welding device

A welding device and arc welding method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as arc instability, achieve stable droplet growth, prevent instability, and high welding stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

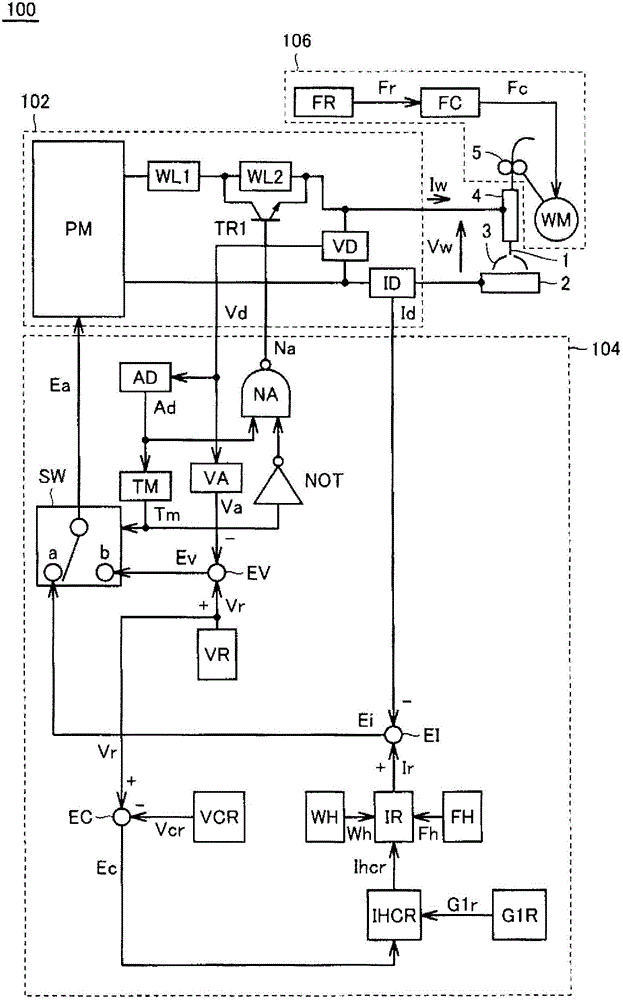

[0037] figure 1 It is a block diagram of the welding apparatus concerning Embodiment 1.

[0038] refer to figure 1 , The welding device 100 includes: a power circuit 102 , a power control device 104 , a welding wire feeding device 106 , and a welding torch 4 .

[0039] The power supply control device 104 controls the power supply circuit 102 so that the welding current Iw and the welding voltage Vw output to the welding torch 4 become values suitable for welding.

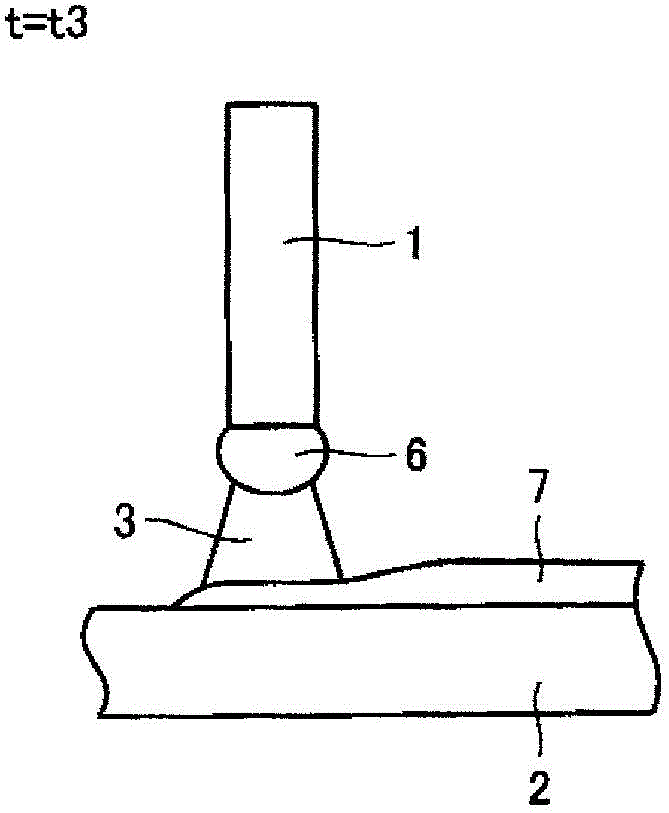

[0040] The welding wire feeding device 106 feeds the welding wire 1 to the welding torch 4 . Although not shown in the figure, shielding gas mainly composed of carbon dioxide gas is released from the tip portion of the welding torch 4 . An arc 3 is generated between the welding wire 1 protruding from the tip of the welding torch 4 and the base material 2 , and the welding wire 1 is melted to weld the base material 2 . The wire feeding device 106 includes a feeding speed setting circuit FR, a feeding control ci...

