Method for judging reduction leaching degree of concentrate containing trivalent cobalt in production site

A technology of trivalent cobalt and concentrate, which is applied to the improvement of process efficiency, chemical analysis by micro-analysis, electrochemical variables of materials, etc., which can solve the waste of reducing agent, increase the difficulty and cost of subsequent purification process, and cost loss Advanced problems, to achieve the effect of reducing content, reducing processing difficulty and cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

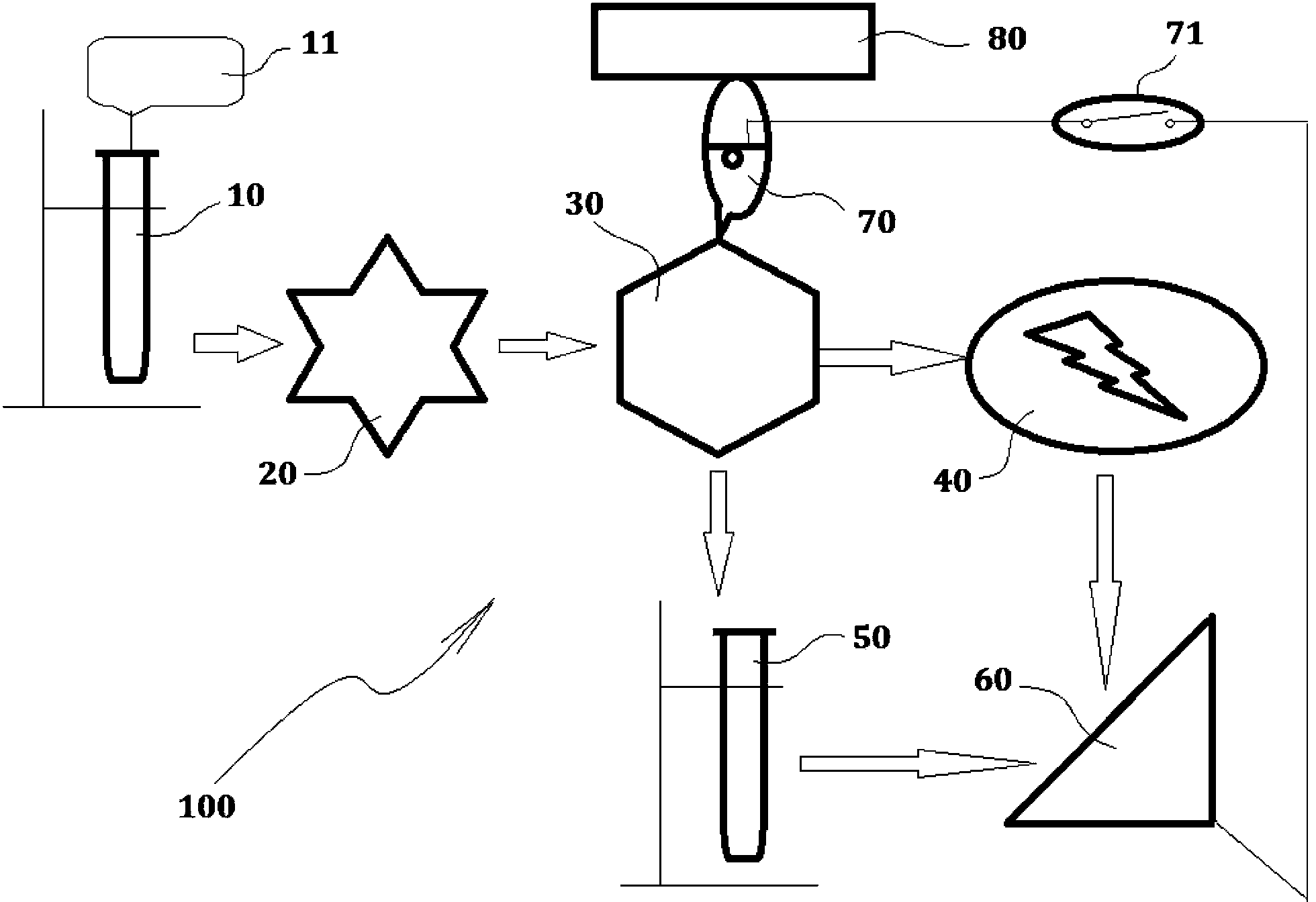

Method used

Image

Examples

Embodiment 1

[0043] 1) On-site detection of Fe in slurry containing trivalent cobalt concentrate 2+ The value is 0.36g / L;

[0044] 2) add acid to carry out acid-dissolving reaction, and add reducing agent sulfur dioxide, the detection potential of field potentiometer is 503mV, potassium dichromate titration titration Fe 2+ It is 0.91g / L; continue to add sulfur dioxide to react, the detection potential of field potentiometer is 375mV, potassium dichromate titration titration Fe 2+ It was 2.73g / L; continue to add sulfur dioxide to react, the on-site detection potential is 265mV, potassium dichromate titration titration Fe 2+ 8.50g / L;

[0045] 3) stop adding reducing agent;

[0046] 4) Continue to react for 0.5 hour, and the reaction ends. The iron content of the solution obtained from the reaction is 10.8g / L, and the leaching slag contains 0.10% of insoluble cobalt, reaching the discharge standard.

Embodiment 2

[0048] 1) On-site detection of Fe in slurry containing trivalent cobalt concentrate 2+ The value is 0.54g / L;

[0049] 2) Add acid to carry out acid-dissolving reaction, and add reducing agent sulfur dioxide, the on-site detection potential is 120mV, titrate Fe 2+ 6.1g / L;

[0050] 3) stop adding reducing agent;

[0051]4) Continue to react for 1 hour, and the reaction ends. The iron content of the solution obtained from the reaction is 9.17g / L, and the insoluble cobalt contained in the leaching residue is 0.07%, reaching the discharge standard.

Embodiment 3

[0053] 1) On-site detection of Fe in slurry containing trivalent cobalt concentrate 2+ The value is 0.17g / L;

[0054] 2) Add acid for acid dissolution reaction, and add reducing agent sodium metabisulfite, the on-site detection potential is 455mV, titrate Fe 2+ It is 3.5g / L; Continue to add sodium metabisulfite, the on-site detection potential is 345mV, potassium dichromate titration titration Fe 2+ 3.70g / L;

[0055] 3) stop adding reducing agent;

[0056] 4) Continue to react for 1.5 hours, and the reaction ends. The iron content of the solution obtained from the reaction is 5.10g / L, and the leaching residue contains 0.14% of insoluble cobalt, reaching the discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com