Guide-rail-type arc-shaped automatic door system

An automatic door and guide rail technology, used in revolving doors, door/window accessories, buildings, etc., can solve problems such as warping deformation, high noise, difficult maintenance, etc., to eliminate distortion, solve warping deformation, and ensure beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

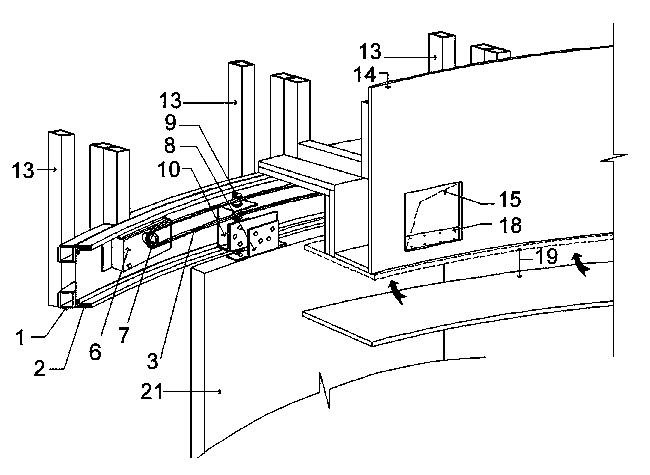

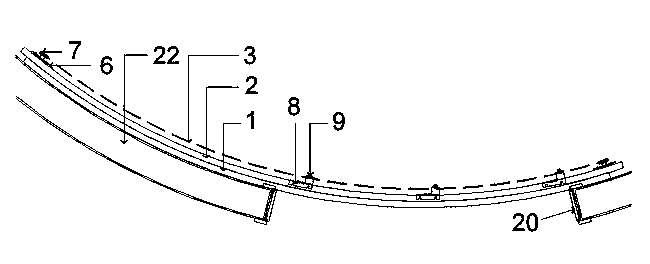

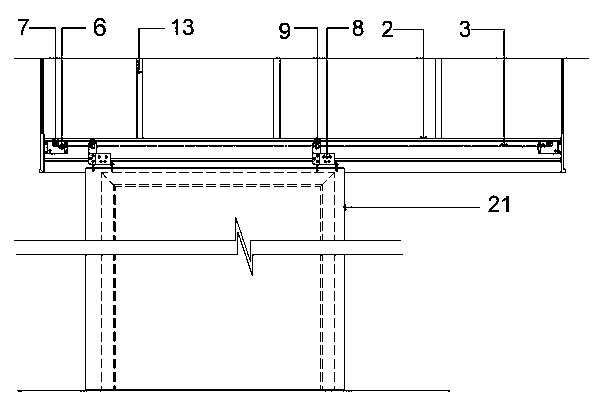

[0023] Example: such as Figure 1 to Figure 6 As shown, a guide rail arc-shaped automatic door system includes a base support 1, a guide rail 2, an endless belt 3, a main pulley assembly, a secondary pulley assembly, and an automatic door 21. The base support 1 and the guide rail 2 are stretched and bent according to the same arc modulus, and the base support 1 and the guide rail 2 are welded into a whole. The main pulley assembly is fixed on the guide rail 2, and the secondary pulley assembly is movably installed on the guide rail 2.

[0024] Such as Figure 7 , Figure 8 , Figure 9 As shown, the main pulley assembly includes a main pulley 7 and a main pulley structure 6, and the main pulley 7 is installed on the main pulley structure 6, as Figure 10 , Figure 11 , Figure 12 As shown, the secondary pulley assembly includes a secondary pulley 9, a secondary pulley fixture 10, and an automatic door fixture 8. The secondary pulley 9 is installed on the secondary pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com