Combustion chamber constructions for opposed-piston engines

A technology of combustion chamber and internal combustion engine, which is applied in the field of combustion chamber and can solve the problems of reducing the speed of engine thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

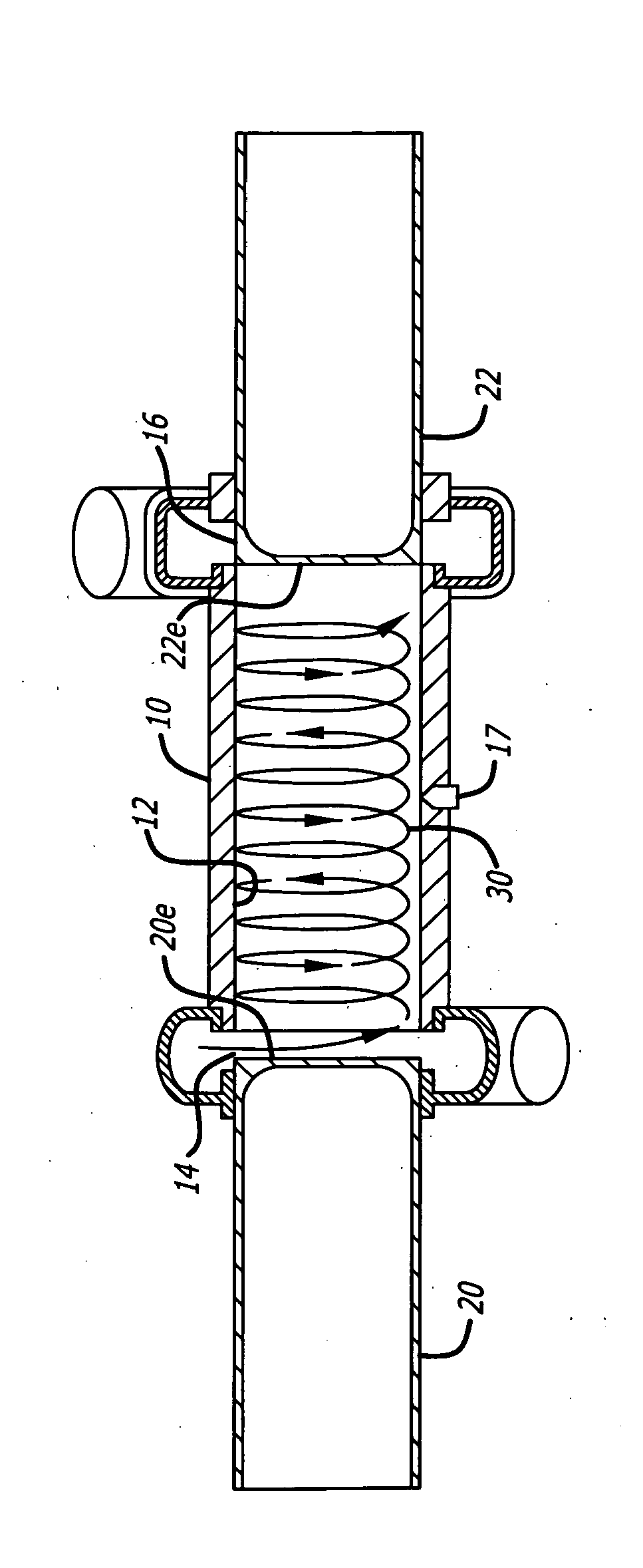

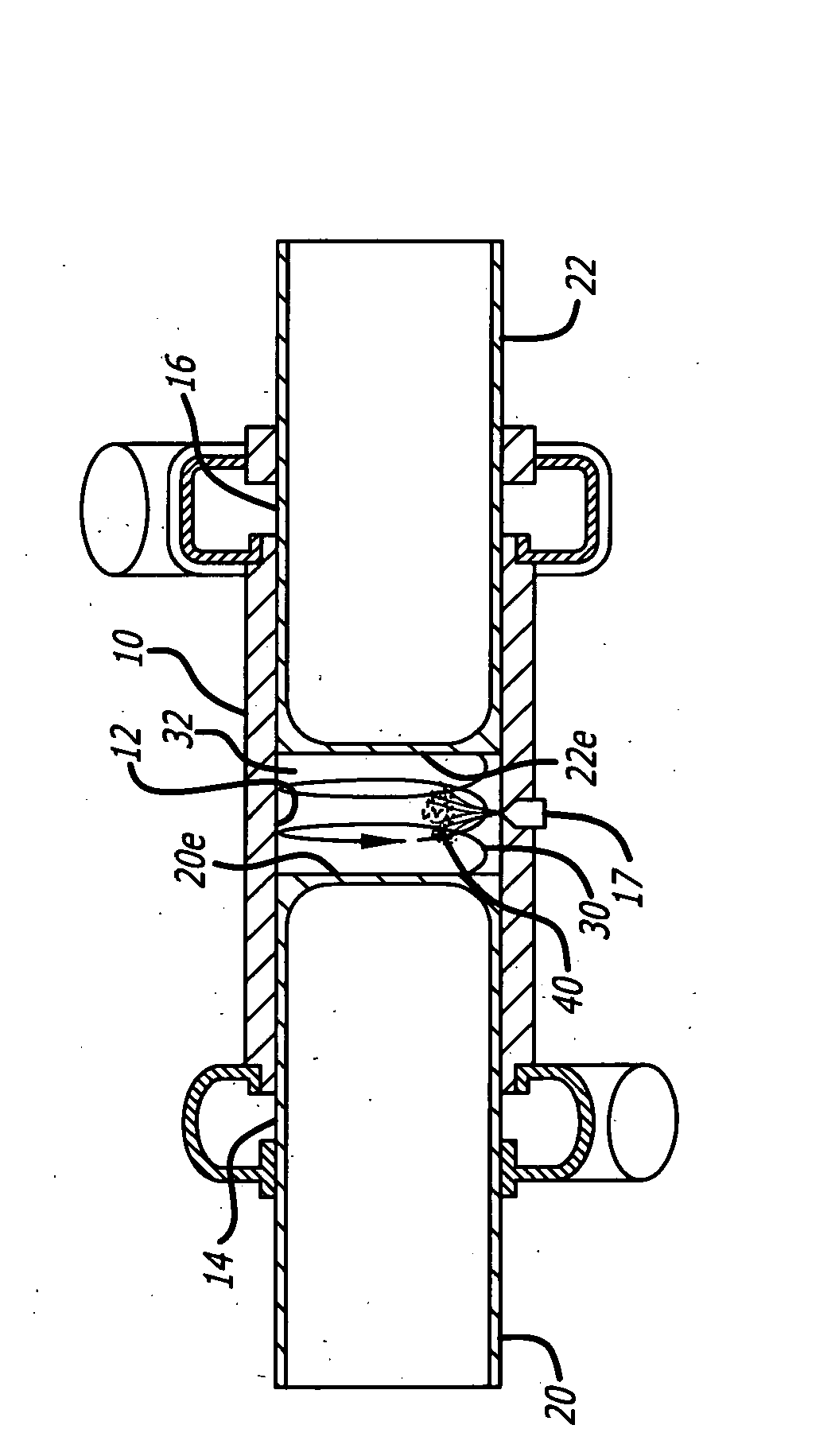

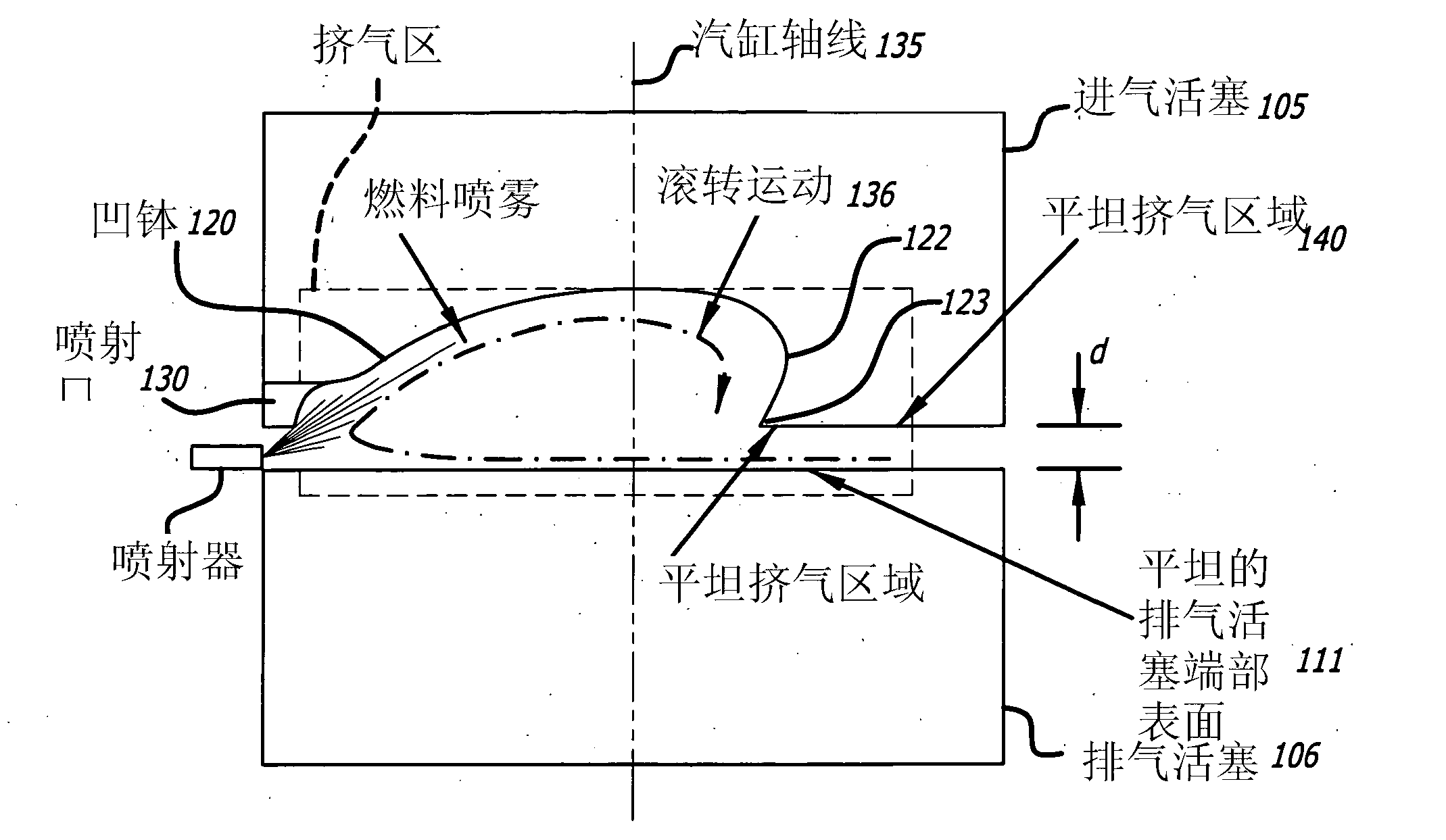

[0029] Within the combustion chamber configuration to be described, an internal combustion engine includes at least one cylinder with longitudinally separated exhaust and intake ports. See, for example, cylinder 10 shown in FIGS. 1 and 2 . A pair of pistons are opposedly disposed within the bore of the cylinder, and a combustion chamber structure is defined between opposed end surfaces of the pistons as they move toward a top dead center position. A circumferential region defines a periphery on each of these end surfaces. The combustion chamber includes a cavity defined between end surfaces and has at least one opening through which fuel is injected (hereinafter referred to as "injection port"), the opening extending at least substantially in the radial direction of the cylinder and opening into the cavity.

[0030] During operation of an internal combustion engine, as the pistons approach top dead center TDC, one or more squish regions direct a flow of compressed air (known...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com