Cavity sound-absorbing sheet

A cavity and sound-absorbing technology, which is applied in the field of sound-absorbing materials, can solve problems such as failure to match the acoustic characteristic impedance of sound-absorbing materials, achieve the effect of improving language clarity and ensuring sound absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

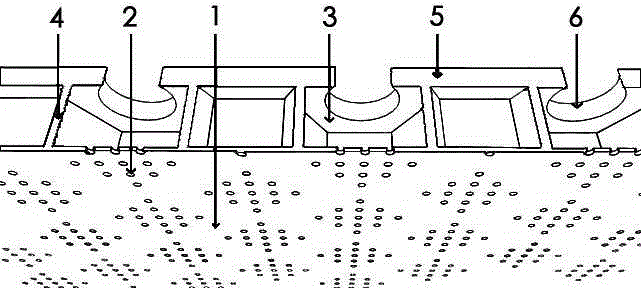

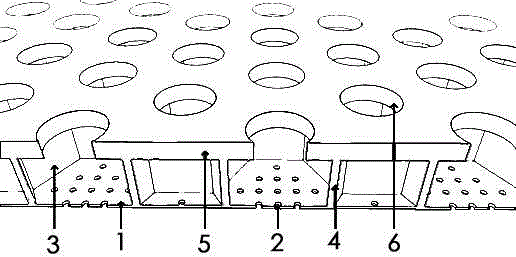

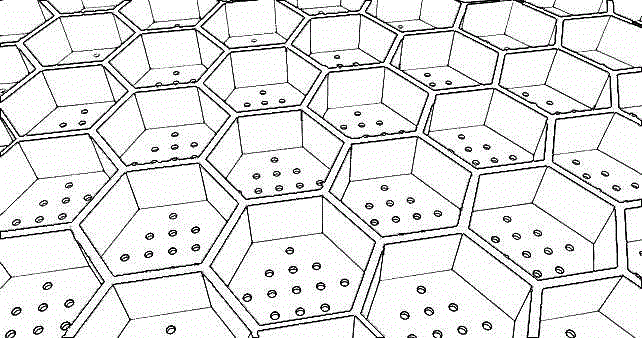

[0024] Such as figure 1 , figure 2 , image 3 As shown, a cavity sound-absorbing panel includes a film 1, a cavity partition 4, and a back panel 5. It is a honeycomb panel with an inner cavity 3 structure.

[0025] The cavity partition 4 is a grid plate structure, one side of the cavity partition 4 is provided with a film 1, and the other side of the cavity partition 4 is provided with a back plate 5; A plurality of inner cavities 3 are formed between it and the back plate 5 . The cavity separator 4 is a honeycomb grid plate structure with hexagonal lattice units, and the inner cavity 3 is a cavity with a hexagonal cross section.

[0026] A plurality of ultramicropores 2 are opened on the film 1 at positions corresponding to the inner cavity 3 . The ultramicro holes 2 are tiny round holes with a diameter of 0.2-0.8 mm. The combined structure of the ultramicropores 2 distributed on the film 1 and the inner cavity 3 satisfies the Helmholtz resonance principle.

[0027] A ...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that the inner cavity 3 is closed, that is, no round hole is provided on the back plate 5 . The depth of the closed inner cavity 3 is controlled at 50-100 mm, forming a sound-absorbing component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com