Two-axis manipulator for press line and working process of two-axis manipulator

A technology of manipulators and production lines, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

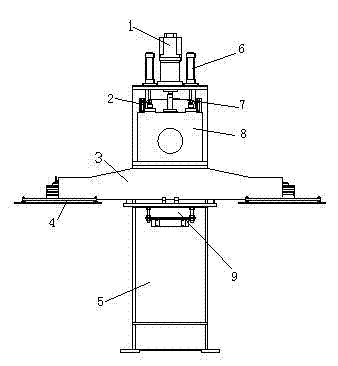

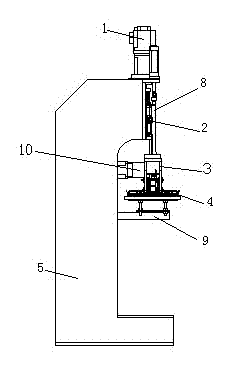

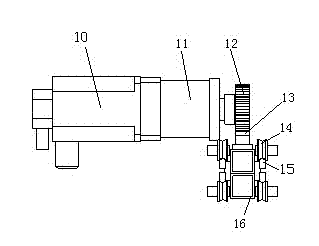

[0040] The two-axis manipulator of the present invention comprises a frame 5, an X-axis transmission system, a Y-axis transmission system, an X-axis support 3, a buffer table 9, and a control system. The Y-axis servo motor 1 is fixed on the top of the frame 5, connected with the ball screw through the coupling, and the ball nut is fixed on the sliding platform 8, and the sliding platform 8 is composed of the Y-axis servo motor 1 through the ball screw nut pair 7 The drive realizes its up and down movement, and the guidance of the sliding platform 8 is completed by the Y-axis linear guide rail 2 fixed on the frame 5; the X-axis transmission system includes an X-axis servo motor 10, a reducer 11, an X-axis support 3, a cross bar, Composed of a transmission mechanism and a guide mechanism, the X-axis support 3 is fixedly connected to the Y-axis sliding platform 8 with its upper joint surface, and the X-axis servo motor 10 is fixedly connected to the X-axis support 3 through a redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com