Heat exchanger thermal-cold circle fatigue experiment device

A technology of fatigue test and cold and heat cycle, applied in the direction of measuring device, machine/structural component test, instrument, etc., can solve energy waste, energy waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

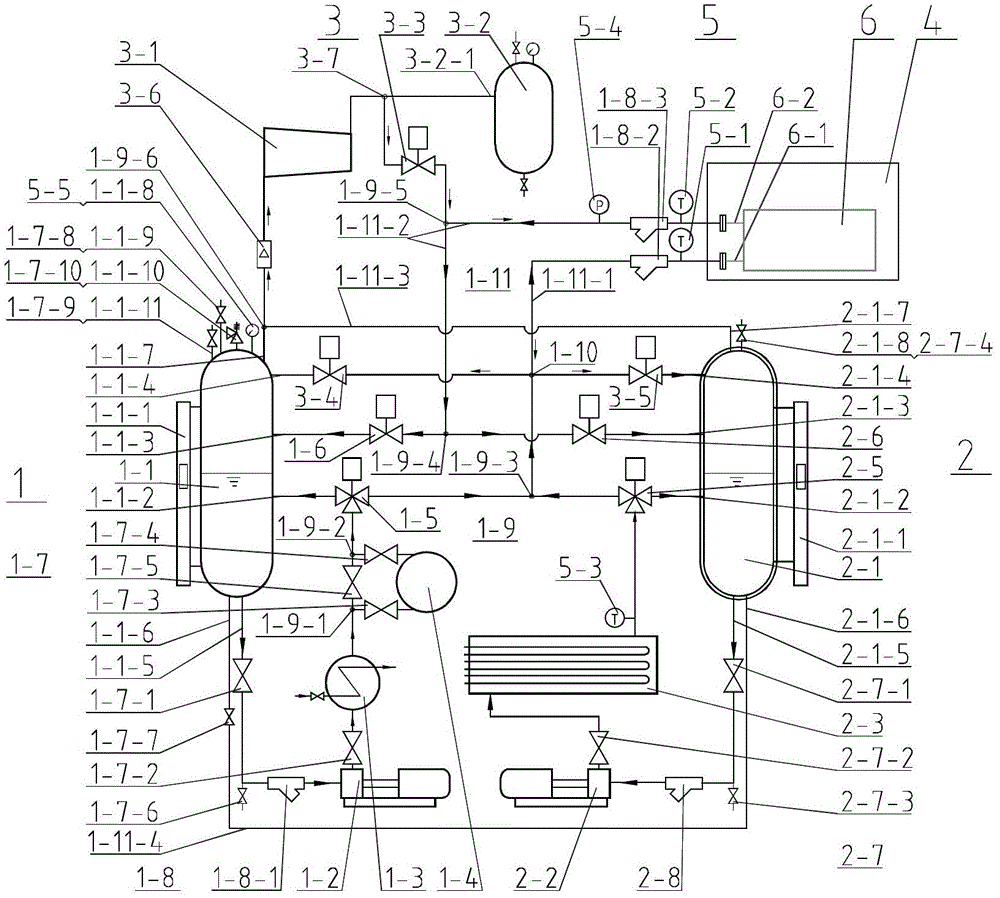

[0019] Examples see figure 1 ,

[0020] A heat exchanger cold and hot cycle fatigue test device, the cold and hot cycle fatigue test device includes a cold circuit 1, a hot circuit 2, a test piece cabinet 4, a control instrument group 5, and a test piece heat exchanger 6; the control instrument group 5 includes temperature sensor A5-1, temperature sensor B5-2, temperature sensor C5-3, pressure sensor 5-4 and pressure gauge 5-5; cold circuit 1 includes cold oil tank 1-1, cold oil pump 1-2, cooling Device 1-3, refrigerator 1-4, cold air three-way ball valve 1-5, cold air ball valve 1-6, cold valve group 1-7, cold filter group 1-8, cold three-way group 1-9, Four-way 1-10, connecting pipe group 1-11; cold valve group 1-7 includes valve A1-7-1, valve B1-7-2, valve C1-7-3, valve D1-7-4, valve E1 -7-5, valve F1-7-6, valve G1-7-7, valve H1-7-8, nitrogen supplement valve 1-7-9 and safety valve 1-7-10; cold filter group 1-8 Including filter A1-8-1, filter B1-8-2 and filter C1-8-3; co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com