Intelligent manufacturing equipment of knitted garments

An intelligent manufacturing and clothing technology, applied in the field of knitted garment manufacturing, can solve the problems of reducing the twisting speed, inability to fully utilize it, and affecting the manufacturing speed of knitted garments, etc., and achieve the goal of increasing the twisting speed, increasing the manufacturing speed, and reducing the twisting speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for manufacturing knitted garments, specifically as follows:

[0027] Step 1: Sampling the yarn raw materials to check whether the color fastness, moisture regain, linear density and uniformity of the yarn meet the standards;

[0028] Step 2: Wind the qualified yarn on the bobbin through the high-efficiency waxing integrated hank machine, and perform waxing treatment at the same time during the winding process, which can not only improve the manufacturing efficiency, but also the wound yarn Soft and smooth, smooth thread withdrawal during subsequent use;

[0029] Step 3: knitting the yarn into corresponding garment pieces by a knitting machine, and then stitching the garment pieces together to obtain a knitted garment;

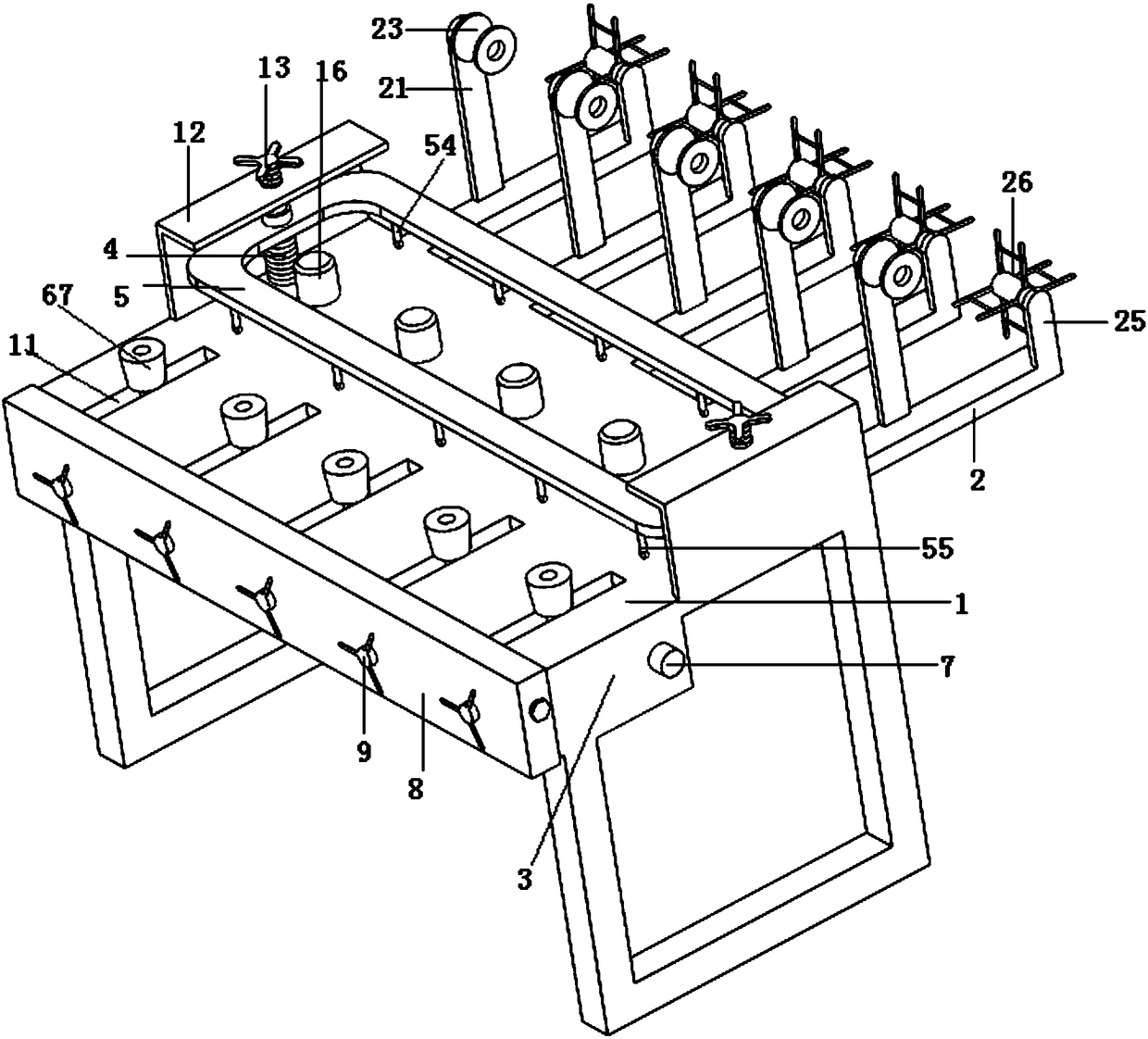

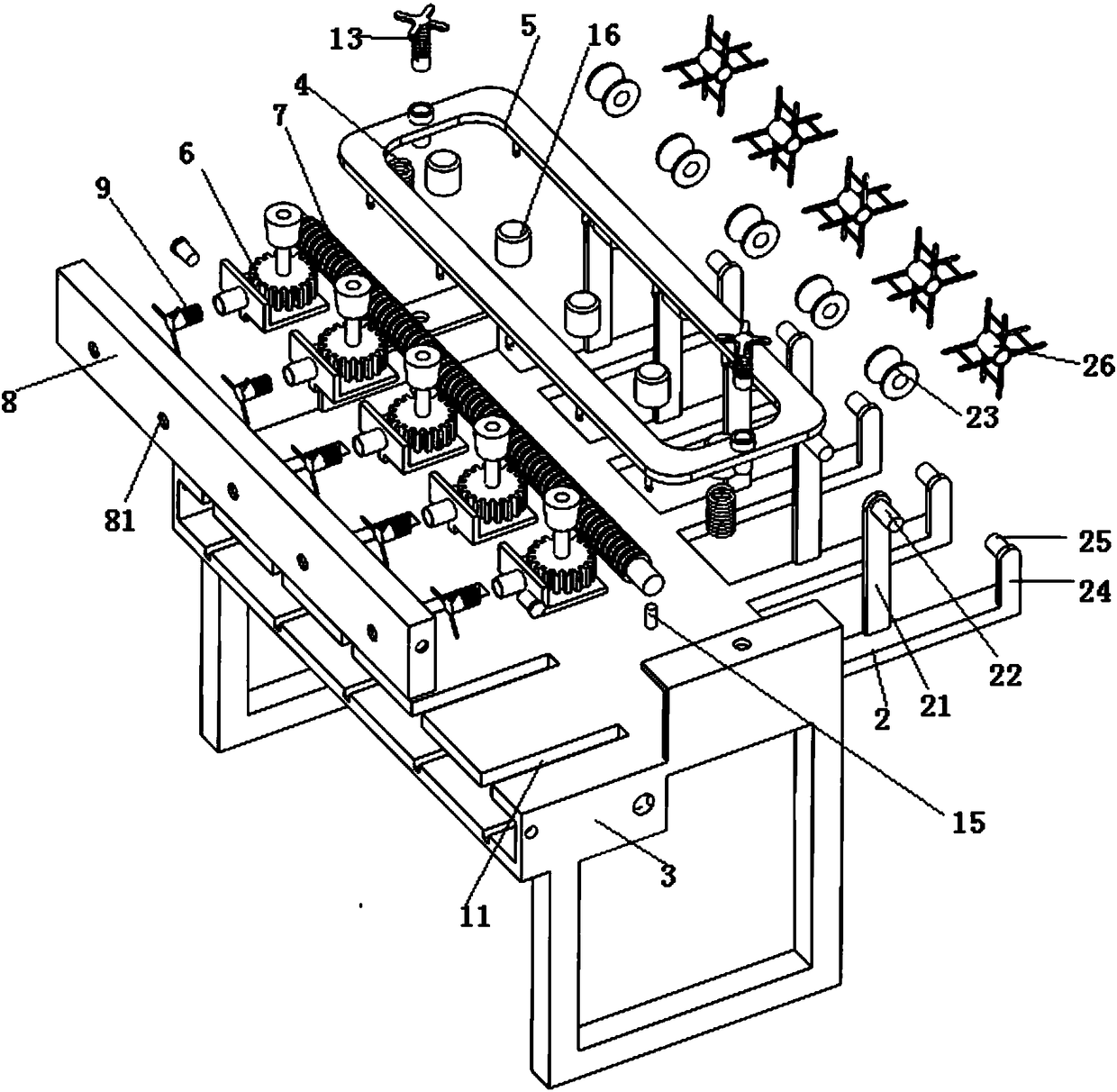

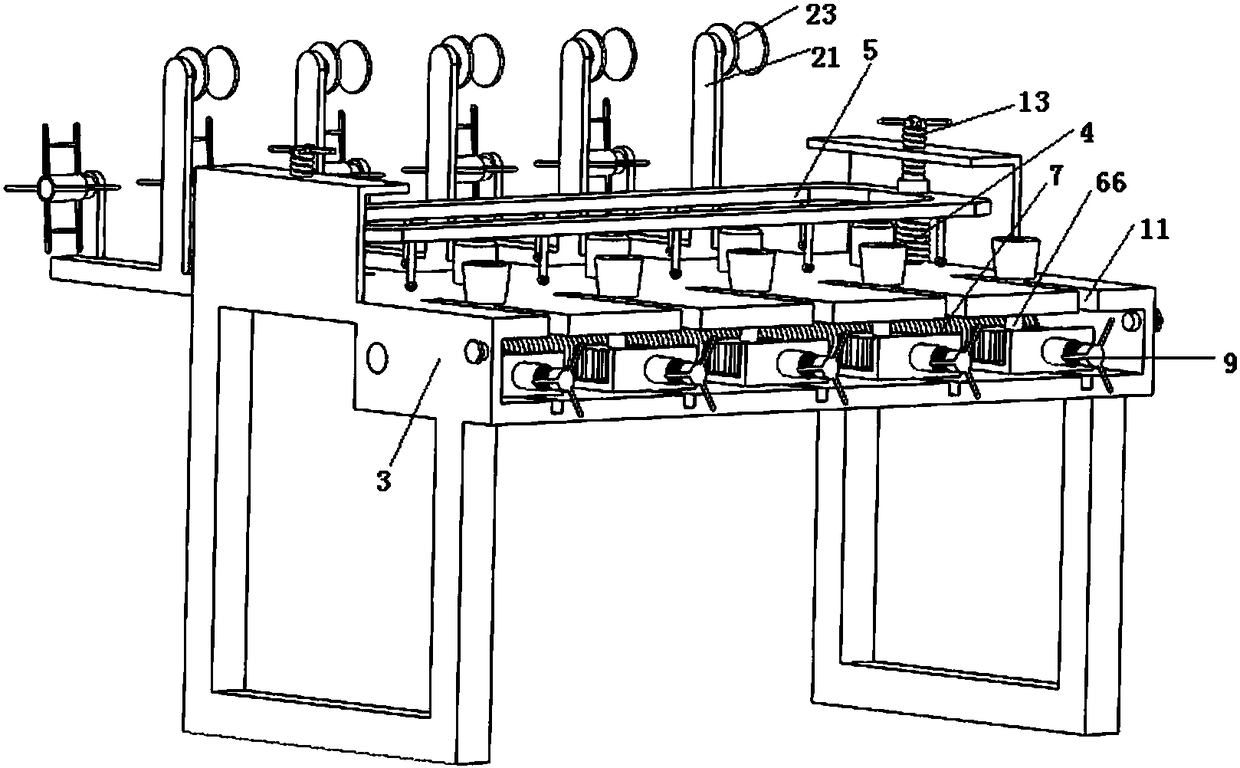

[0030] Wherein the high-efficiency waxing integrated hank machine includes a frame bearing plate 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the front side surface of the rack bearing plate 1 is integrally connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com