High-intensity folding vehicle head component

A high-strength, front-end technology, applied in the field of car parts, can solve problems such as insufficient strength of the fixing method, insufficient strength and rigidity, and poor folding effect, so as to improve safety and usability, compact folding size, and improve the overall connection intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

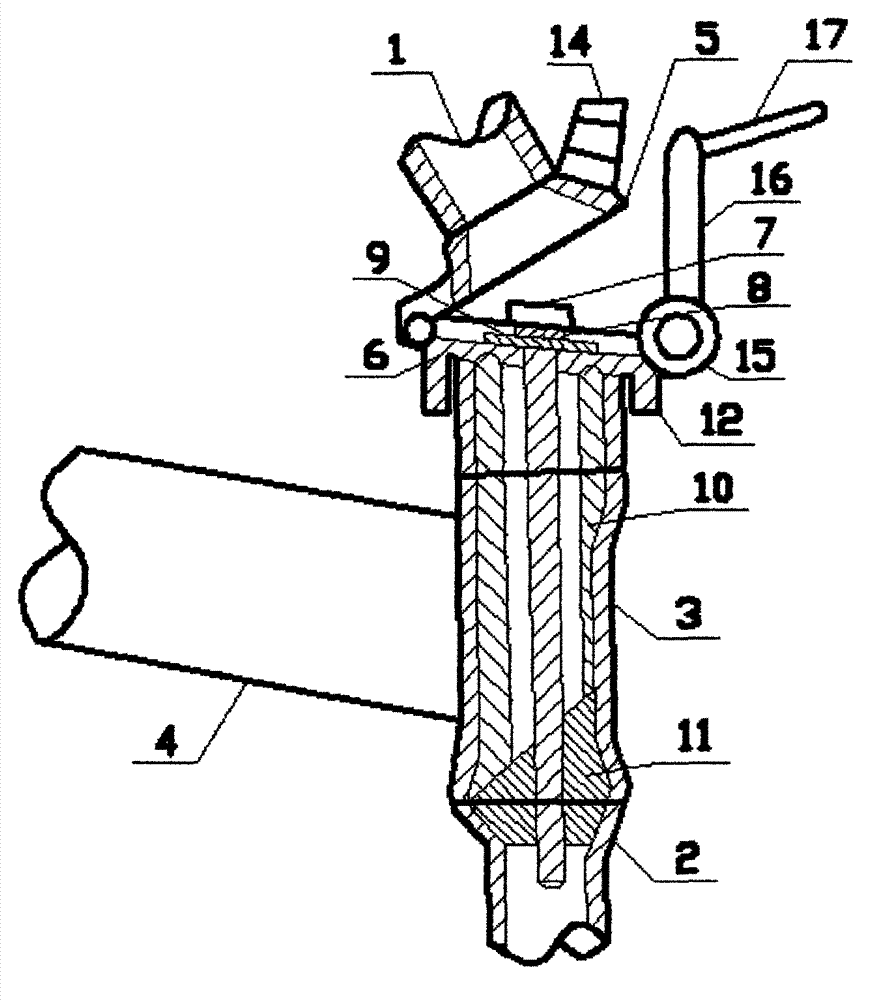

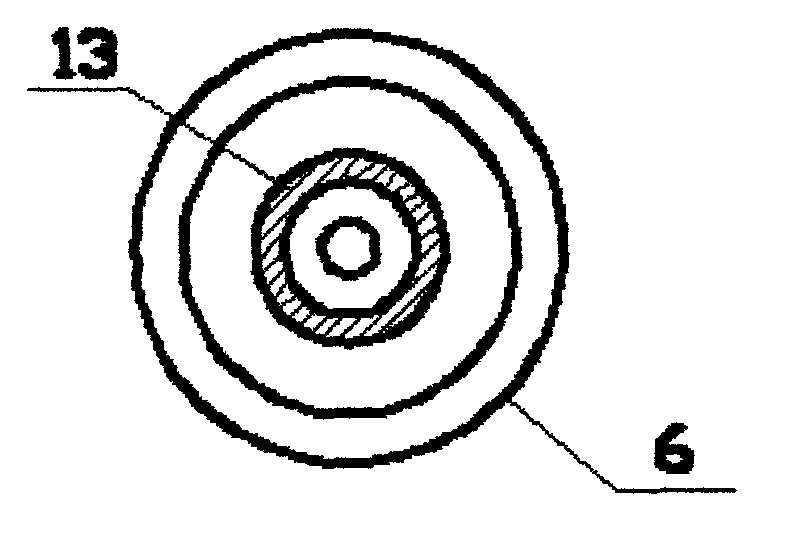

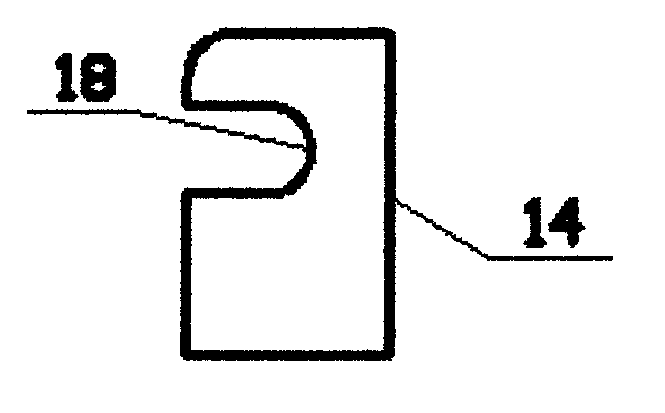

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a high-strength folding front assembly includes a standpipe 1, a front fork 2, a frame head pipe 3, and a horizontal pipe 4 welded to the frame head pipe 3. The standpipe 1 and the car frame A standpipe folder is also provided at the junction of the frame head pipe 3. The standpipe folder includes an upper joint 5 and a lower joint 6. The upper joint 5 is welded together with the lower end nozzle of the standpipe 1, and the lower joint 6 is locked by a fixing assembly. At the nozzle of the upper end of the head tube 3 of the frame, the fixing assembly includes a long-diameter screw 7, a spring washer 8, a metal washer 9 and a positioning tube 10, and an inclined fixing block 11 is fixed inside the front fork 2, and the inside of the inclined fixing block 11 is provided with a There are threaded holes, and the long-diameter screw 7 passes through the spring washer 8, the metal washer 9 and the lower joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com