Intercooler device for diesel engine

A technology for diesel engines and coolers, which is applied in the direction of machines/engines, mechanical equipment, combustion engines, etc. It can solve the problems of large number of parts, large occupied volume, and non-compactness, etc., and achieves less installation and positioning links, reasonable occupied space, and easy processing The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

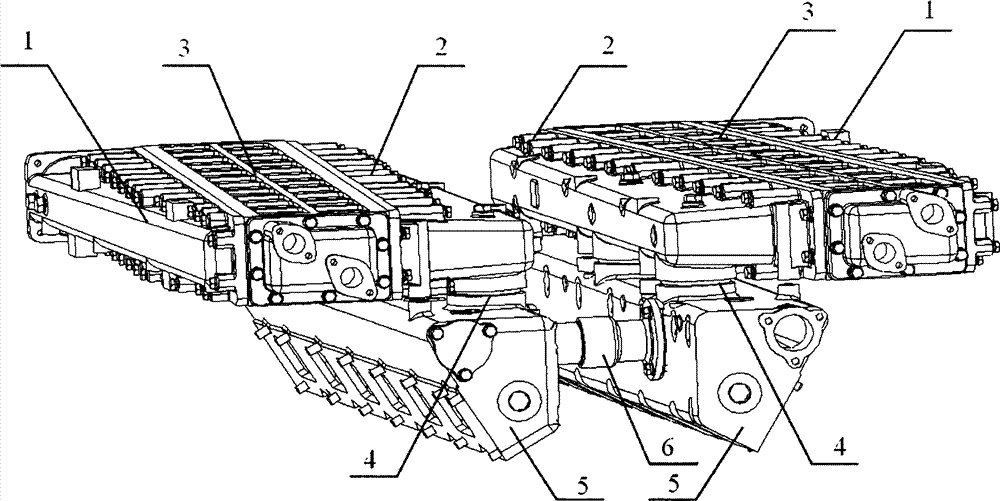

[0012] The intercooler is placed on the top of the diesel engine, which makes the space occupied by the intercooler more reasonable and realizes the function of the intercooler. The pipeline between the intercooler and the intake pipe is more concise, reducing the volume of diesel engine parts and making it more compact There are few links in the installation and positioning of the cooler, and the overall disassembly and assembly are easy.

[0013] For a V-type engine, its cylinders are divided into two rows. In order to use the space more effectively and further realize the compactness of the engine, the technical solution of the intercooler is: a diesel engine intercooler device, including an intake cover 1 and an air outlet cover. 2. The intercooler core 3, the intake pipe 4, and the air intake pipe 5 are characterized in that: the air intake cover 1, the air outlet cover 2, the intercooler core 3, and the intake pipe 4 are located in the intake pipe 5 upper part: intake ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com