Preparation process of fluoroethylene carbonate

A technology of fluoroethylene carbonate and chloroethylene carbonate, which is applied in the field of preparation technology of fluoroethylene carbonate, can solve problems such as difficult refining and removal, increased equipment investment, troublesome production control, etc., and achieves reduction of by-product generation, Reduction of reaction time and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

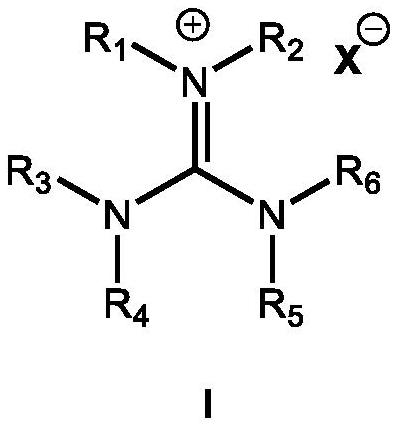

Method used

Image

Examples

Embodiment 1

[0043] S1: Pretreatment: Distillation pretreatment of 80% grade of chlorinated vinyl carbonate (81.2%) of commercially available raw materials, after removing low boiling, collect fractions at 200-300Pa and temperature 80-90 °C, and the purity of chlorinated vinyl carbonate reaches 94.7%;

