A cold drawing die grinding device and method

A mold and cold drawing technology, which is applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as difficulty in ensuring the coaxiality of the grinding head and the die hole, uneven grinding force of the die hole, and poor repair effect. Achieve the effect of improving grinding efficiency and grinding quality, balancing grinding force and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

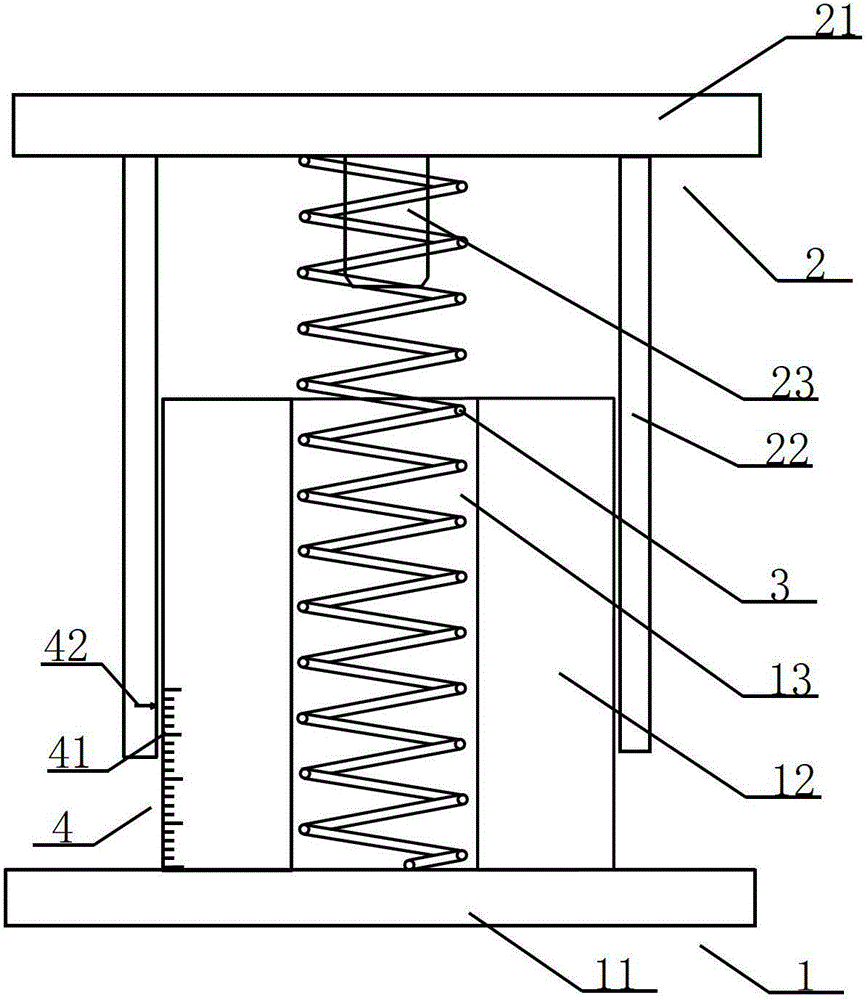

[0016] Such as figure 1 The shown cold drawing die grinding device of the present invention includes a stand 1, a floating platform 2 and an elastic compression spring 3. The stand 1 includes a base 11 and a column 12 fixed on the base, and an inner hole 13 is arranged in the middle of the column; The floating platform 2 includes a working platform 21 and a sleeve 22 fixed on the working platform. The inner diameter of the sleeve is slightly larger than the outer diameter of the column and is sleeved outside the column 12. The two are in clearance fit, and a positioning pin 23 is fixed in the middle of the sleeve. The spring 3 is arranged in the inner hole of the column 12 , and one end of the spring 3 is sleeved on the positioning pin 23 .

[0017] The pressure indicator 4 is composed of a fixed ruler 41 arranged on the column 12 and a moving ruler 42 arranged on the casing 22. The two rulers are parallel to each other, the fixed ruler is marked with a scale, and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com