A gangue bag filling method for wide roadway excavation in thin coal seam under hard roof

A technology with a hard roof and a thin coal seam, which is applied in the field of gangue bag filling, can solve problems such as environmental pollution in mining areas, and achieve the effects of simple process, reduced deformation, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

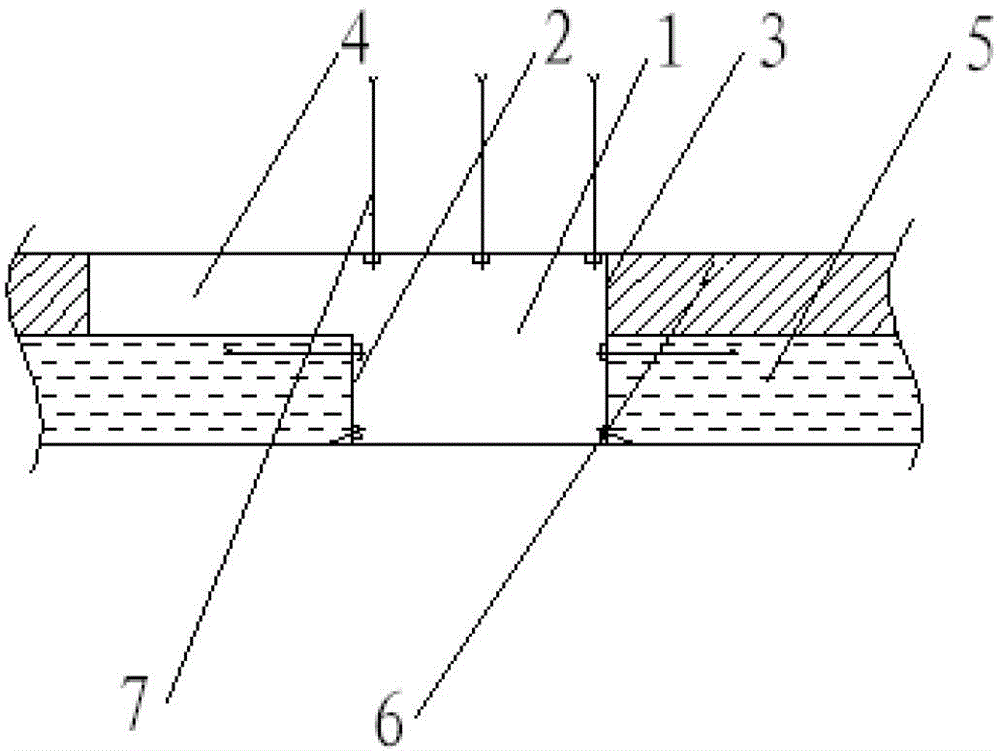

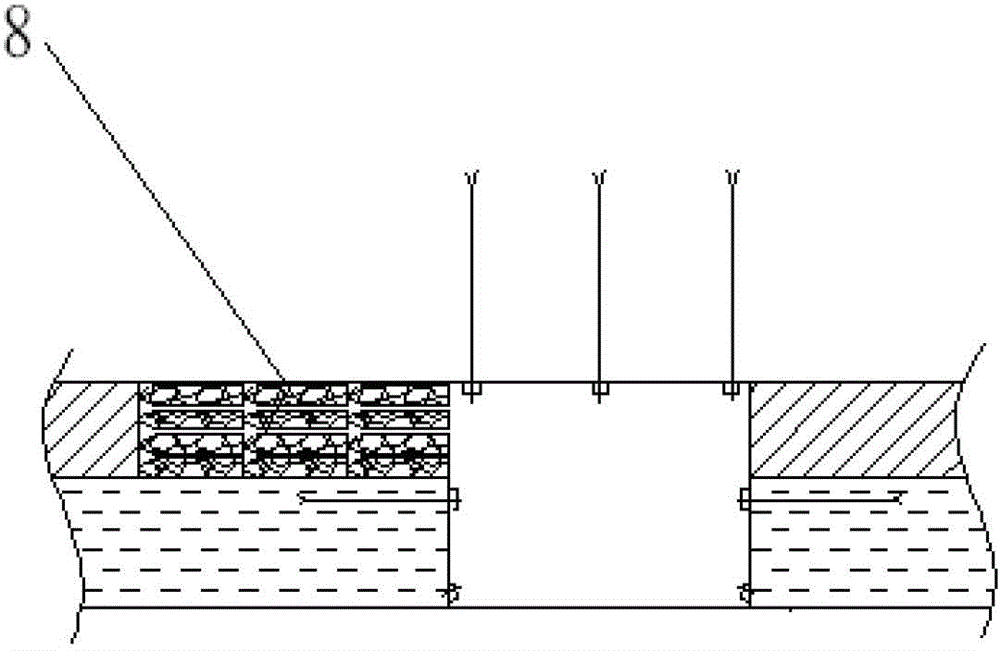

[0013] The preferred embodiment of the gangue bag filling method for thin coal seam wide roadway tunneling under a hard roof according to the present invention will be described in detail below with reference to the accompanying drawings.

[0014] In the process of underground thin coal seam, the roadway is excavated along the coal seam when the roadway is excavated. The original section size of the roadway is 3.4m wide and 2.5m high. Anchor rods are installed on the roadway roof, floor, inner and outer sides, and diamond-shaped metal mesh is hung on the end of the anchor rod to strengthen the support effect when necessary.

[0015] When the roadway is excavated to a length of 6m according to the original cross-section size, the filling roadway will be formed along the coal seam expansion on the outer side of the roadway. After starting to excavate and fill the roadway, the roadway and the filling roadway are excavated alternately, and the cycle is advanced, that is, the roadw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com