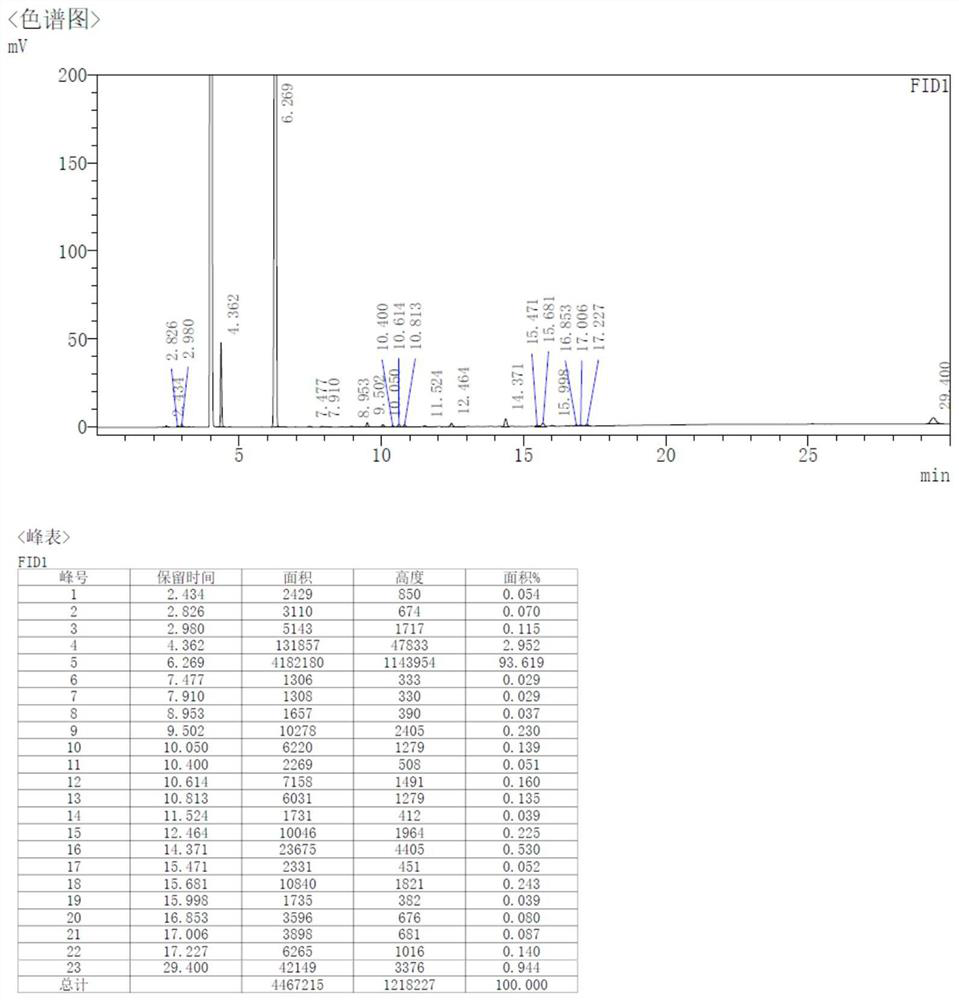

[0044] S2: Fluoridation: 500g of diethyl carbonate, 170g of potassium fluoride, 0.6g of hexamethyl fluoride into the reactor, dehydrated at atmospheric pressure at 120-130 °C to ≤ 0.1% of the distilled water, cooled to 70-80 °C to start adding 300g of chlorinated vinyl carbonate (according to the purity of chlorinated vinyl carbonate, the same below), about 2 hours of dropwise addition, insulation reaction for 3 hours, filtration, dissolution to obtain fluorovinyl carbonate; from Figure 1 The results of the reaction solution analysis can be seen that the purity of fluorovinyl carbonate is 93.6% (6.3min), the content of chlorinated vinyl carbonate is < 0.5% (9.5min), and the basic unparalleled f...

Embodiment 2

[0050] S1: pretreatment: 80% of the raw material grade of chlorovinyl carbonate (same as Example 1) distillation pretreatment, after removing low boiling, collect 200-300Pa, temperature 80-90 °C distillate, chlorovinyl carbonate purity of 94.6%;

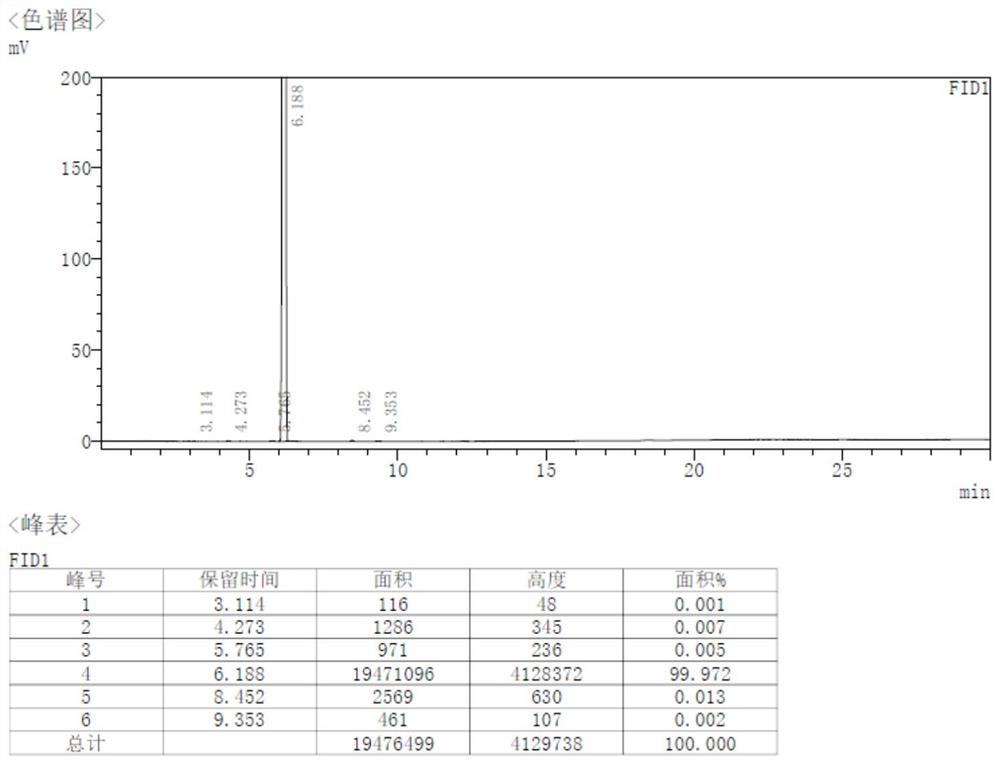

[0051] S2: Fluorination: 500g diethyl carbonate, 170g potassium fluoride, 0.75g hexamethyl fluoride into the reactor, dehydrated at atmospheric pressure at 120-130 °C to ≤ 0.1% of the distilled water, cooled to 70-80 °C to start the titration treatment of 300g of chlorovinyl carbonate, about 2 hours of drop-added end, insulation reaction for 3 hours, filtration, dissolution to obtain a purity of 94.4% of fluorinated carbonate, chlorinated vinyl carbonate content of <0.5%;

[0052] S3: Refining:

[0053] S3-1 put the concentrate into the treatment kettle, cool down to -10 °C at a speed of 5 °C / hour, stop cooling, open the bottom valve of the kettle, flow out of the non-condensate, the kettle gradually heats up to 15 °C, about 2 hours la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com