Material belt transporting device

A transportation device and material belt technology, applied in the field of material belt transportation devices, can solve the problems of blocking workpiece transportation, affecting transportation quality, and small distance, and achieving the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

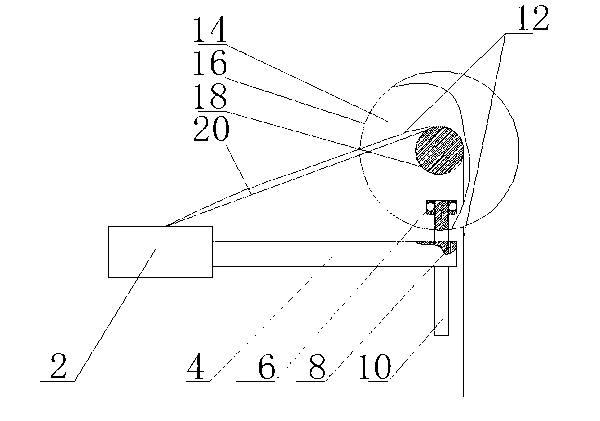

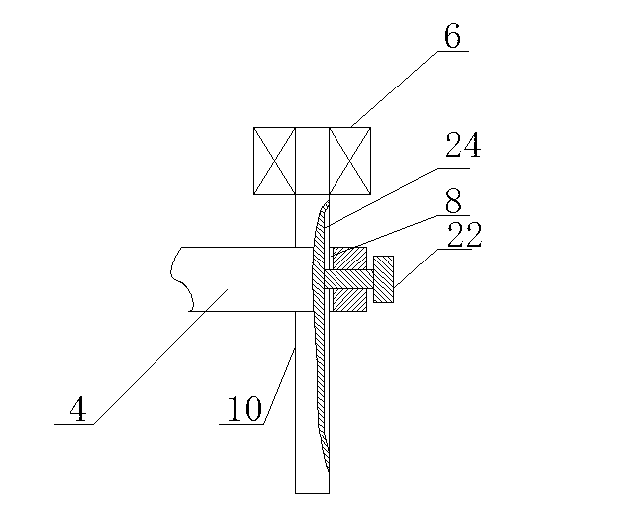

[0021] Such as figure 1 As shown, the strip conveying device of the present invention includes a workbench 2, an I-shaped wheel 14 and a material strip 12, the I-shaped wheel 14 includes two side plates 16, and a roller 18 sandwiched between the side plates 16, and the material strip 12 passes through The workbench 2 and the roller 18 are transported. In a preferred technical solution of the present invention, the material strip 12 is transported downward from the workbench 2 through the roller 18 and along the tangential direction of the roller 18. This mode of transportation is adopted , under the action of the friction force of the roller 18, the material strip 12 can be moved without applying any external force. In the process of transportation, the material strip 12 may be attached to the roller 18 and then be involved in the roller 18 because the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com