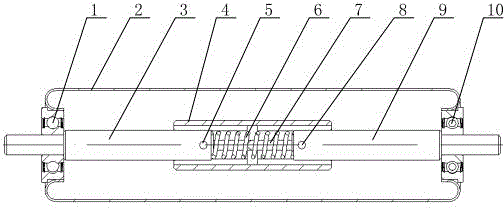

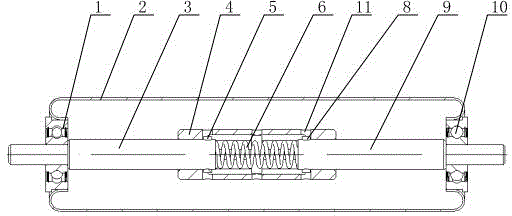

Installation structure of spring press-in type roller

An installation structure and press-in technology, which is applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of easy falling and installation difficulties, so as to improve installation efficiency, facilitate installation and disassembly, and avoid difficult The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 and figure 2 As shown, the installation structure of the spring-loaded roller in this embodiment includes a roller body 2, a roller shaft and bearings, the roller shaft runs through the center of the roller, and the roller shaft includes a first roller shaft 3 and a second roller shaft 9, The ends of the first drum shaft 3 and the second drum shaft 9 are supported and installed on the drum shell 2 through the first bearing 1 and the second bearing 10 respectively; a spring 6 is installed between the first drum shaft 3 and the second drum shaft 9 , The outer peripheral surface of the spring 6 is covered with a sleeve 4, and the two ends of the sleeve 4 are fastened to the first roller shaft 3 and the second roller shaft 9 through fasteners respectively.

[0020] The length of the sleeve 4 is greater than that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com