Fixture and method for quick spot welding of thermistor to battery protection board

A battery protection board, thermistor technology, applied in resistance welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of low quality, slow production speed, inaccurate spot welding position, etc., to reduce labor intensity, improve Production efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

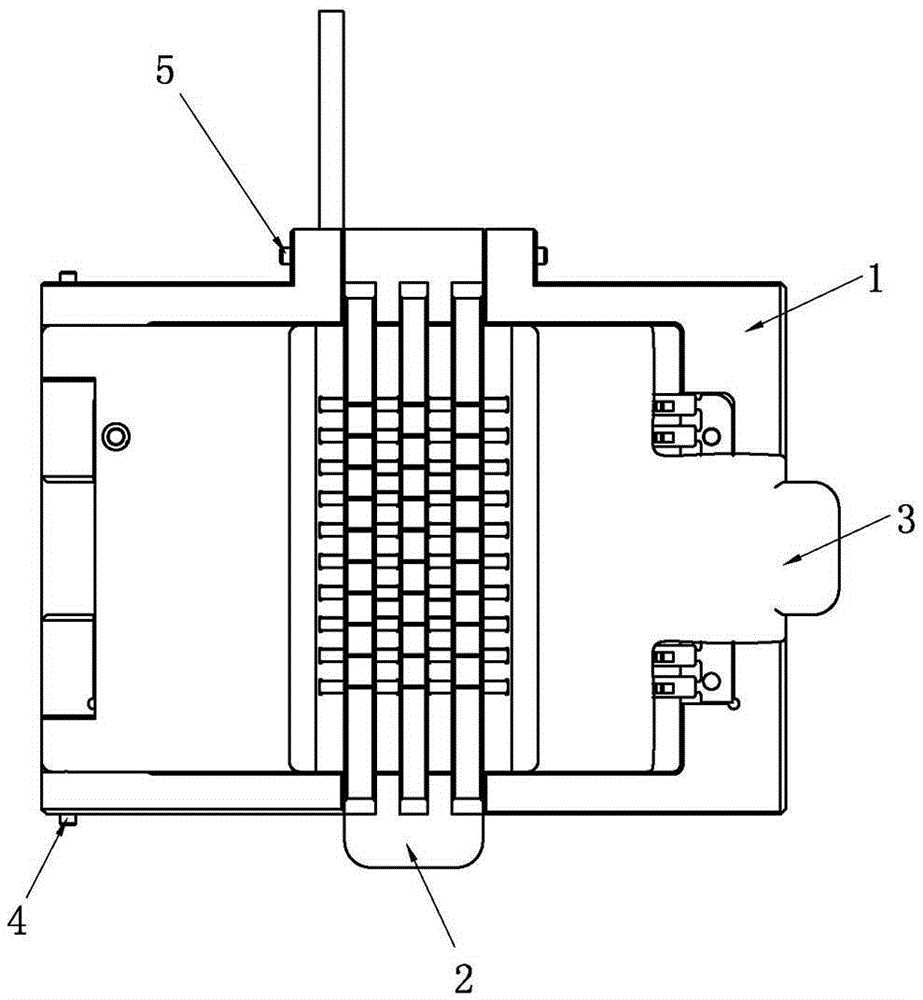

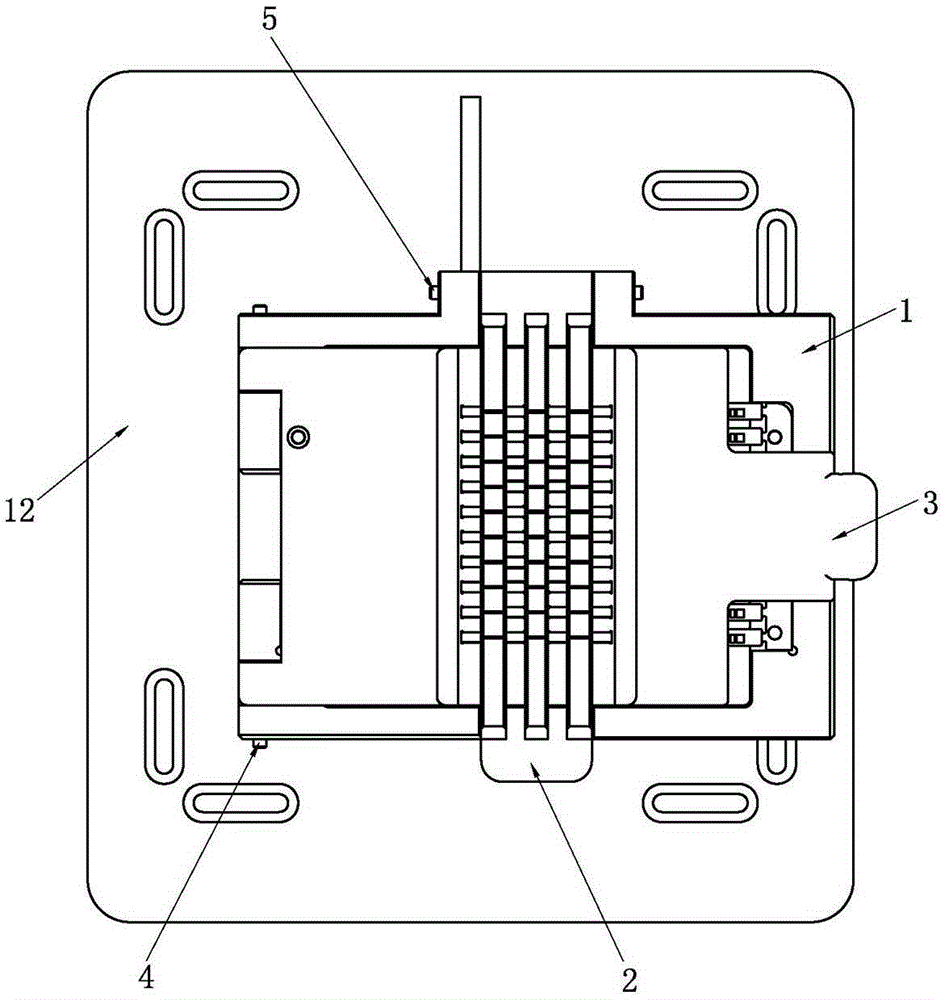

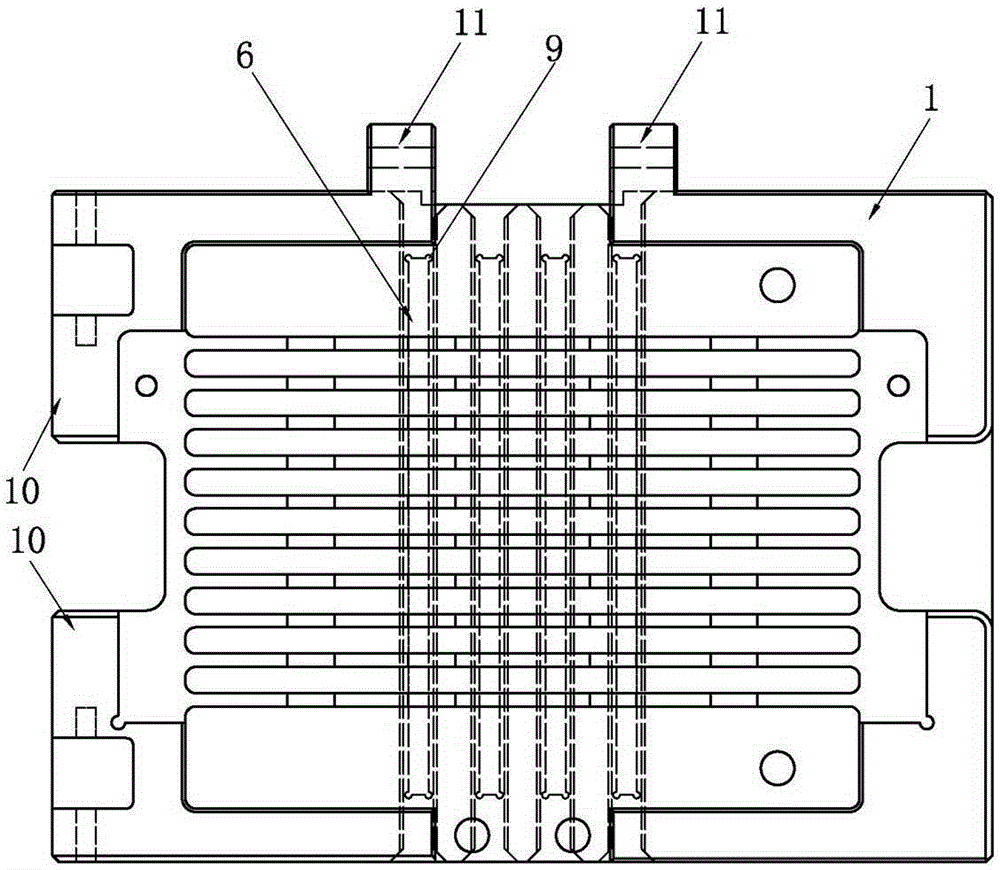

[0039] See Figure 1 to Figure 5 , the present invention provides a fixture for quickly spot-welding a thermistor to a battery protection plate, comprising a load base 1, a positioning plate 2 and a pressure plate 3, one side of the pressure plate 3 passes through a pin shaft 4 and one side of the load base 1 The sides are hinged, and one side of the positioning plate 2 is hinged to one side of the loading base 1 through the pin shaft 5. The positioning plate 2 is arranged on the pressing plate 3, and the positioning plate 2 and the pressing plate 3 are crossed. 1 is provided with a pit 6 for accommodating the splicing plate, the pressing plate 3 is provided with a through hole 7 at the intersection with the positioning plate 2, and the positioning plate 2 is provided with at least one positioning through hole 8 for the thermistor to be inserted into.

[0040] Preferably, a positioning hole 9 for positioning the splicing plate is provided in the pit 6. When multiple battery pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com