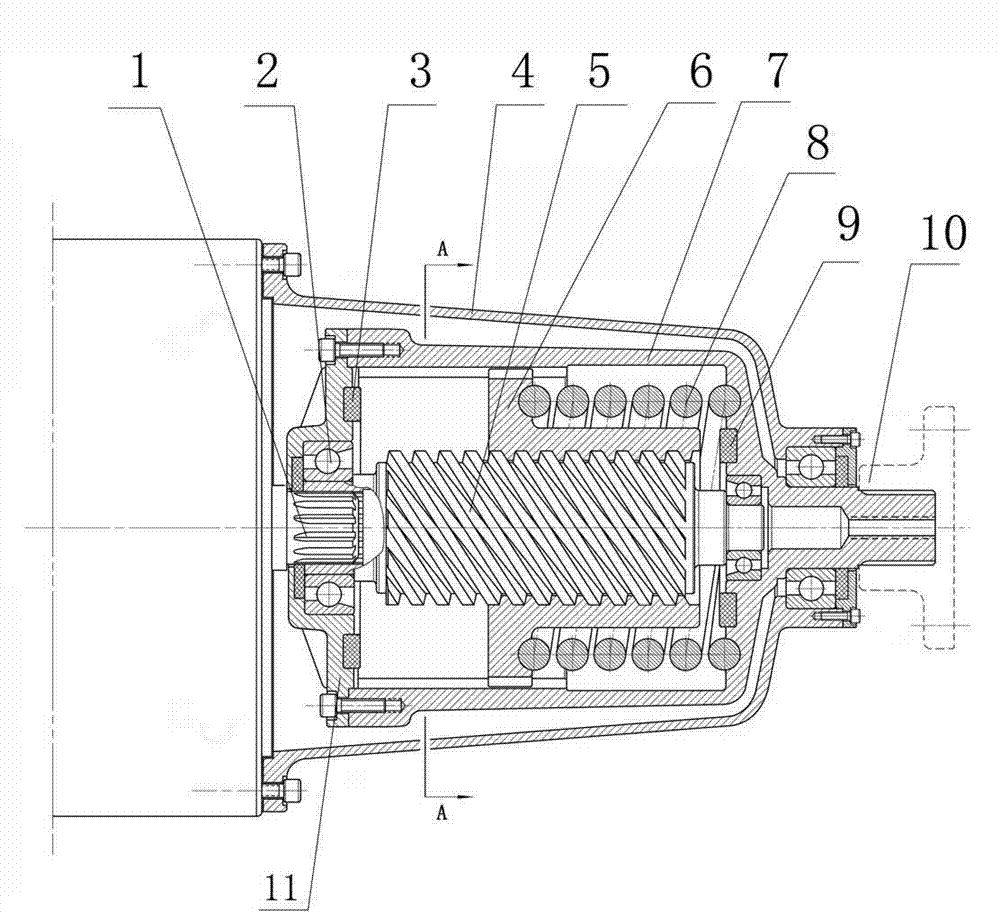

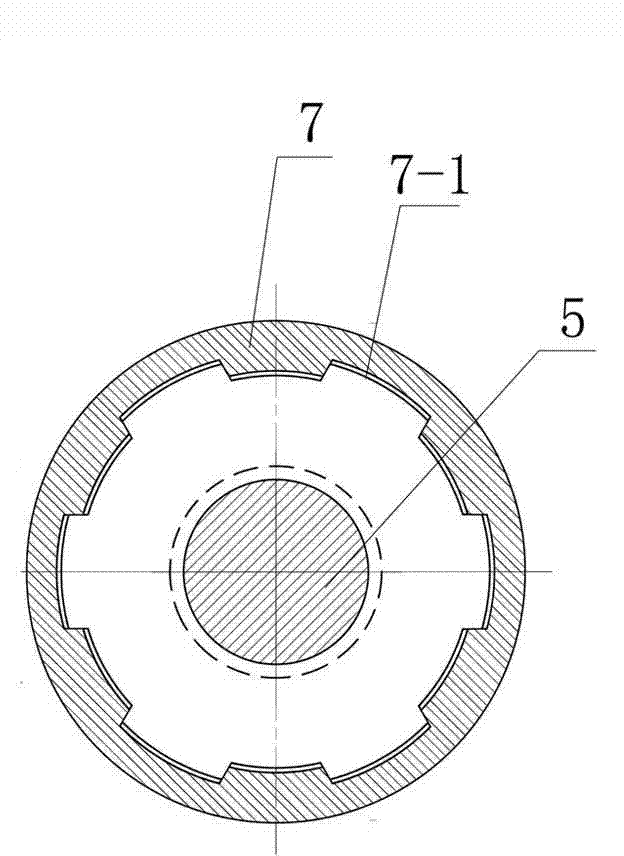

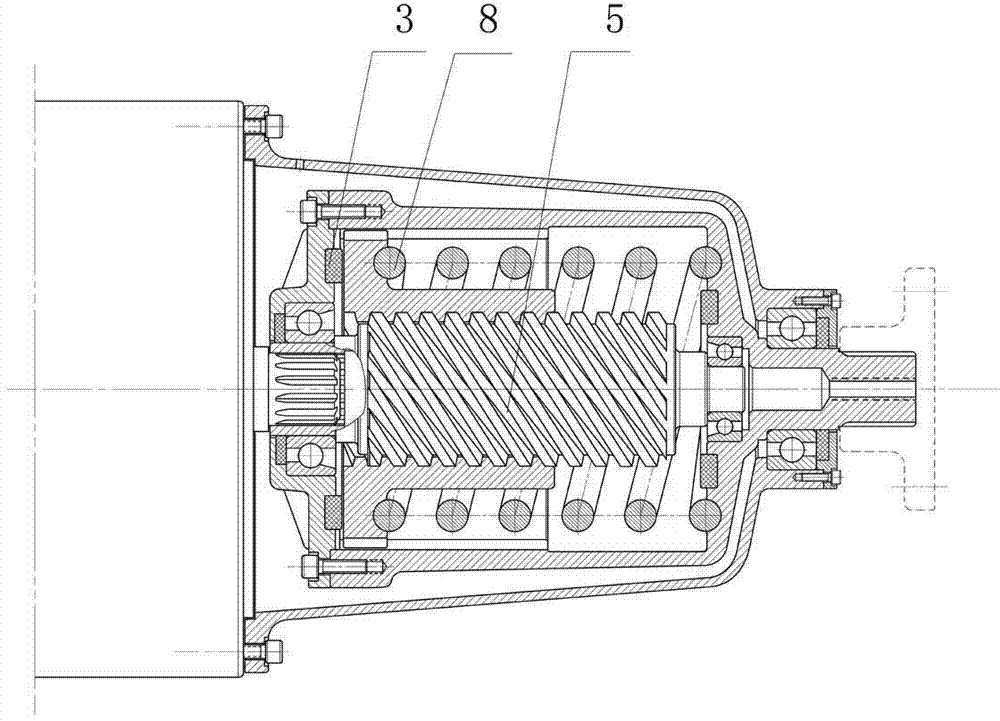

[0025] Such as figure 1 As shown, the energy accumulator described in this embodiment is mainly composed of a screw spindle 5 , a spline nut 6 , an energy storage spring 8 , an inner spline output bushing 7 , a casing 4 and an end cover 11 . The central inner hole of the spline nut 6 is connected with the outer helix of the screw main shaft 5, one end of the energy storage spring 8 is connected with the spline nut 6, and the other end is connected with the inner spline output sleeve 7, and the inner spline output shaft One end of the sleeve 7 is connected to the end cover 11, and the other end is connected to the terminal output shaft 10. The middle part of the inner spline output shaft sleeve 7 has a hollow cavity structure. In the hollow cavity of the output shaft sleeve. A single row centripetal thrust ball bearing 2 is arranged in the middle of the end cover 11, and an overload buffer rubber ring 9 is arranged on the inner end surface of the inner spline output shaft slee...

Embodiment 2

[0038] like Figure 4 As shown, the accumulator includes an overrunning clutch 12, a coil spring 13, a coil spring output sleeve 14 and a terminal output shaft 10, the coil spring 13 is wound on the coil spring output sleeve 14, and one end of the coil spring 13 is connected to the overrunning clutch active part 12-1 is connected, and the other end is connected with the coil spring output shaft sleeve 14; one end of the coil spring output shaft sleeve 14 is connected with the overrunning clutch follower 12-2, and the other end is connected with the terminal output shaft 10 through a spline.

[0039] The working principle and working process of the present embodiment are set forth below:

[0040] The overrunning clutch 12 is connected with the drive motor main shaft 1 . When the vehicle starts, because the starting resistance is very large and cannot be started synchronously at once, the sudden fast rotation of the drive motor main shaft 1 can only make the first rotation with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap