Melamine selective electrode and preparation method thereof

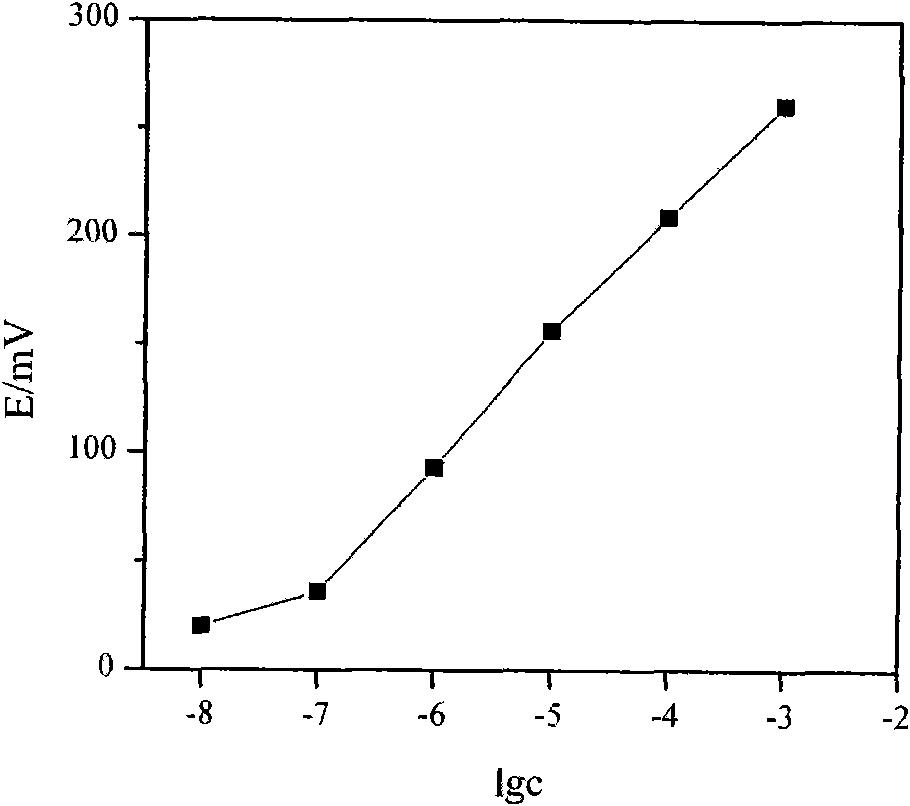

A melamine and selective technology, applied in the fields of chemical sensors and electro-analytical chemistry, can solve the problems of unsuitable on-site detection, expensive instruments, high analysis costs, etc., and achieve the effects of low analysis cost, fast detection speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

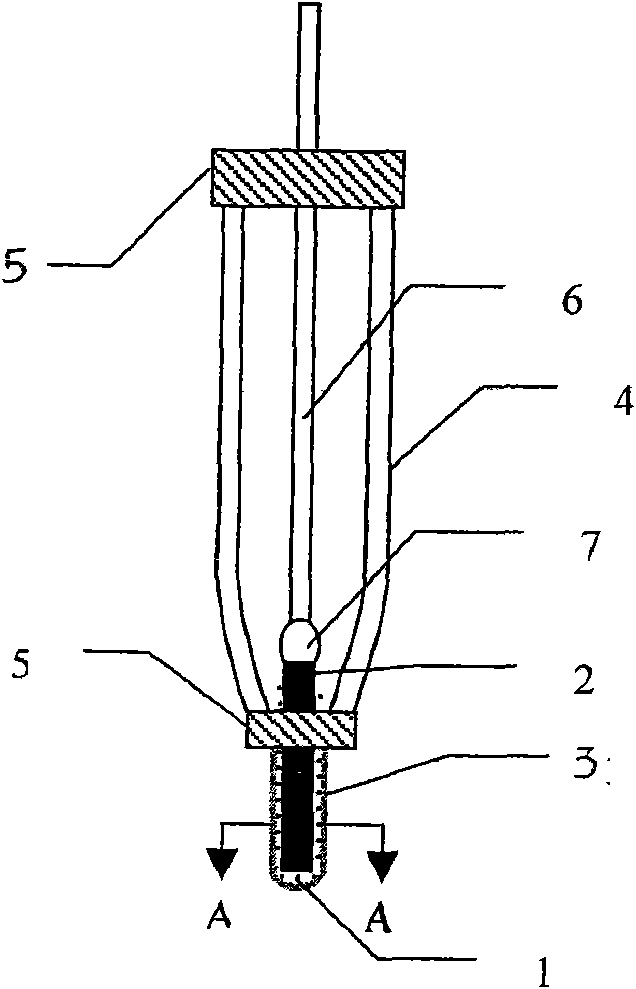

Method used

Image

Examples

Embodiment 1

[0034] The first step: the preparation of the dichloromethane solution of PMMA-PDMA containing electroactive substance, the steps are as follows:

[0035] ① Preparation of electroactive material:

[0036] Add 0.05g of melamine into 100mL of 0.01mol / L hydrochloric acid solution, after completely dissolving, mix with 10 -2 mol / L phosphotungstic acid solution 50mL mixed under stirring, let stand for 12h, filter, rinse the precipitate with deionized water 10 times, dry in a vacuum dryer for 12h, and then obtain the electroactive material;

[0037] ②Preparation of PMMA-PDMA dichloromethane solution:

[0038] Add 1 mL of methyl methacrylate (MMA) and 4 mL of dimethylaminoethyl methacrylate (DMA) into 5 mL of ethyl acetate, pass nitrogen gas for 10 min, add 3.4 mg of initiator azobisisobutyronitrile, stir and dissolve , continue stirring at 85°C for 16h, after the reaction is over, add the above product dropwise to 800mL distilled water, stir vigorously, dissolve the white precipit...

Embodiment 2

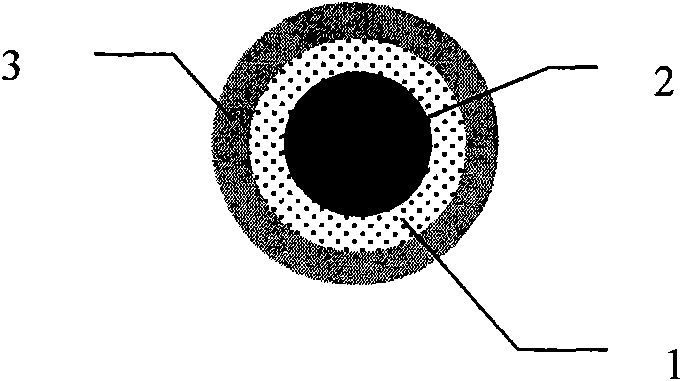

[0052] The base electrode (2) is an Au electrode;

[0053] Others are the same as embodiment 1, such as Figure 2-b .

Embodiment 3

[0055] Preparation of electroactive material: 0.1g melamine was added in 200mL of 0.05mol / L hydrochloric acid solution, mixed with 100mL 10 -2 The mol / L phosphotungstic acid solution was stirred and mixed, allowed to stand for 10 hours, filtered, the precipitate was rinsed with deionized water for 10 times, and dried in a vacuum dryer for 24 hours to obtain the electroactive material;

[0056] Others are the same as embodiment 1, such as Figure 2-c .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com