Verticality symmetry inspection tool of differential shell

A verticality and symmetry technology, which is applied in the field of verticality symmetry inspection tools for differential housings, can solve the problems of complex detection process, low detection accuracy, and high detection cost, and achieve simple detection process, high detection accuracy and high detection cost. low cost effect

Inactive Publication Date: 2013-02-27

SHENYANG HONGDA INFORMATION TECH

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the vertical symmetry inspection tool of the automobile differential case generally adopts three-coordinate equipment, which has high inspection cost. Since the X-axis, Y-axis and Z-axis are required for joint inspection, the inspection process is complicated and the inspection cycle is long. The accuracy is low, and at the same time, it is necessary to go to a specific testing location, which cannot realize on-site testing and is inconvenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The detailed structure of the present invention is illustrated in conjunction with examples.

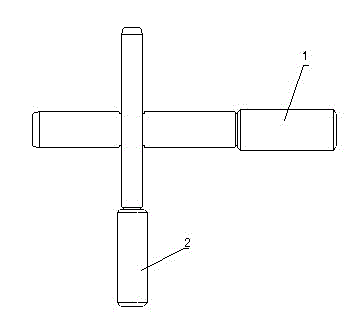

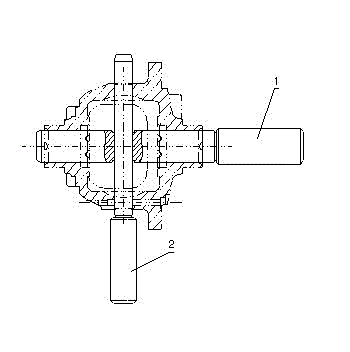

[0010] Such as figure 1 and 2 As shown, it includes a mandrel 1 and a positioning mandrel 2, wherein the center of the positioning mandrel 2 is provided with a positioning hole, and the mandrel 1 is inserted into the positioning hole and connected with the positioning mandrel 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A verticality symmetry inspection tool of a differential shell belongs to the technical field of automobile machining. The verticality symmetry inspection tool comprises a mandrel and a positioning mandrel, wherein the center of the positioning mandrel is provided with a positioning hole, and the mandrel is plugged into the positioning hole and connected with the positioning mandrel. Compared with the prior art, the verticality symmetry inspection tool has the beneficial effects that in-situ inspection can be realized, the inspection process is simple, the inspection precision is high, the inspection cost is low, and convenience in inspection is realized.

Description

technical field [0001] The invention belongs to the technical field of automobile processing, and in particular relates to a verticality symmetry inspection tool for a differential housing. Background technique [0002] At present, the vertical symmetry inspection tool of the automobile differential case generally adopts three-coordinate equipment, which has high inspection cost. Since the X-axis, Y-axis and Z-axis are required for joint inspection, the inspection process is complicated and the inspection cycle is long. The accuracy is low, and at the same time, it is necessary to go to a specific testing location, which cannot realize on-site testing and is inconvenient to use. Contents of the invention [0003] Aiming at the deficiencies in the prior art, the invention provides a verticality symmetry checker for a differential housing. [0004] The technical solution of the present invention is realized as follows: it includes a mandrel and a positioning mandrel, wherei...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B5/24G01B5/245

Inventor 李翠封仕燕

Owner SHENYANG HONGDA INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com