Embodiment approach 2

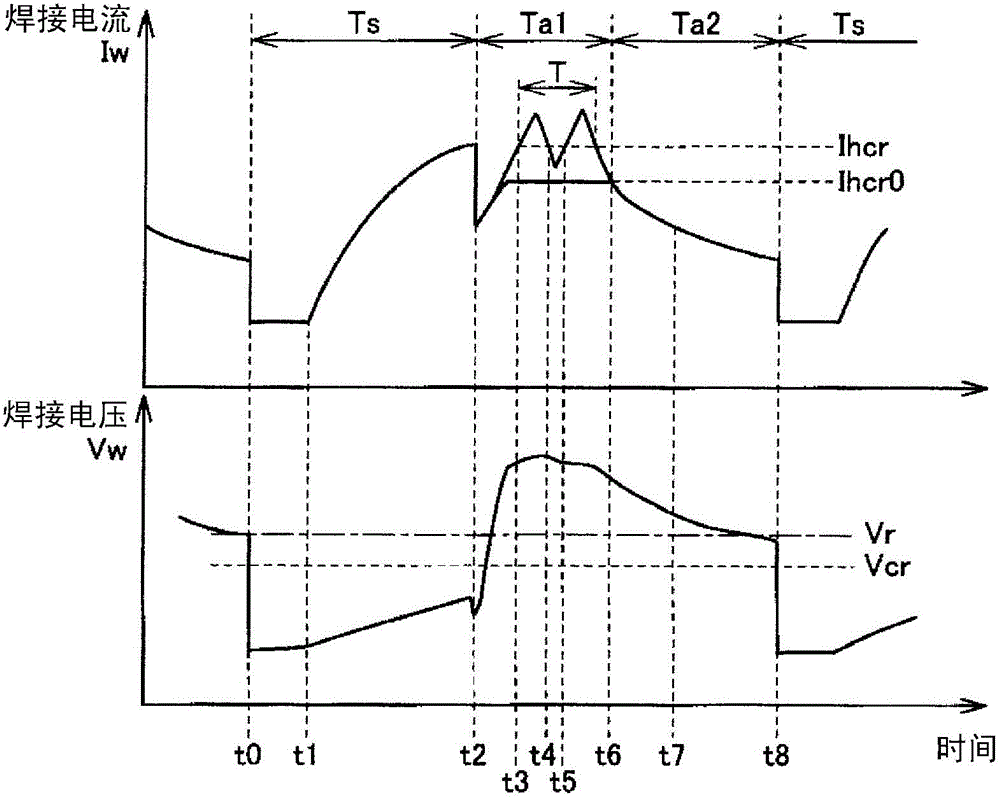

[0098] In Embodiment 1, the magnitude of the high-level current is changed based on the voltage difference between the set voltage Vr and the reference voltage Vcr, but in Embodiment 2, based on the voltage difference between the set voltage Vr and the reference voltage Vcr, voltage difference to make figure 2 The period of the indicated high-level current (the first arc period Ta1 ) changes.

[0099] Figure 7 It is a block diagram showing the structure of 100 A of welding apparatuses concerning Embodiment 2. In the following description, only the parts different from Embodiment 1 will be described, and the same symbols as those in Embodiment 1 will be assigned the same symbols and will not be described repeatedly.

[0100] refer to Figure 7 , The welding device 100A includes: a power circuit 102 , a power control device 104A, a welding wire feeding device 106 and a welding torch 4 .

[0101] The power control device 104A is in figure 1 In the configuration of the ill...

Embodiment approach 3

[0110]In the first embodiment, only the amplitude center current setting signal Ihcr is increased or decreased according to the voltage difference (Vr-Vcr), and in the second embodiment, only the first arc period Ta1 is increased or decreased.

[0111] In Embodiment 3, upper and lower thresholds are set for the voltage difference, and only the amplitude center current setting signal Ihcr is increased or decreased until the threshold value is reached. For the voltage difference exceeding the threshold value or the voltage difference smaller than the threshold value, only the first arc period Ta1 increases and decreases.

[0112] Figure 8 It is a block diagram showing the structure of the welding apparatus 100B which concerns on Embodiment 3. In the following description, only the parts different from Embodiment 1 will be described, and the same symbols as those in Embodiment 1 will be assigned the same symbols and will not be described repeatedly.

[0113] refer to Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com